Bone screw

A bone screw and thread technology, applied in the field of medical devices, can solve the problems of large thread extrusion load, high screwing torque, and low quality of screw holes, and achieve high thread quality, reduce extrusion load, and reduce the risk of infection Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The idea, specific structure and technical effects of the present invention will be further described below in conjunction with the accompanying drawings, so as to fully understand the purpose, features and effects of the present invention.

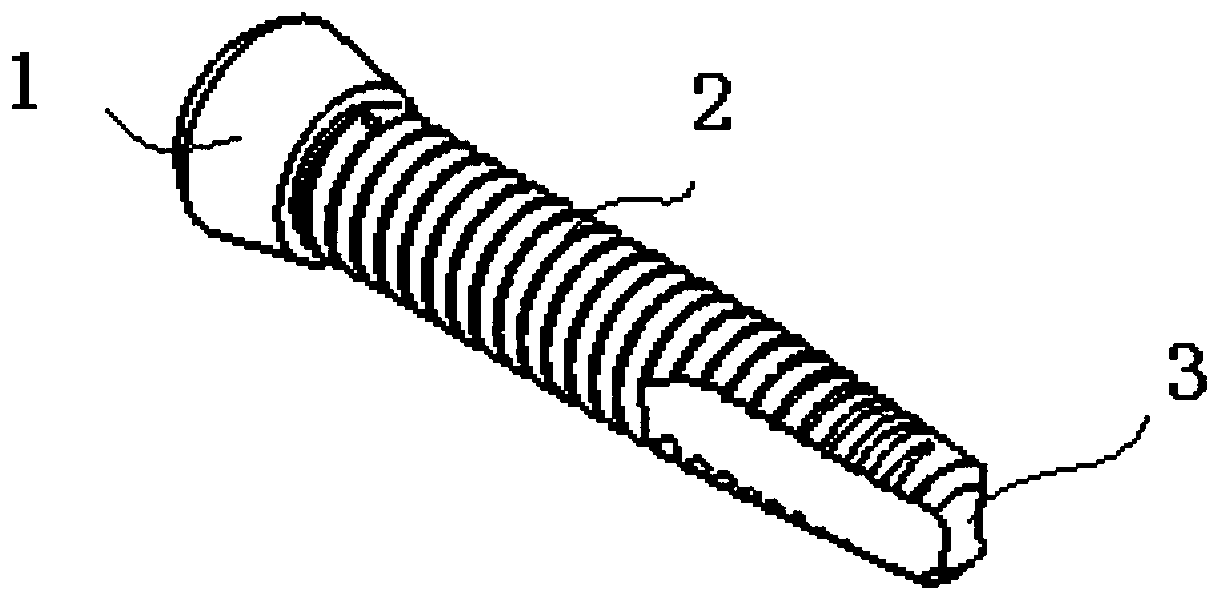

[0032] Such as figure 1 As shown, the bone screw of the present invention consists of three parts: a head 1 , a stem 2 and an end 3 . The end mainly has a pointed end and a flat end. However, according to the function of use, grooves, grooves, incisions or drill-like parts with cutting functions can be processed.

