A combustion chamber fuel injection and mixing device and a combustion chamber comprising the same

A fuel injection and mixing device technology, which is applied in combustion chambers, continuous combustion chambers, combustion methods, etc., can solve problems such as too many swirlers and complex structures, achieve simple and compact structure, prolong service life, and improve carbon deposition prevention performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] First introduce some terms in this technical field, among them:

[0040] Cyclone: a device that produces a rotating jet of gas;

[0041] Staged combustion: A combustion strategy, divided into axial staged combustion and radial staged combustion, refers to the mixed combustion of fuel and air in different areas, burning in different areas;

[0042] Nozzle: fuel injection and atomization device;

[0043] Fuel atomization: the process of using nozzles to turn liquid fuel into oil droplets;

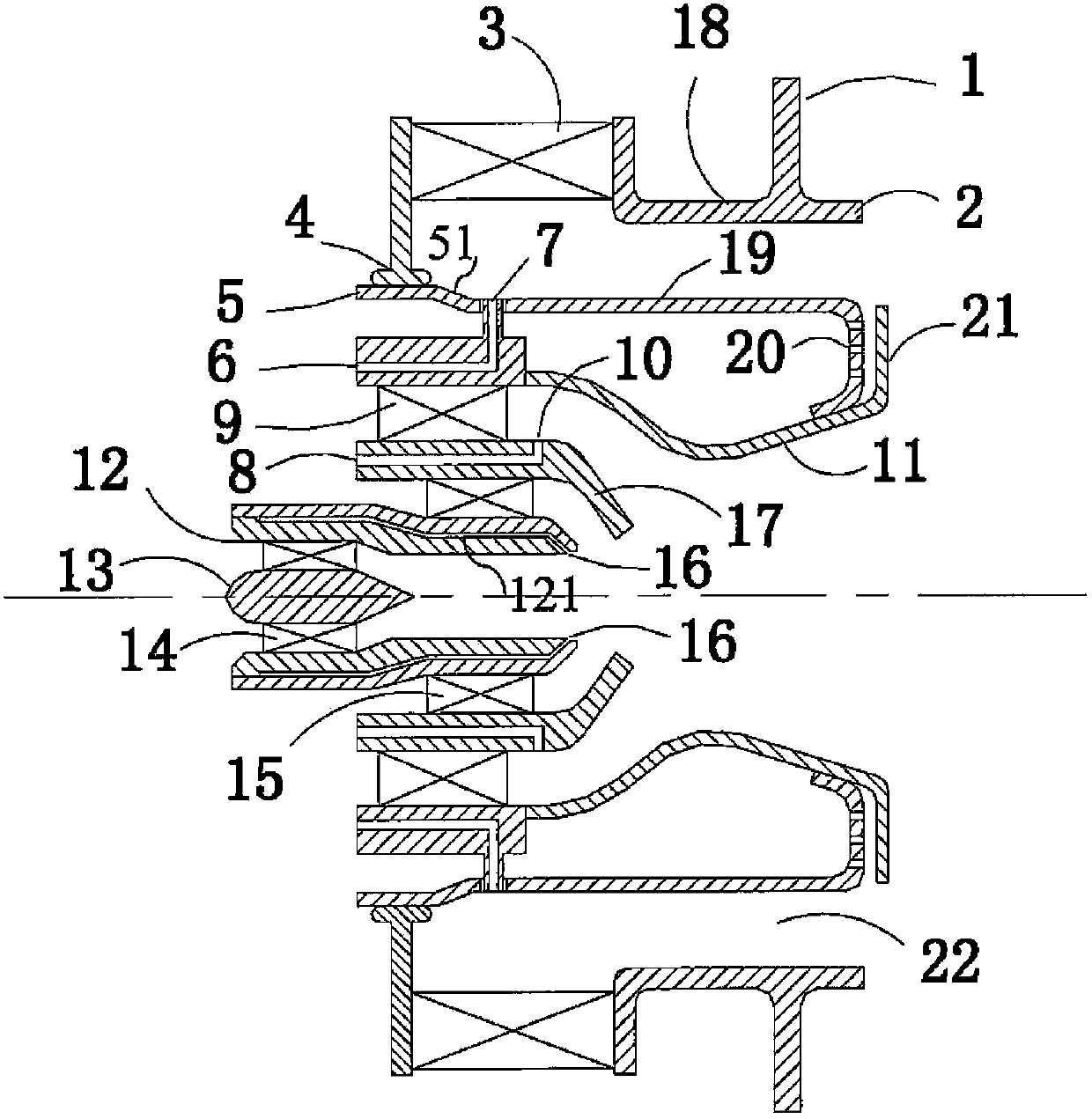

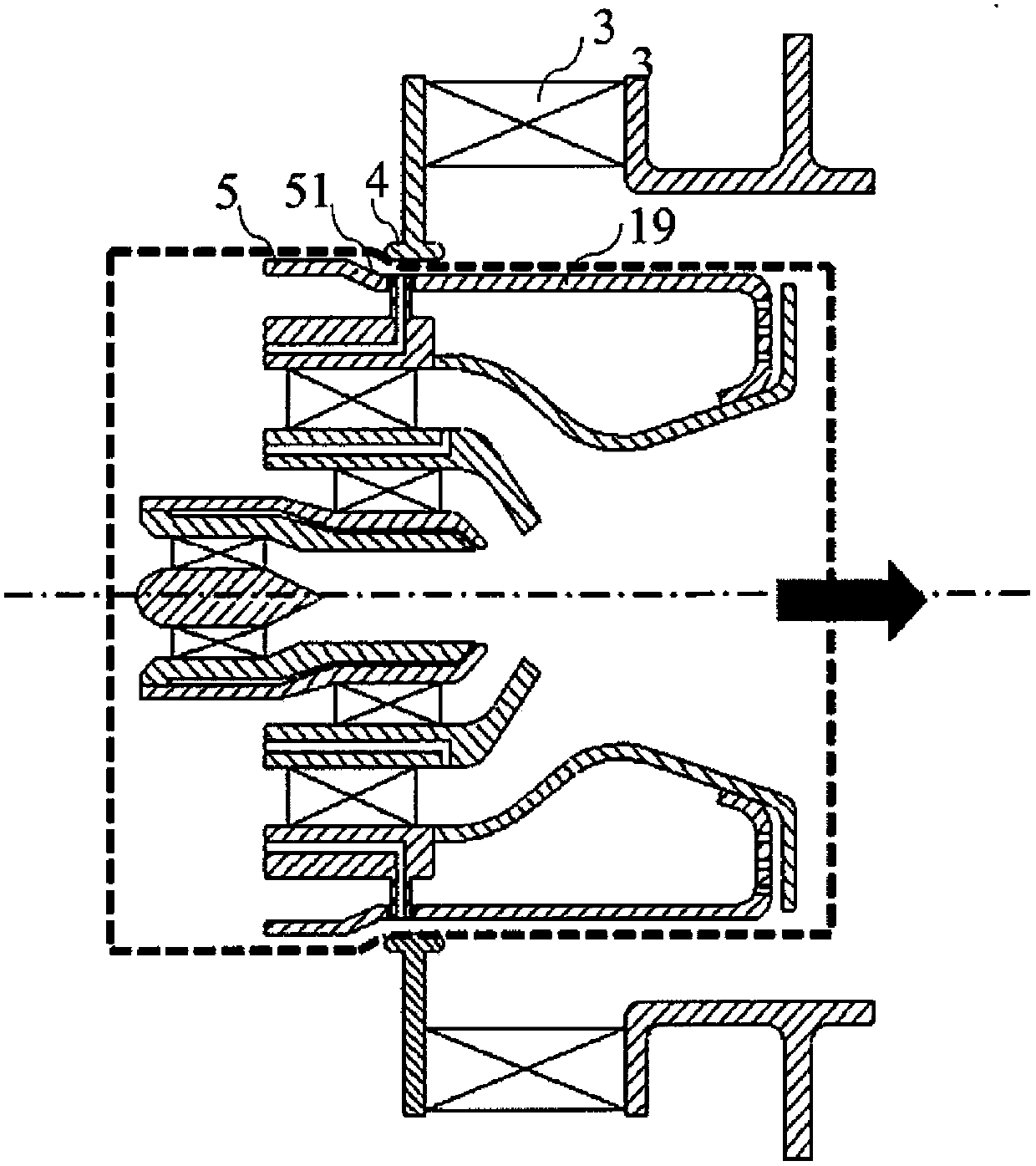

[0044] See figure 1 with figure 2 As shown, the combustion chamber fuel injection and mixing device according to the present invention adopts a fuel injection and oil-air mixing system composed of a fuel nozzle system and a swirler, and is arranged with 3 levels of independent partitioned fuel supply in a centrally graded arrangement. The whole device is connected with the transition section and the splash plate of the end wall of the head end of the flame tube of the combustion chamber by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com