Process for manufacturing centrifugally-cast easy-cutting high-speed steel roll

A centrifugal casting and manufacturing process technology, applied in the field of metallurgical roll manufacturing, can solve problems such as difficult tool processing, high-speed steel roll processing, repair difficulty, high-grade carbide tool processing, etc., to reduce processing difficulty and processing cycle, improve Effect of Machinability and Machinability Improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

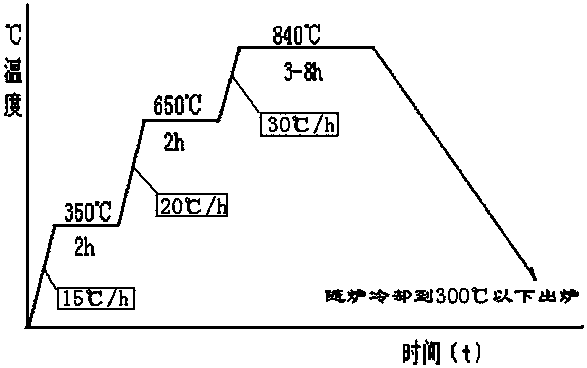

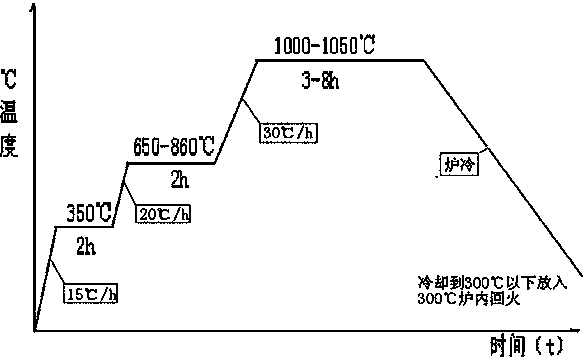

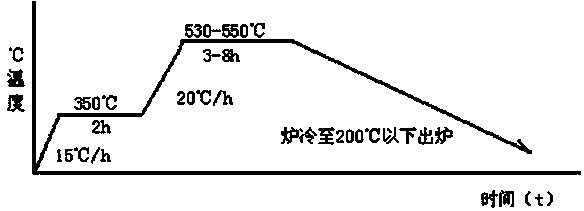

[0038] Below in conjunction with accompanying drawing, the present invention will be further described by examples.

[0039] A free-cutting high-speed steel roll manufacturing process of centrifugal casting, comprising the following process steps:

[0040] ①Chemical composition of body materials

[0041] The roll body refers to the working part of the roll, which is also a centrifugal casting layer, with a carbon content of 1.2-2.8%, a silicon content of 1.2-2.5%, a manganese content of 0.3-0.8%, a phosphorus content of less than 0.05%, a sulfur content of less than 0.04%, and other alloys Elements W, Mo, V, Cr, Nb, Ti, Ni, Al are 2-6%, 2-6%, 2-7%, 3-5%, 0.3-1.5%, 0.1-0.5%, 0- 2%, 0-4% material, to ensure that the high-speed steel matrix containing graphite can be obtained in the state of centrifugal casting and subsequent heat treatment;

[0042] ②Mold parameters

[0043] The thickness of the iron mold / thickness of the outer layer of molten iron pouring> 1.25, the machinin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com