Titanium or titanium alloy golf ball head part forging method

A golf head and titanium alloy technology, applied in metal processing equipment and other directions, can solve the problems of reduced mechanical properties, future problems in golf head quality, and inability to guarantee mechanical properties, so as to eliminate material strain hardening, save energy, and reduce deformation resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

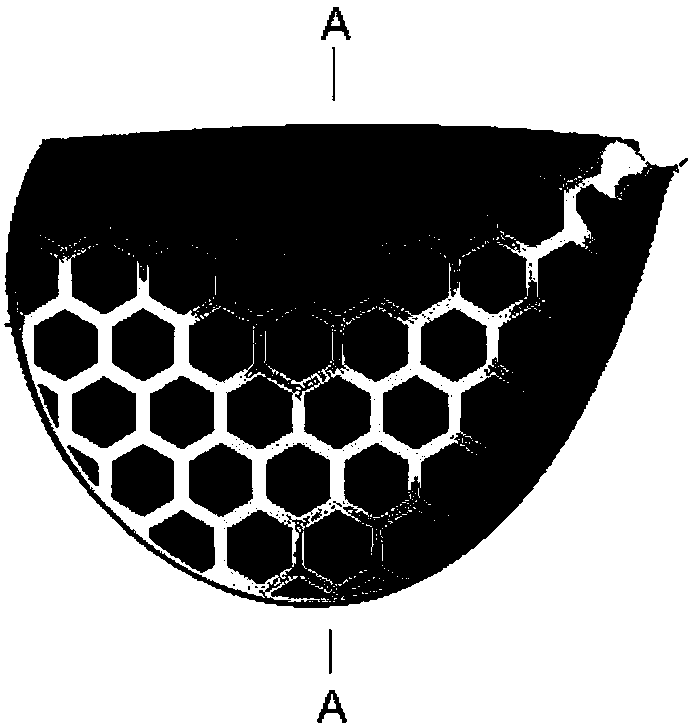

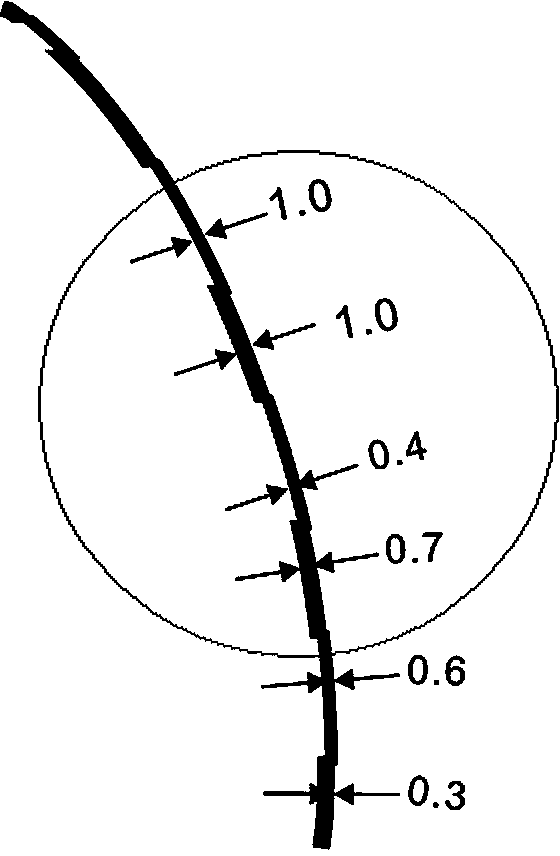

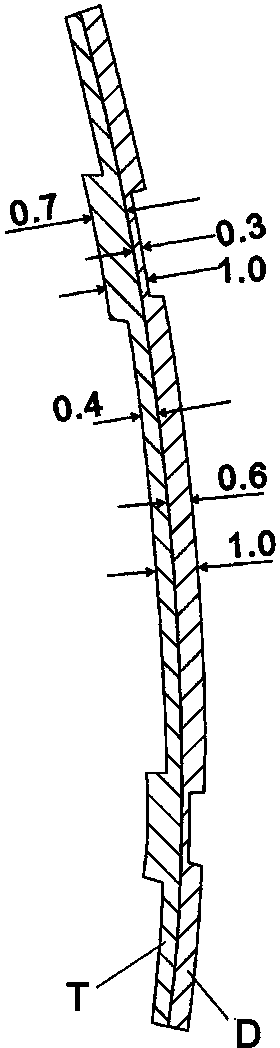

[0021] The titanium or titanium alloy golf head component forging method of the present invention, the forging workpiece including the golf head striking surface, upper cover or lower cover of titanium or titanium alloy material, together with the punch and die of the corresponding forging mold Put it in an electric heating furnace (the figure shows a forging piece with the upper cover of a golf head as an example), and place several forging workpieces on both sides of the forging mold in the furnace. After the furnace temperature is heated to the forging temperature (for example, the forging temperature of TC4α+β titanium alloy is 950°C, the forging temperature of TB9β titanium alloy is 730°C, etc.), directly place the forged workpiece on the convex / concave die of the forging mold in the furnace In between, the isothermal forging is carried out to the forged workpiece through the forging die still in the electric furnace with a pressure device. and figure 1 and figure 2 A ...

Embodiment 2

[0029] In this example, an induction coil connected to a power supply is used as an electric heating device for heating the forging workpiece and the forging die. Put the forged workpiece into the forging mold, heat it to the forging temperature with the induction coil together, and then use the pressure equipment to carry out the isothermal forging forming on the forged workpiece through the forging mold. Although this method can also solve the existing problems in the current forging of titanium or titanium alloy golf head parts, it is still inferior to Embodiment 1 in terms of energy consumption and production efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com