Small-sized full-automatic integrated corn husking and threshing and cob smashing machine

A corn threshing, fully automatic technology, applied in threshing equipment, agricultural machinery and tools, grain processing, etc., can solve the problems of increased labor for farmers, corn cob debris, and large damage to corn kernels, etc., to achieve work efficiency and High safety performance, reduced processing time, volume and light effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

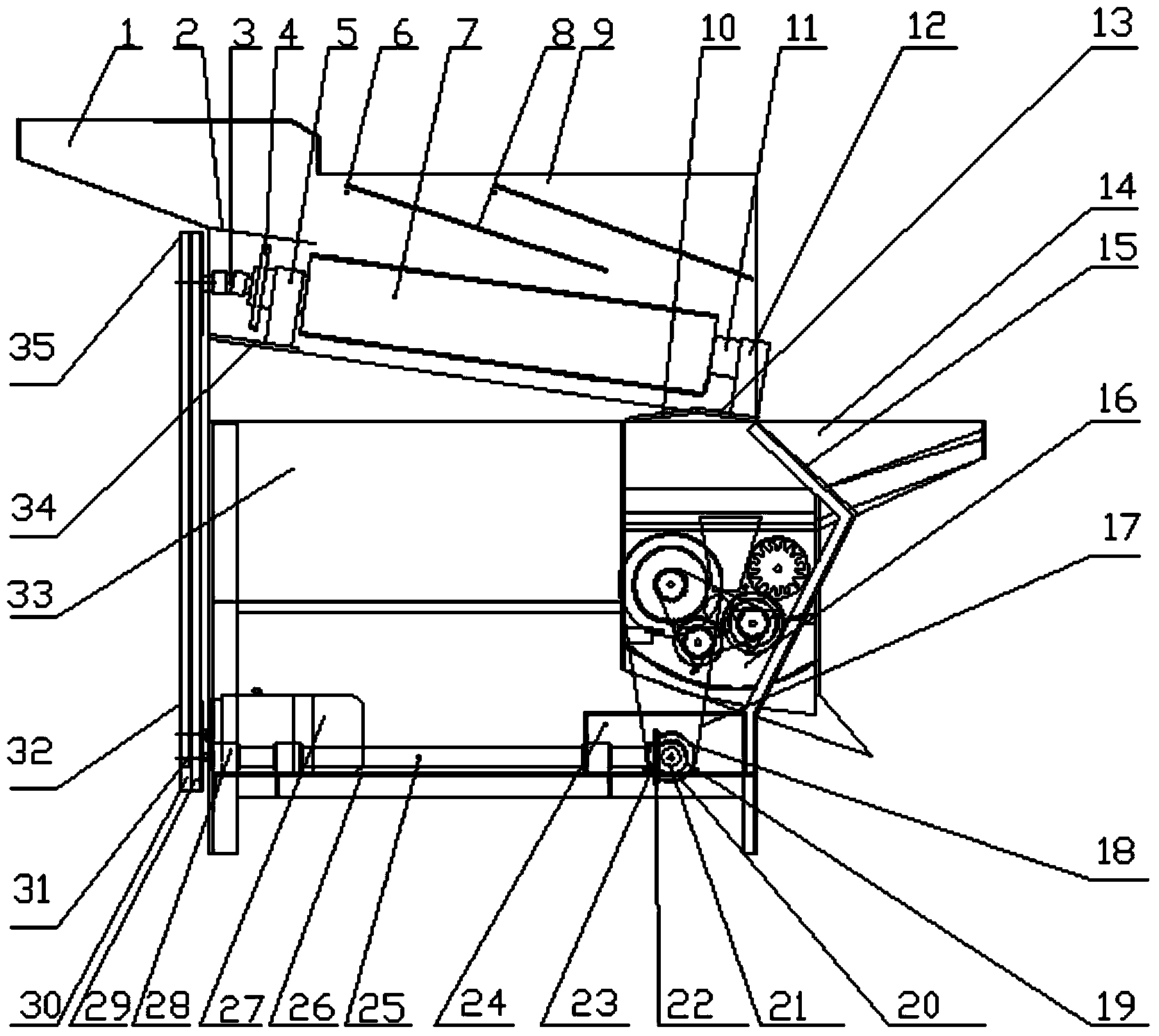

