Solid-phase microextraction probe, and preparation method and application thereof

A probe and extraction technology, applied in the field of solid-phase microextraction probe and its preparation, can solve the problems of small acid-base range, insufficient use temperature, high analysis cost, etc., achieve high recovery rate, good linear range, detection low limit effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Preparation of carbon nanospheres: The carbon nanospheres are synthesized according to the literature (Sci Rep. 2013, 3, 1430), and the synthesis method is as follows:

[0038] (1) Synthesis of monodisperse polystyrene nanospheres: In a three-necked flask, 25 mg sodium dodecylsulfonate was dissolved in 100 mL ultrapure water, stirred for 15 min, and then filled with nitrogen in the three-necked flask . Then, 2.5 mL and 0.25 mL of divinylbenzene were added into the three-necked flask, and after stirring for 5 min, 100 mg of potassium persulfate was added, kept at 75 °C for 3 h, and then 0.25 mL of divinylbenzene was added for 24 h. Finally, the samples were washed with ethanol and dried under vacuum at 50 °C.

[0039] (2) Synthesis of microporous monodisperse polystyrene nanospheres: 1.0 g monodisperse polystyrene nanospheres synthesized above were dissolved in 30 mL tetrachloromethane, 2.8 g aluminum chloride was dissolved in 30 mL tetrachloromethane , the two solutio...

Embodiment 2

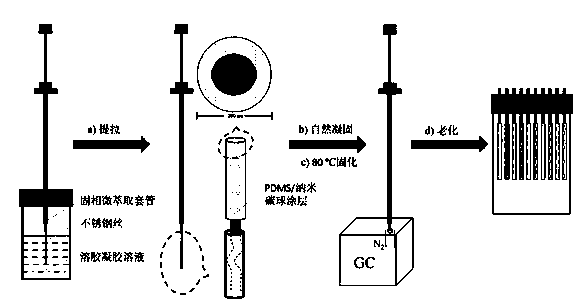

[0043] The preparation of carbon nanosphere / PDMS solid-phase microextraction probe, the preparation process is as follows figure 1 , including the following steps:

[0044] S1. Preparation of sol-gel solution: Weigh 5 mg carbon nanospheres, add 300 μL methyltrimethoxysilane, 20 μL ultrapure water, 20 mg polymethylsiloxane (PDMS), and sonicate for 30 min , and then add 20 μL of trifluoroacetic acid, sonicate for 10 min, observe the viscous state of the sol-gel solution, and let it stand for 10 min before use.

[0045] S2. Pretreatment of stainless steel fibers: cut the stainless steel fibers to a length of 3 cm, soak in acetone for 1 h, soak in 1 mol / L NaOH solution for 2 h, and soak in 0.1 mol / L hydrochloric acid soak in the solution for 2 h, and finally soak in ultrapure water for 1 h. Remove the stainless steel fiber from the ultrapure water and let it dry naturally.

[0046] S3. When the sol-gel solution described in S1 is in a viscous state, insert the stainless steel f...

Embodiment 3

[0050] The preparation of carbon nanosphere / PDMS solid-phase microextraction probe specifically comprises the following steps:

[0051] S1. Preparation of sol-gel solution: Weigh 15 mg carbon nanospheres, add 400 μL methyltrimethoxysilane, 50 μL ultrapure water, 50 mg polymethylsiloxane (PDMS), and sonicate for 30 min , and then add 50 μL of trifluoroacetic acid, sonicate for 10 min, observe the viscous state of the sol-gel solution, and let it stand for 20 min before use.

[0052] S2. Pretreatment of stainless steel fibers: cut the stainless steel fibers to a length of 3 cm, soak in acetone for 1 h, soak in 1 mol / L NaOH solution for 2 h, and soak in 0.1 mol / L hydrochloric acid soak in the solution for 2 h, and finally soak in ultrapure water for 1 h. Remove the stainless steel fiber from the ultrapure water and let it dry naturally.

[0053] S3. When the sol-gel solution described in S1 is in a viscous state, insert the stainless steel fiber treated in S2 into the sol-gel s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap