Nickel-based brazing radial heat pipe heat exchanger

A heat pipe heat exchanger, brazing technology, applied in indirect heat exchangers, heat exchange equipment, tubular elements, etc., can solve the problem of increasing the radial thermal resistance of the heat exchanger, not being able to greatly adjust the wall temperature, and affecting heat transfer Capability and other issues, to achieve the effect of increasing surface temperature, improving system reliability, and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

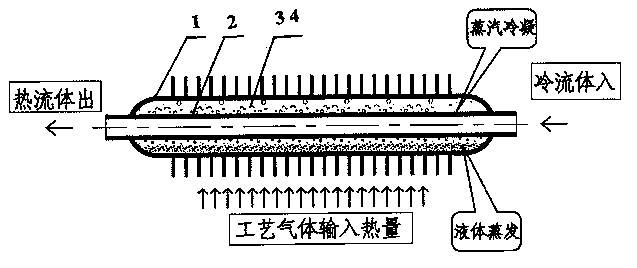

[0012] A nickel-based brazing radial heat pipe heat exchanger is composed of an outer tube 1, an inner tube 2 and a working medium 3. The inner and outer tubes are coaxial, the outer tube is a closed annular shell, the inner tube passes through the outer tube radially, a high vacuum annular gap 4 is formed between the inner tube and the outer tube, and the working medium is sealed in the annular gap . The above-mentioned outer tube adopts nickel-based brazing finned tube.

[0013] The working principle of the present invention is: the heat of the flue gas is transmitted to the working medium in the annular gap by the fins of the nickel-based brazing finned tube, and the working medium flows radially along the annular gap after evaporating, and condenses into The liquid and condensate return to the inner wall of the outer tube by gravity, so that the cycle is repeated, and the efficient transfer of heat is realized through the phase change of the working fluid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com