Method for synthesizing highly-oriented MFI (Melt Flow Index) molecular sieve membrane through controlled secondary growth of twin crystal

A secondary growth and orientation technology, applied in molecular sieves and alkali exchange compounds, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of cumbersome steps, complicated operation steps, high preparation costs, etc., and achieve good orientation and film layer Continuous, easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

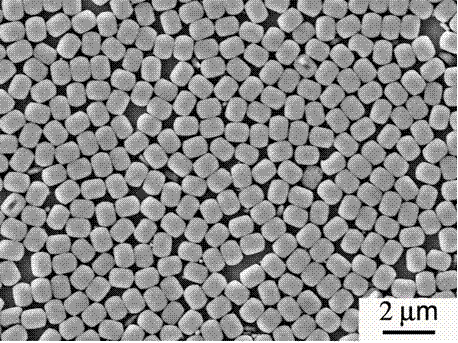

[0029] Apply the MFI type molecular sieve seed crystal powder to the surface of the smooth support, and then press and smooth it with a little force, that is, it is coated with b A support for the axis-oriented seed layer. Scanning electron microscope pictures of the seed layer as figure 1 shown.

Embodiment 2

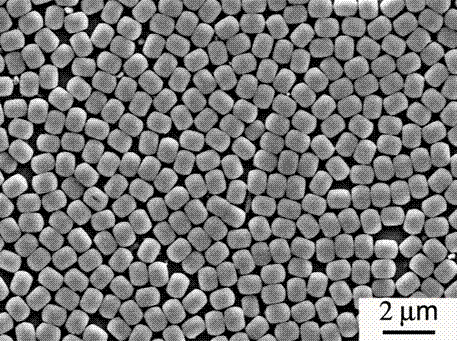

[0031] 40 milliliters of synthetic solution that the molar ratio is ethyl tetrasilicate: sodium hydroxide: water=1:0.20:165 was stirred at room temperature for 4 hours to obtain a clear and transparent solution, and then this synthetic solution was mixed with the coating prepared in Example 1 The support with the seed layer was placed together in a 100 ml synthesis kettle with a polytetrafluoroethylene liner, and then the sealed synthesis kettle was placed in a blast oven at 200°C for 10 minutes of crystallization, and finally the crystal The thawed synthesis kettle was taken out, and after quenching to room temperature, the support body was taken out, washed with deionized water, and then dried. The scanning electron microscope pictures of the dried molecular sieve membranes are as follows: figure 2 As shown, the obtained molecular sieve membrane is highly b Axially oriented MFI type molecular sieve membrane, but discontinuous.

Embodiment 3

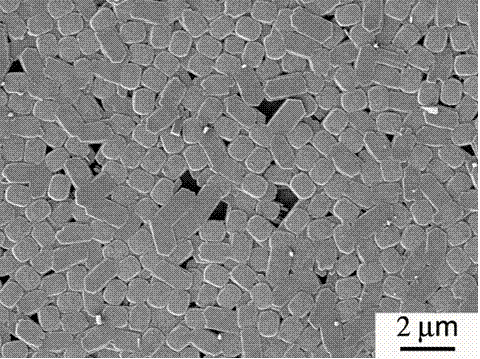

[0033] 40 milliliters of synthetic solution that molar ratio is tetrapropyl ammonium hydroxide: sodium hydroxide: water=1:0.001:0.10:165 is stirred at room temperature for 10 hours, obtains clear and transparent solution, then this The synthetic solution and the support coated with the seed layer prepared in Example 1 were put into a 100 ml synthesis kettle with a polytetrafluoroethylene liner, and then the sealed synthesis kettle was put into a blast oven at 150° C. The internal crystallization was carried out for 3 hours, and finally the synthesis kettle after crystallization was taken out, and the support body was taken out after quenching to room temperature, washed with deionized water, and then dried. The scanning electron microscope pictures of the dried molecular sieve membranes are as follows: image 3 As shown, the obtained molecular sieve membrane is highly b Axially oriented MFI type molecular sieve membrane.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com