A method of orienting carbon nanotubes by means of motion

A technology for orienting carbon nanotubes and carbon nanotubes, which is applied in nanotechnology, nanotechnology, nanostructure manufacturing, etc., can solve problems such as complex operations, high electric field strength, and increased difficulty in the orientation of carbon nanotubes, achieving a high degree of orientation , The effect of simple operation of orientation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Place a 75cm×500cm unidirectional glass fiber cloth soaked in epoxy resin on the workbench, and its width direction is the glass fiber direction.

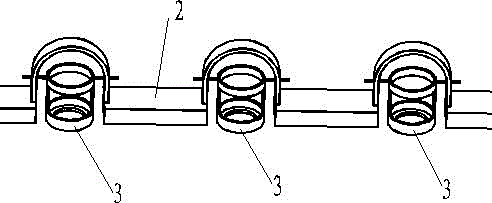

[0025] An iron support 2 is set above the surface of the glass fiber cloth, which consists of three U-shaped structures and four horizontal plates, such as figure 1 As shown, by means of welding or riveting, the four horizontal plates are fixedly connected to the three U-shaped structures respectively. Among them, the length of the two middle horizontal plates is 20cm, and the length of the two horizontal plates at both ends is 15cm. The distance between the two horizontal plates is 5 cm, and holes with a diameter of 0.3 cm are opened on both sides of the U-shaped structure. The fixture 3 of the ultrasonic spray head is fixed on its upper end, a cylinder with a diameter of 0.25cm and a length of 1cm, which is rotatably connected with the U-shaped structure. The upper part of the fixture 3 is a circle with a height of 8cm, an...

Embodiment 2

[0030] Place a 170cm×520cm copper plate on the workbench, place a 150cm×500cm unidirectional glass fiber cloth impregnated with phenolic resin in the center above the copper plate, and its width direction is the direction of the glass fiber.

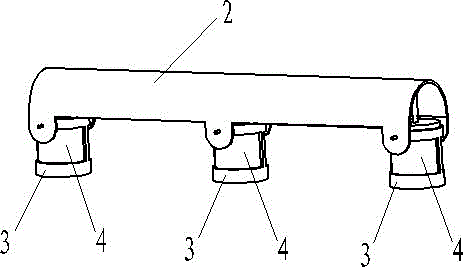

[0031] Iron support 2 is set above the glass fiber cloth surface, such as figure 2 As shown, it is a U-shaped structure with a length of 120 cm and a distance of 4.8 cm between the two side wings. On the side wings along the length direction of the support 2, a hole with a diameter of 0.3 cm is opened every 50 cm.

[0032] The structure of the fixing device 3 of the ultrasonic spray head is the same as that of the first embodiment, and is connected to the bracket 2 in a rotatable manner by fixing a cylinder with a diameter of 0.25 cm and a length of 1 cm fixed on its upper end.

[0033] The ZPQ-S-95 ultrasonic spray head is placed upside down in the fixing device 3. When it is vertically downward, the outlet position of the spray head i...

Embodiment 3

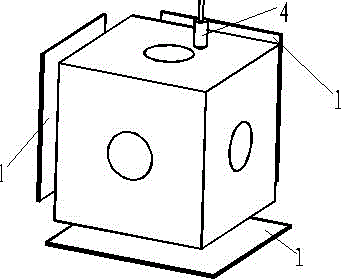

[0038] Such as image 3 As shown, a 30cm×30cm×30cm cube prepreg is placed on the worktable, and there are holes with a diameter of 5cm on the top surface and the center of the two sides, and 10cm×10cm are respectively placed on the outside 2cm of the surface with holes. copper plate.

[0039] The DPQ-T-95 ultrasonic spray head is installed on the M-10iAe spraying robot, and the storage tank connected with the spray head contains single-walled carbon nanotubes with an outer diameter of 3 nm and a length of 12 μm uniformly dispersed in chloroform. The weight content is 0.1%.

[0040] Connect the positive pole of the power supply with a voltage of 1.2 kV to the spray head, and the negative pole to the bottom copper plate, set the flow rate of the metering liquid pump to 2ml / min, start the metering liquid pump, and turn on the air pump, and set its pressure to 0.1MPa. Then start the robot, make the spray head take the hole center of the top face as the center, and make a circula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com