Sheet solidification double-layer cooling device and double-layer cooling rack

A technology of cooling device and cooling rack, which is applied in the direction of transportation and packaging, mechanical conveyors, conveyors, etc., can solve the problems of large space occupation, long conveying distance, and increased production cost of artificial quartz plates, so as to reduce the occupied space Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

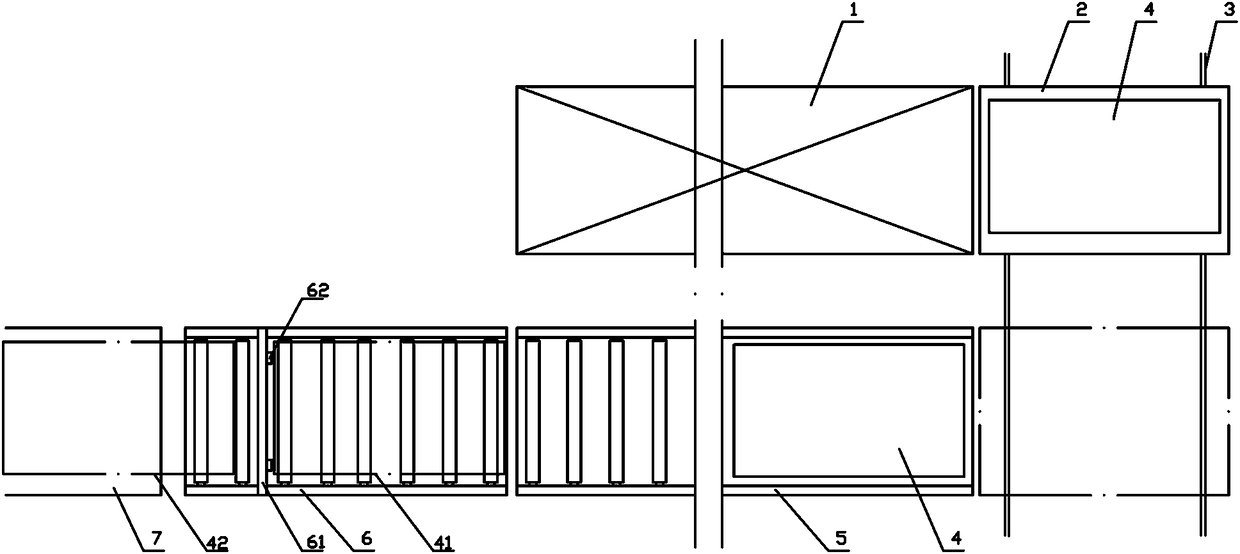

[0031] Such as figure 1 Among them, a plate solidification double-layer cooling device, including a drying device 1, is characterized in that the drying device 1 is connected to one end of the double-layer cooling rack 5 through a transfer vehicle 2, and the other end of the double-layer cooling rack 5 is connected to the bottom. The transition transfer frame 6 with lifting device is connected;

[0032] Described double-layer cooling frame 5 is provided with upper roller 53 and lower roller 54, and upper roller 53 and lower roller 54 are driven to rotate by different motors respectively;

[0033] The gap between the upper roller 53 and the lower roller 54 is at least enough to allow the plate 41 to pass through, and the transition transfer frame 6 is aligned with the upper roller 53 and the lower roller 54 respectively by lifting. The double-layer cooling frame 5 doubles the distance of the cooling section under the same occupied space condition by adopting the structure of t...

Embodiment 2

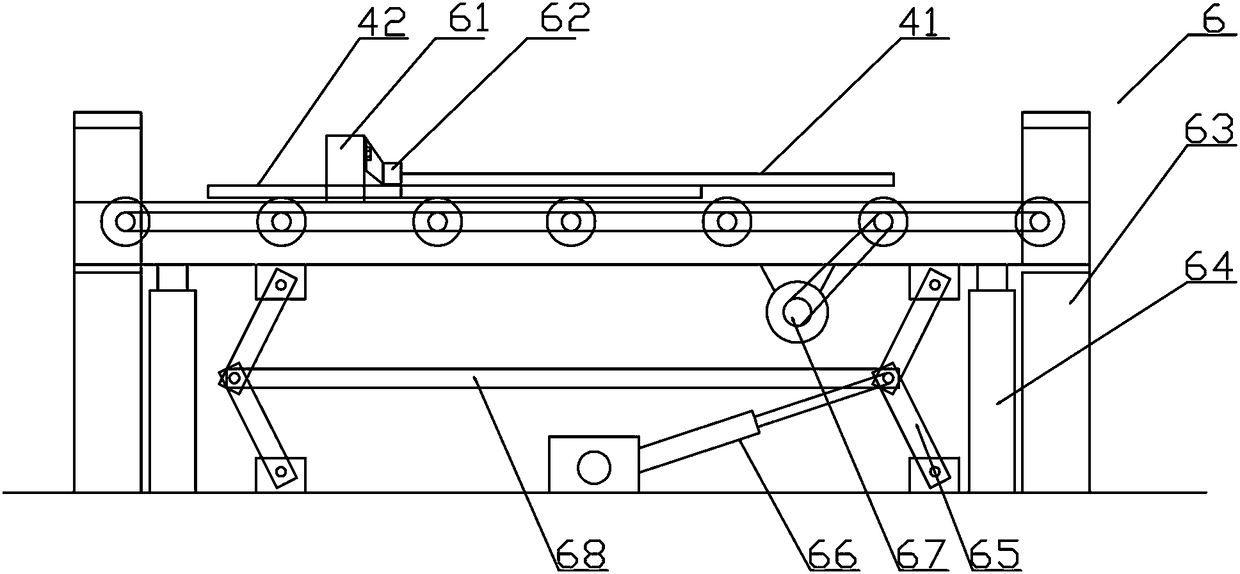

[0046] Such as Figure 1~3 A kind of double-layer cooling rack used for solidification and cooling of plates, the double-layer cooling rack 5 is provided with an upper roller 53 and a lower roller 54, and the upper roller 53 and the lower roller 54 are driven by different motors to rotate respectively; the upper roller 53 and the lower roller The gap between the rollers 54 is at least sufficient to allow the sheet material 41 to pass through.

[0047] One end of the double-layer cooling frame 5 is connected with the transitional transfer frame 6 provided with a lifting device at the bottom, and the transitional transfer frame 6 is aligned with the upper roller 53 and the lower roller 54 respectively by lifting. The plate and template 4 are transported from the upper roller 53 to the transition transfer frame 6, the template 42 is removed manually or automatically, then the transition transfer frame 6 is lowered and aligned with the lower roller 54, and then the plate 41 is tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com