Crankshaft restoring method

A repair method and crankshaft technology, applied in the direction of the crankshaft, etc., can solve the problems of difficult to control welding quality, inability to process, not durable, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

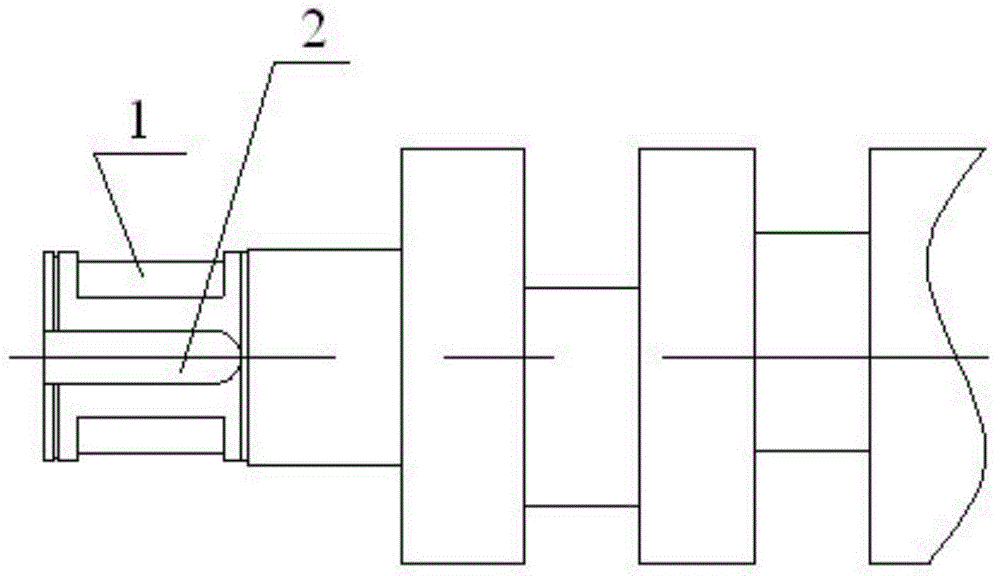

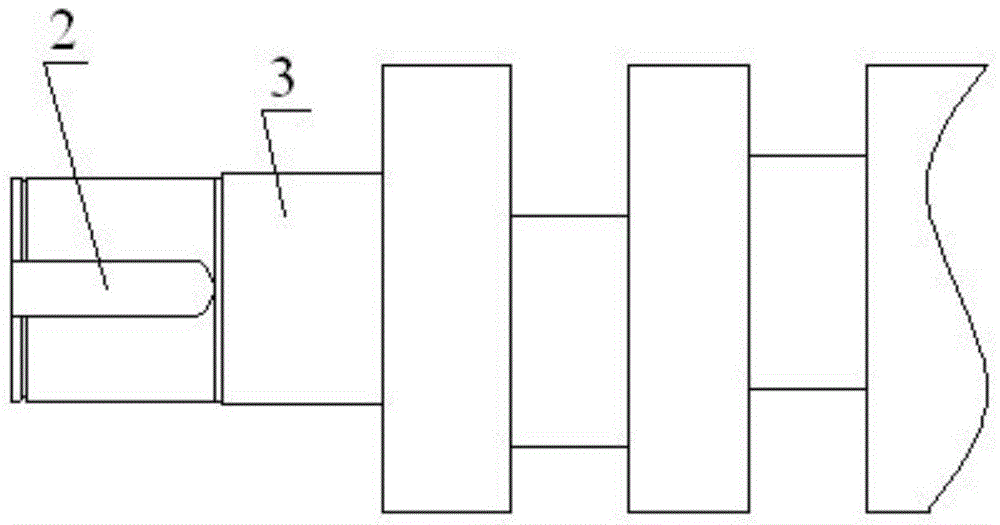

[0030] figure 1 It is a schematic diagram of the spline shaft before being repaired by a crankshaft repair method disclosed in the present invention. As shown in the figure, a crankshaft repair method of the present invention repairs the spline shaft. The repair steps are as follows:

[0031] (1) When milling the damaged part of the spline shaft, use a milling cutter to fix it, rotate the arc surface of the spline shaft, install a detachable rotating handle at the end of the spline shaft, and mill out the damaged part of the semicircular surface 1 of the spline shaft. Part of the semi-circular surface is arc groove-shaped, retaining the spring position of the spline shaft and the keyway 2; accurately grasping the arc surface of the shaft to be milled, controlling the damaged part of the shaft to be repaired, and avoiding the arc surface of the shaft to be milled by mistake. Wrong milling, improve accuracy;

[0032] (2) Support the bearing stands 3 at both ends of the spline s...

Embodiment 2

[0036] A crankshaft repair method of the present invention repairs the emulsification pump crankshaft, and the repair steps are as follows:

[0037] (1) When milling the damaged part of the crankshaft of the emulsification pump, fix it with a milling cutter, rotate the arc surface of the crankshaft of the emulsification pump, install a detachable rotating handle at the end of the crankshaft of the emulsification pump, mill out the partially damaged semicircular surface of the crankshaft of the emulsification pump, and mill out Part of the semicircular surface is in the shape of an arc groove, and the two sides of the keyway are reserved; accurately grasp the arc surface of the shaft to be milled, control the damaged part of the emulsification pump crankshaft, avoid the arc surface of the shaft to be milled by mistake or wrong milling, and improve Accuracy;

[0038] (2) Support the bearing platforms at both ends of the crankshaft of the emulsification pump and the middle part ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com