Variable pitch split type numeric control alignment system of paper laminating machine

A laminating machine and split-type technology, applied in the direction of pile separation, positioning objects, object supply, etc., can solve the problems of waste of power and human resources, waste of operating space, and reduced work efficiency, so as to improve production efficiency, simplify structure, The effect of enhancing market competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

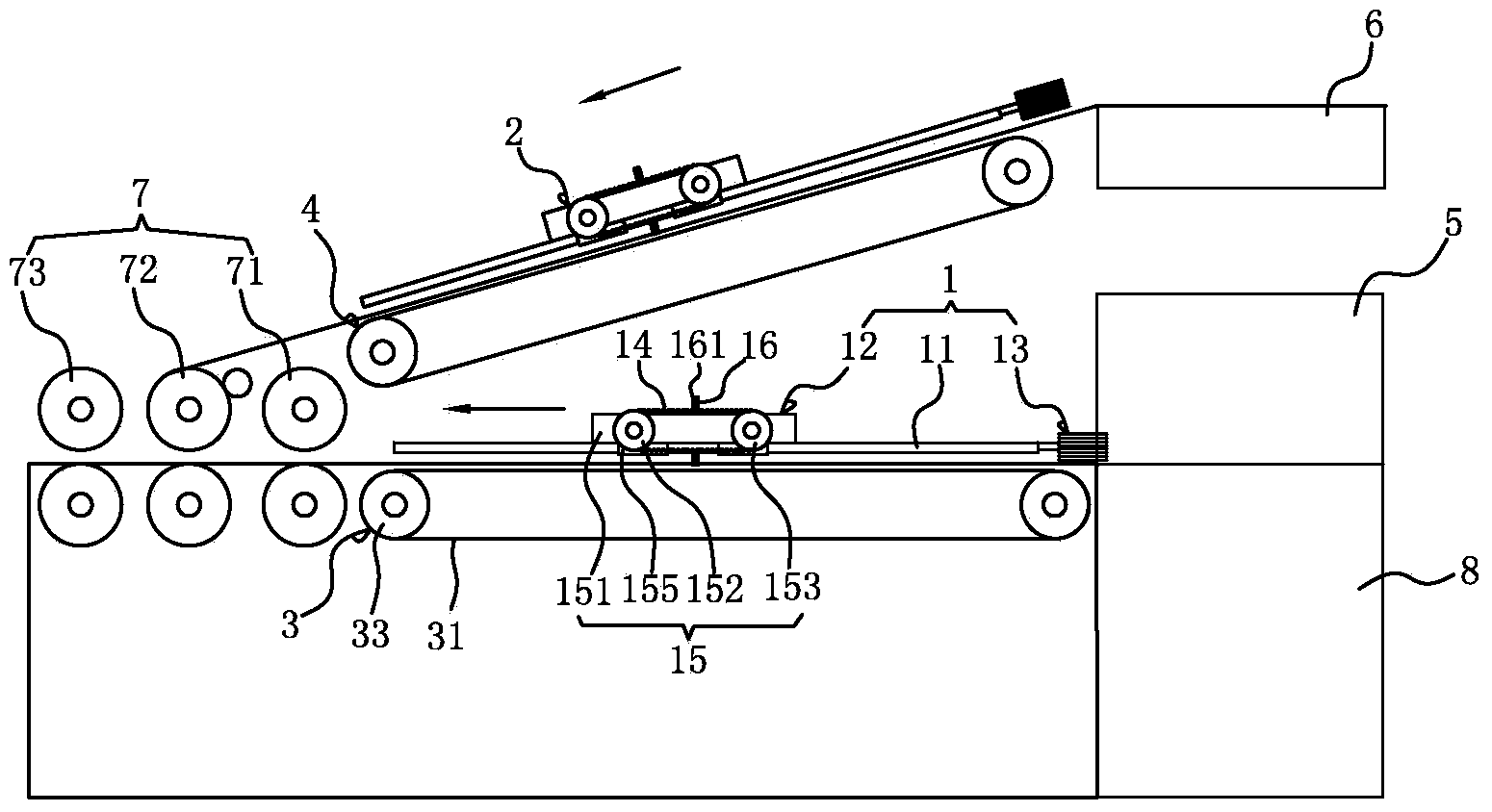

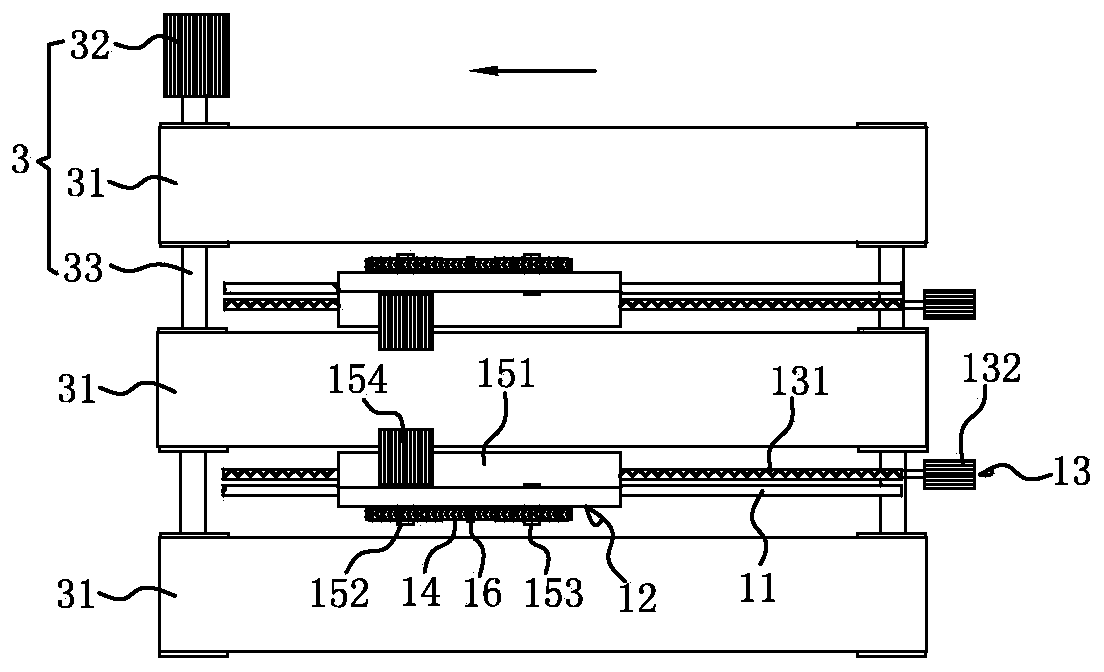

[0025] see figure 1 , 2 As shown, it is a kind of paper laminating machine, which includes: a frame 8, a first paper delivery mechanism 5 and a first conveying mechanism 3 that are installed on the frame 8 and are used to release and paste the base paper, and are used to release the stickers. The second paper release mechanism 6 and the second conveying mechanism 4 for the surface paper, the variable-distance split-type