Europium-erbium double-doped zirconium dioxide light-emitting film and preparation method and application thereof

A technology of zirconium dioxide and luminescent thin films, applied in the field of thin film electroluminescent devices and their preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

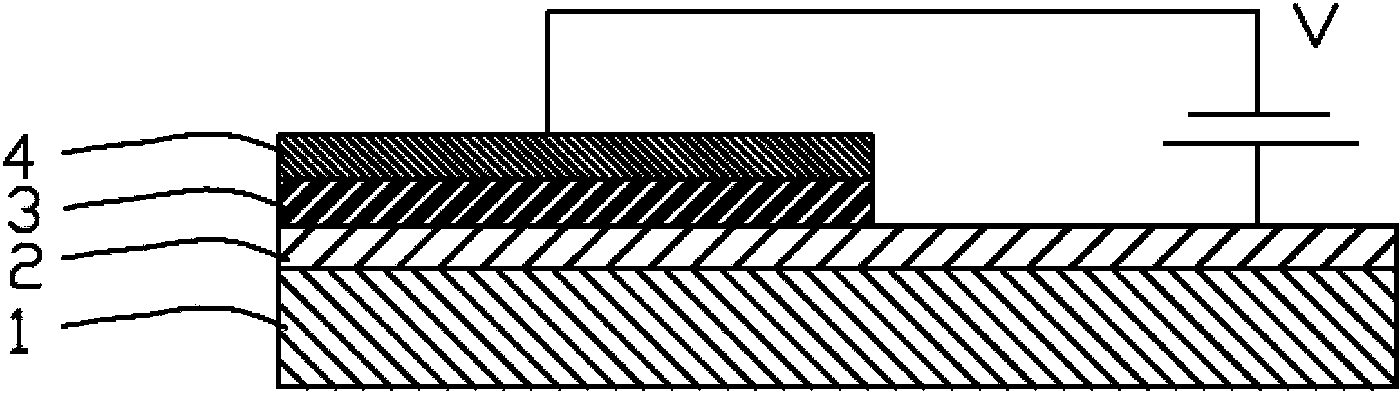

[0032] The preparation method of the above-mentioned europium-erbium double-doped zirconium dioxide luminescent film comprises the following steps:

[0033] Step S11, according to ZrO 2 :xEu 3+ ,yEr 3+ The stoichiometric ratio of each element will ZrO 2 , Eu 2 o 3 and Er 2 o 3 The powder, after mixing, is sintered at 900°C to 1300°C to obtain the target;

[0034] Load the substrate into the reaction chamber of the chemical vapor deposition equipment, and set the vacuum degree of the reaction chamber to 1.0×10 -3 Pa~1.0×10 -5 Pa.

[0035] In this embodiment, the substrate is indium tin oxide glass (ITO). It can be understood that in other embodiments, it can also be fluorine-doped tin oxide glass (FTO), aluminum-doped zinc oxide (AZO) or indium-doped glass. zinc oxide (IZO); the substrate was ultrasonically cleaned with toluene, acetone and ethanol for 5 minutes, then rinsed with distilled water, air-dried with nitrogen, and sent to the reaction chamber.

[0036] Pre...