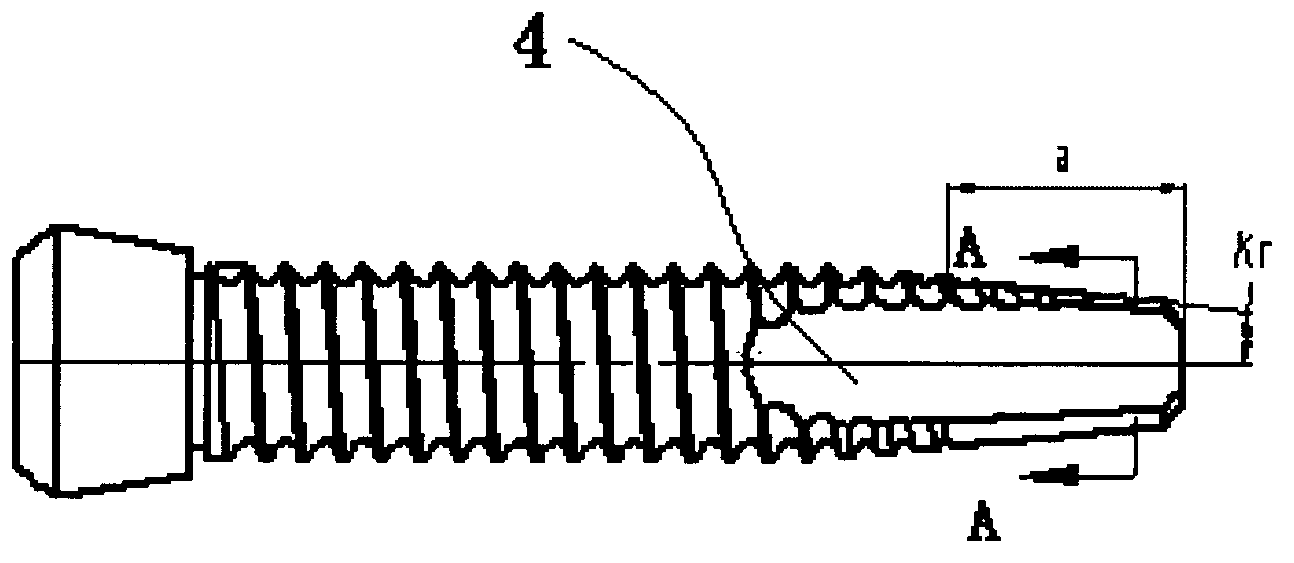

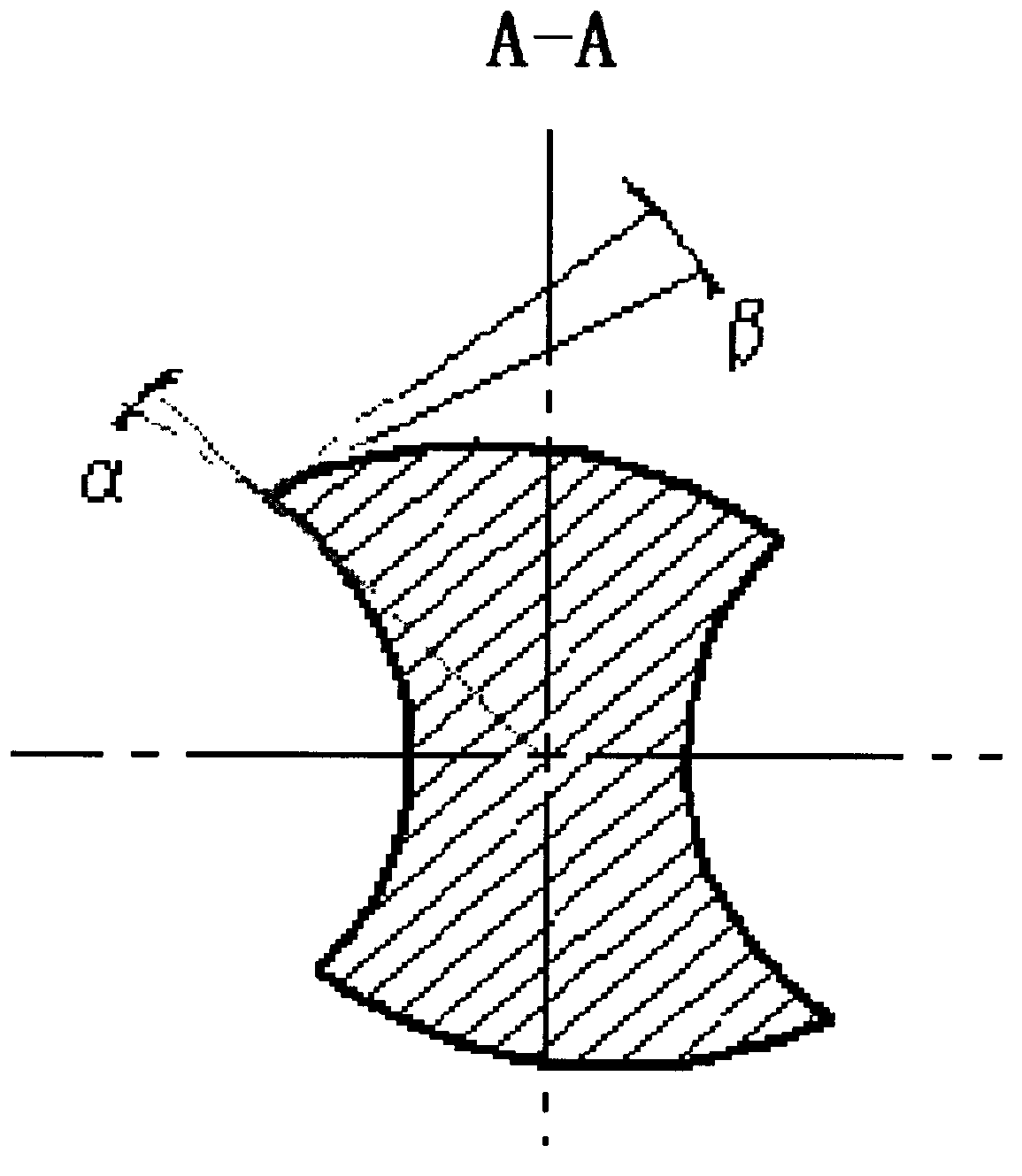

[0033] In the first preferred embodiment of the present invention, as figure 2 As shown, the end of the rod is a flat end, and the thread at the end of the bone screw has a cutting cone. The parameters of the cutting cone (groove shape, rake angle, and back angle) can refer to the tap, which is equivalent to the first few teeth of the bone screw in the inner hole. Tapping the thread reduces the extrusion load of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com