numerical control alignment system for simultaneously conveying and aligning the paper, and the installation on the first conveying mechanism 3 and the second conveying mechanism 4 The paper feeding wheel set and the coating and laminating wheel set device 7 at the rear end of the paper feeding stroke.

[0026] The first conveying mechanism 3 includes: at least three synchronous belts 31 that are distributed side by side and rotate synchronously, and a rotating member 32 that is installed on the frame 8 for the assembly of the synchronous belt 31 and a host mo...

Embodiment 2

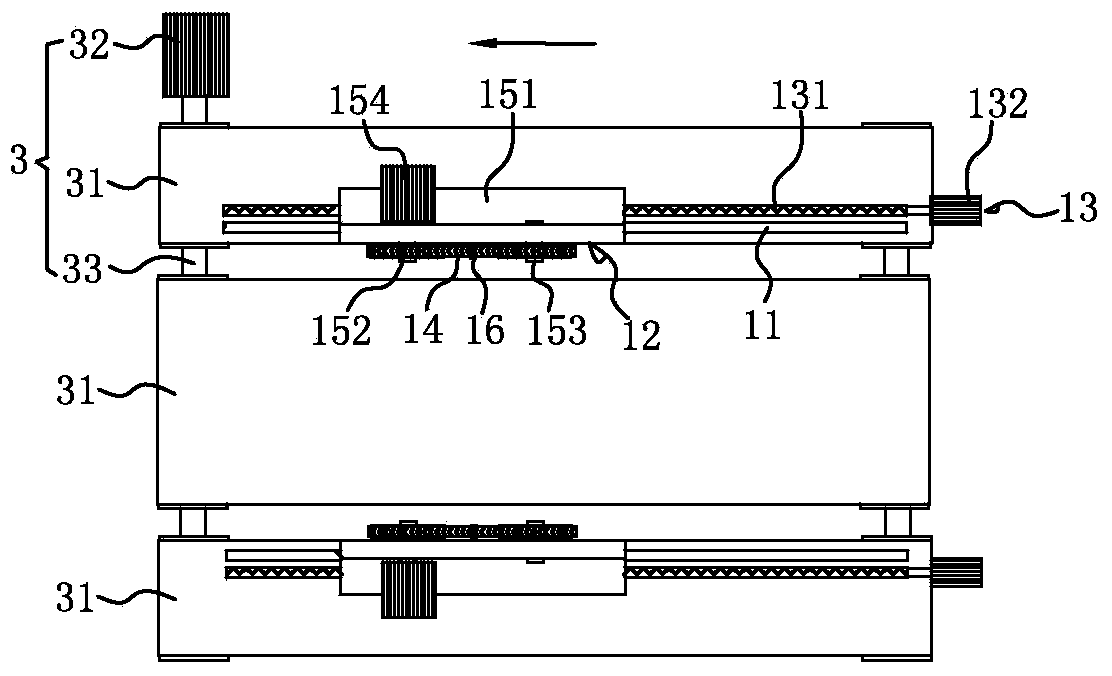

[0042] The basic structure of the second embodiment is the same as that of the first embodiment above, and the difference is that the size of the timing belt 31 in the middle position of the first conveying mechanism is increased, and the assembly position of the first alignment device is adjusted. see details image 3 shown, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com