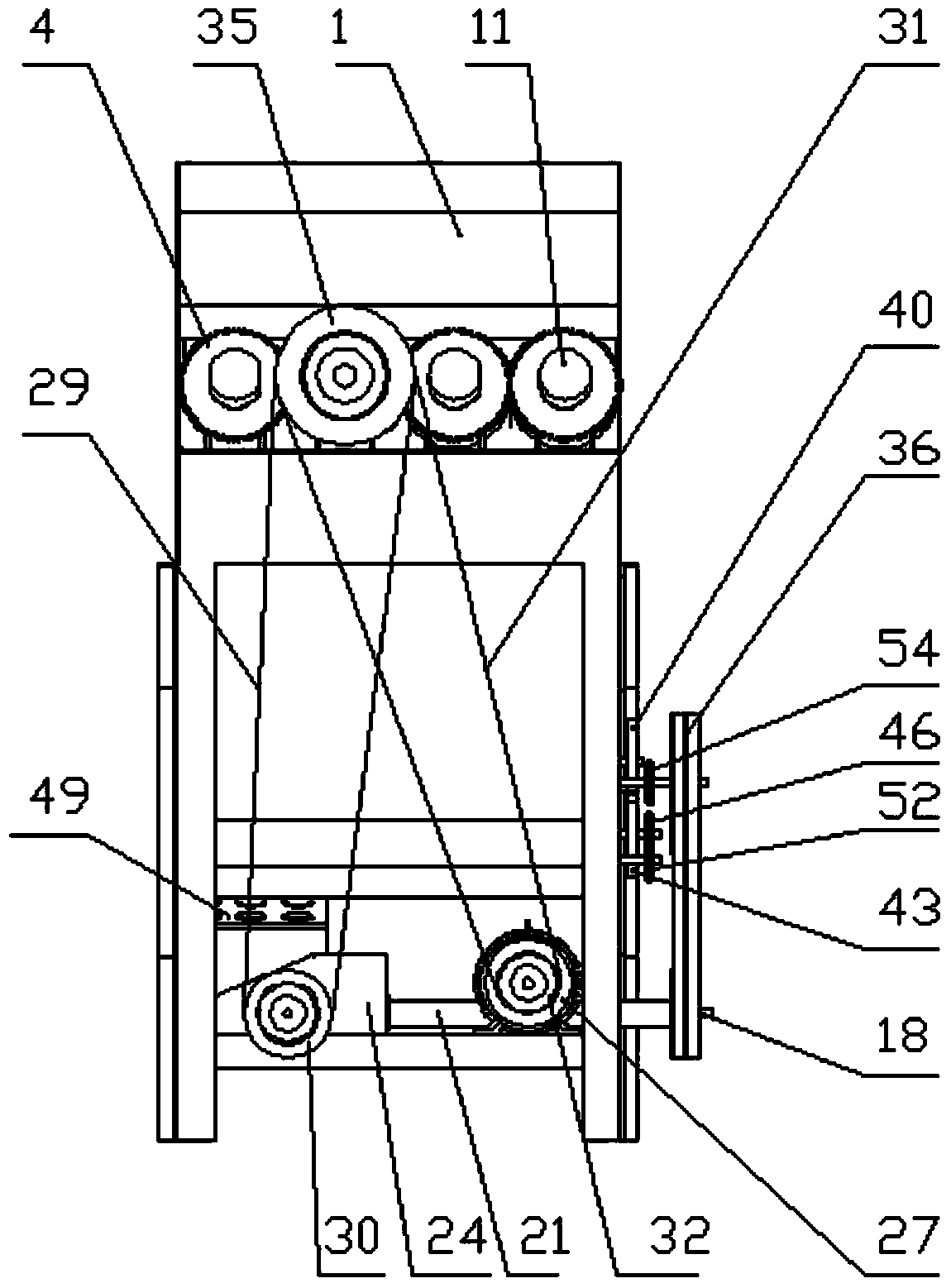

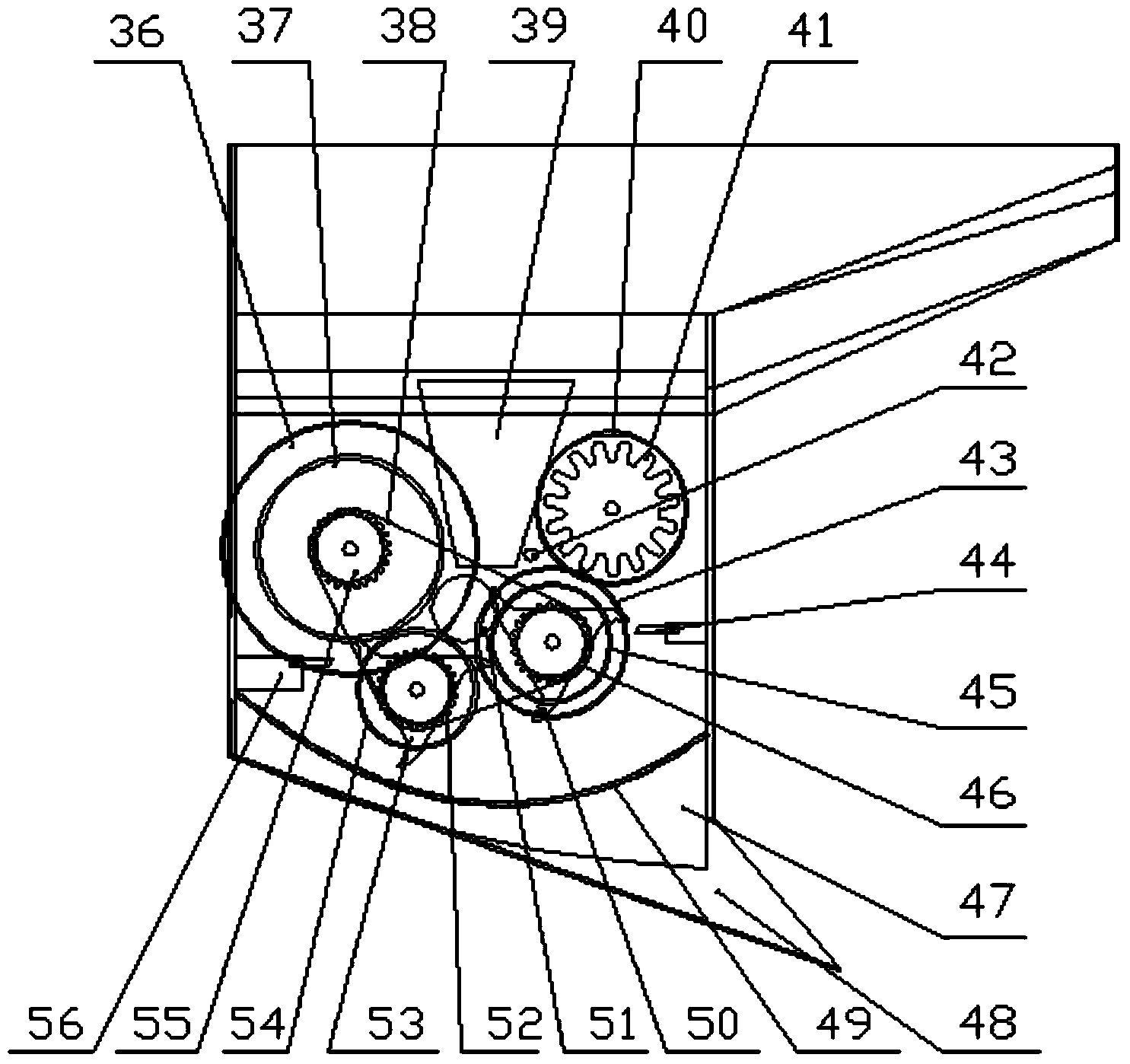

[0022] See attached picture, see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 with Figure 8 Shown is a small-sized fully automatic corn peeling, threshing and cob breaking machine, which includes a corn peeling part, a corn threshing part, a corn cob part and a power transmission part.

[0023] Two sets of inclined peeling rollers are installed on the frame of the corn peeling part. The periphery of the peeling roller group is provided with a coaming plate fixed on the frame. The peeling feed inlet 1 is provided with a corn threshing feed inlet 14 on the coaming plate at the lower end of the inclined peeling roller group. The peeling roller group includes successively adjacent first peeling roller A and second peeling roller B, The outer peripheral surfaces of the first peeling roller A and the second peeling roller B are in contact with each other and their rotation direction is the contact line of the steering roller from the top of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com