Embodiment 1

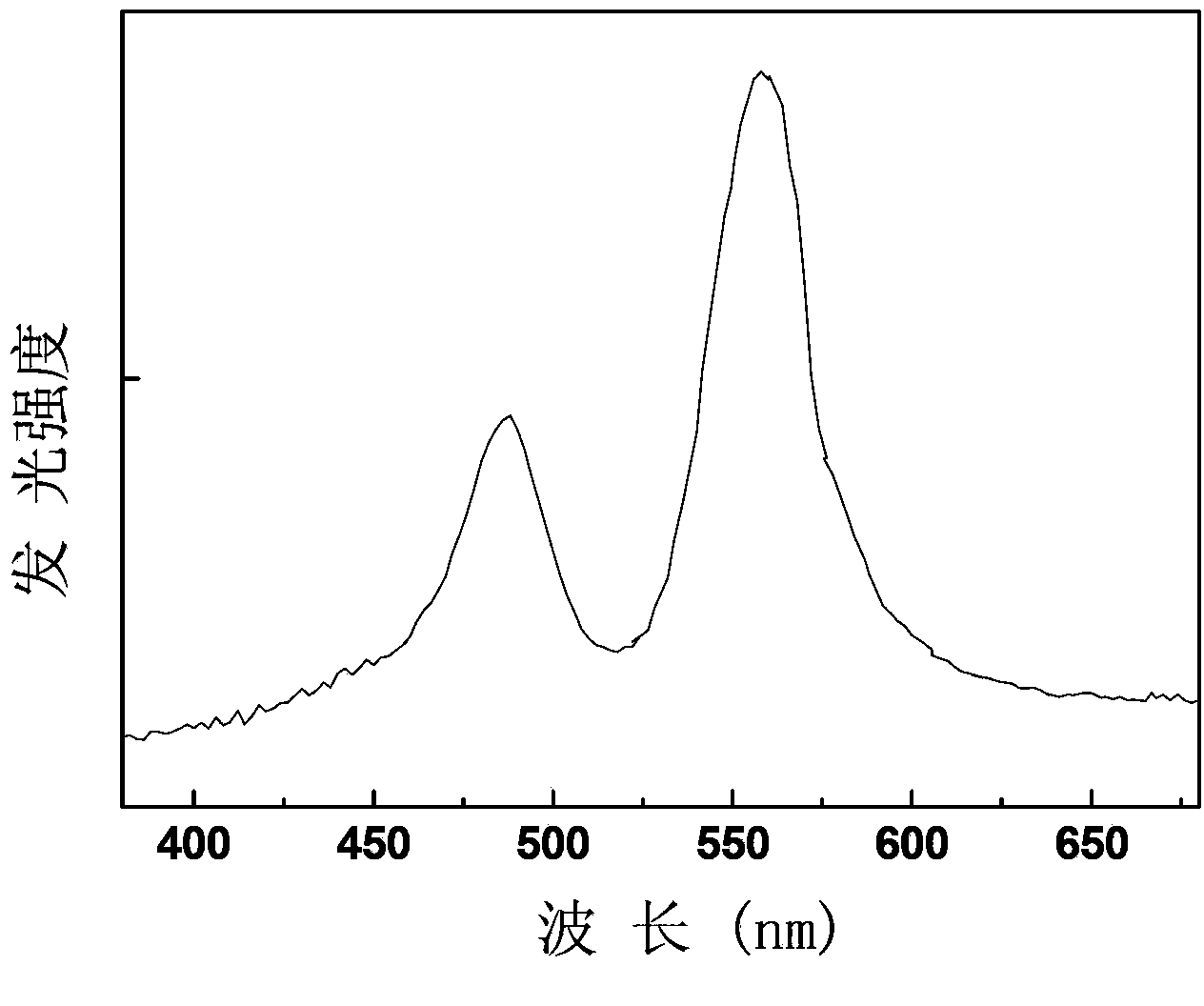

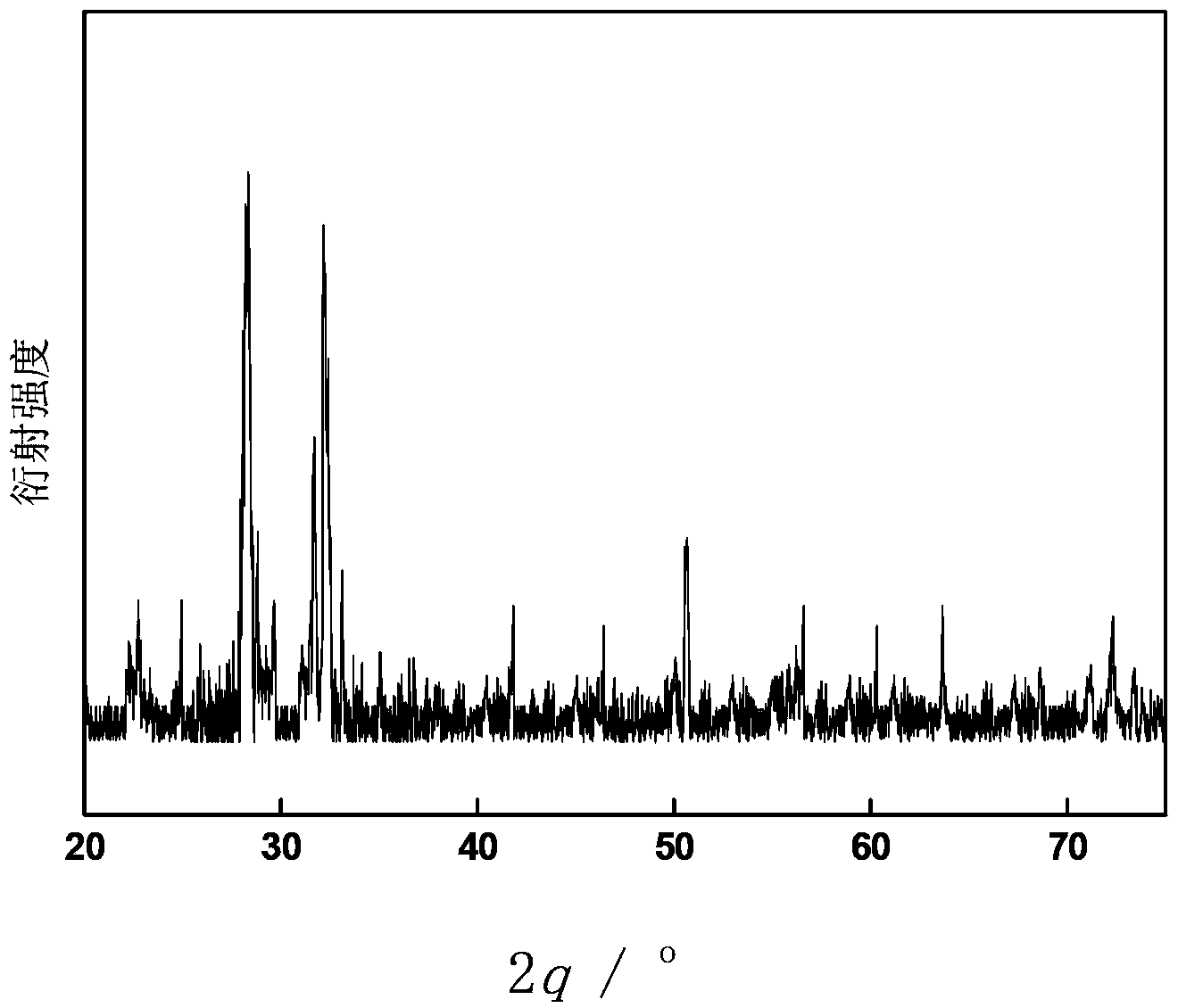

[0058] 0.95mmol ZrO 2 , 0.01 mmol Eu 2 o 3 and 0.015 mmol Er 2 o 3 After the powder is uniformly mixed, it is sintered at 1250°C to form a ceramic target with a diameter of 50 and a thickness of 2mm in the shape of a round cake, and the target is placed in a vacuum chamber, and the substrate is ITO glass. Toluene, acetone and ethanol were ultrasonically cleaned for 5 minutes, then rinsed with distilled water, treated with oxygen plasma, and placed in a vacuum chamber. Set the distance between the target and the substrate as 60mm, and use a mechanical pump and a molecular pump to pump the vacuum of the cavity to 5.0×10 -4 Pa; Oxygen is used as the working gas flow, the working gas flow rate is 20sccm, the pressure is adjusted to 3.0Pa, the substrate temperature is 500°C, and the pulse laser energy is 150W, and the deposition of the film is started. The thickness of the film is deposited to 150nm, and the general chemical formula of the europium-erbium double-doped zirconia...

Embodiment 2

[0064] 0.98mmol ZrO 2 , 0.005 mmol Eu 2 o 3 and 0.005 mmol Er 2 o 3 After the powder is uniformly mixed, it is sintered at 900 ° C to form a ceramic target with a diameter of 50 and a thickness of 2 mm, and the target is placed in a vacuum chamber, and the substrate is ITO glass. Ultrasonic cleaning for 5 minutes, then rinsed with distilled water, treated with oxygen plasma, and placed in a vacuum chamber. Set the distance between the target and the substrate as 60mm, and use the mechanical pump and the molecular pump to pump the vacuum of the cavity to 1.0×10 -3 Pa; Oxygen is used as the working gas flow, the working gas flow rate is 10 sccm, the pressure is adjusted to 0.5 Pa, the substrate temperature is 250°C, and the pulse laser energy is 80W, and the deposition of the film is started. The thickness of the film is deposited to 50nm, and the general chemical formula of the europium-erbium double-doped zirconia luminescent film obtained by taking out the sample is ZrO ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com