Quick deployable oil boom

An oil boom and fast technology, which is used in the cleaning of open water surfaces, water conservancy projects, general water supply conservation, etc., can solve the problems of difficult production and installation, poor oil containment effect, and difficult maintenance, etc. Simple structure and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

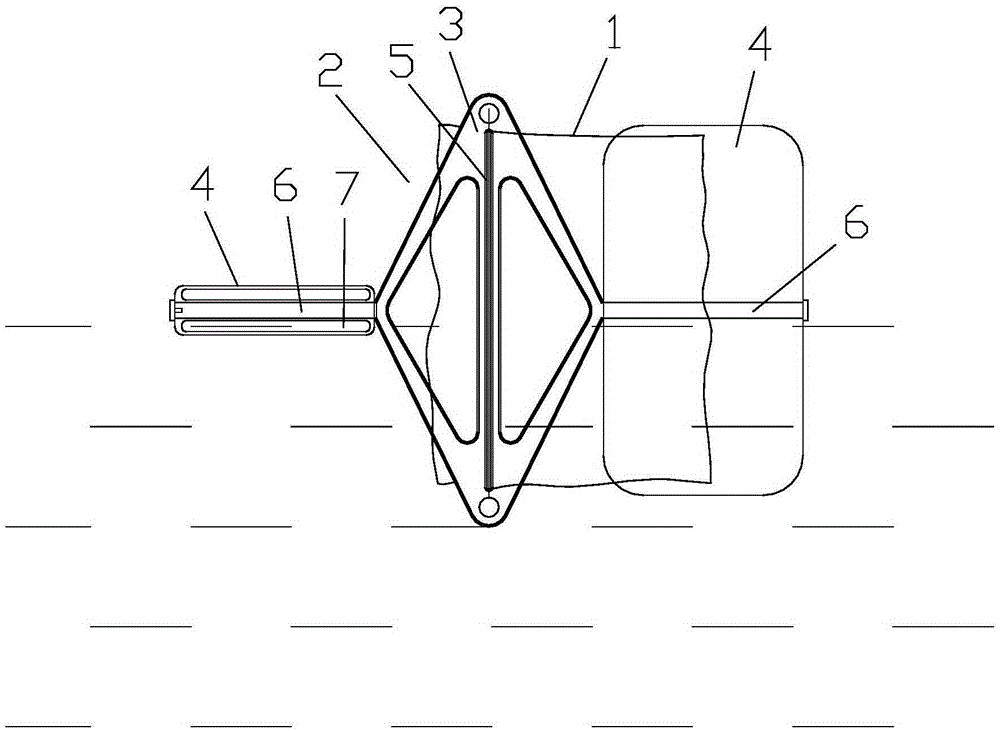

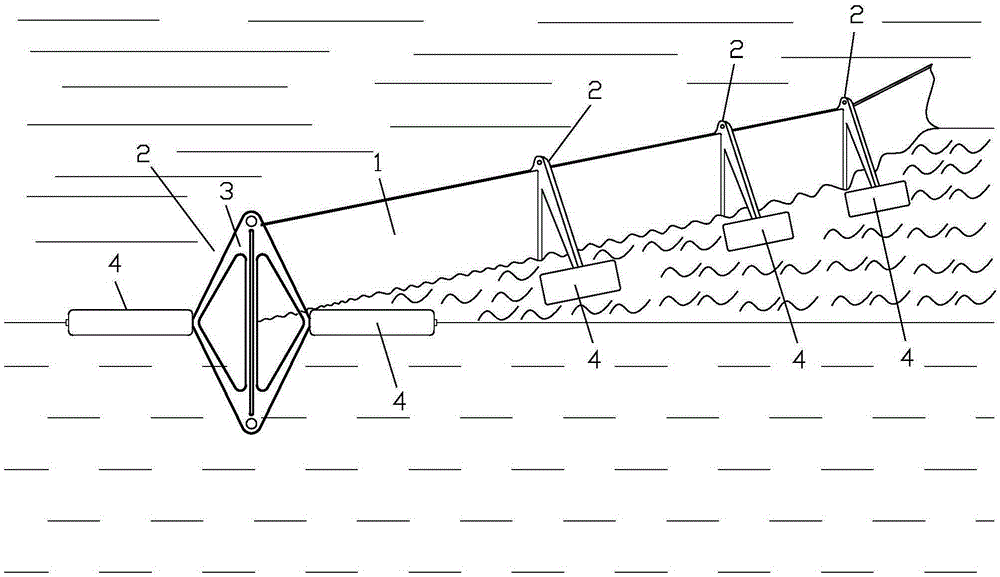

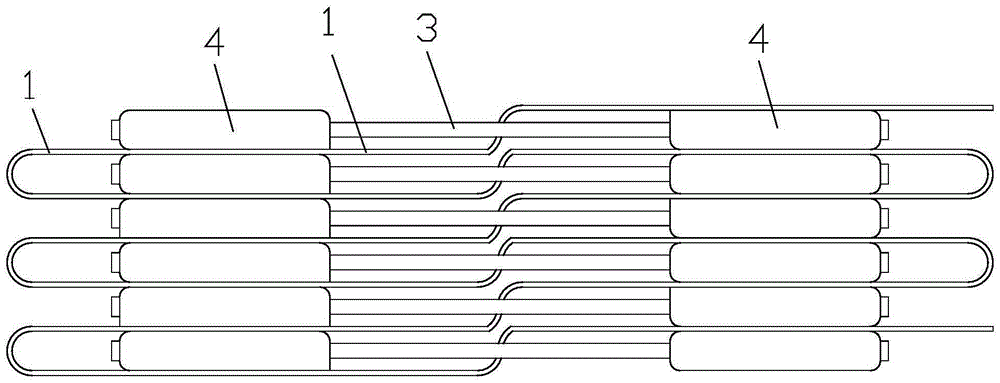

[0015] Oil booms that could have been deployed quickly, such as Figures 1 to 3 As shown, it includes a strip-shaped oil boom body 1 on which several floats 2 are installed at intervals.

[0016] The float 2 includes a plate-shaped float frame 3, and the oil boom body 1 is installed in the installation groove 5 vertically arranged in the middle of the float frame 3, the float frame 3 on both sides of the installation groove 5 is hollowed out, and the float frame 3 is symmetrically arranged on both sides Horizontal rotating shaft 6, rotatable floating board 4 is installed symmetrically on both sides of float frame 3, floating board 4 provides buoyancy for the float, floating board 4 is all installed on the corresponding rotating shaft 6, and two floating boards 4 can rotate to The flush position of the float frame 3 enables the floats 2 to be stacked together.

[0017] The hollow interior of the floating board 4 is filled with foam material 7 for improving the buoyancy of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com