High-efficiency and energy-saving rolled steel production device

A production equipment, high-efficiency and energy-saving technology, applied in the direction of keeping the roll equipment in an effective state, metal processing equipment, workpiece surface treatment equipment, etc. Lubrication effect, quality assurance, cooling efficiency improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

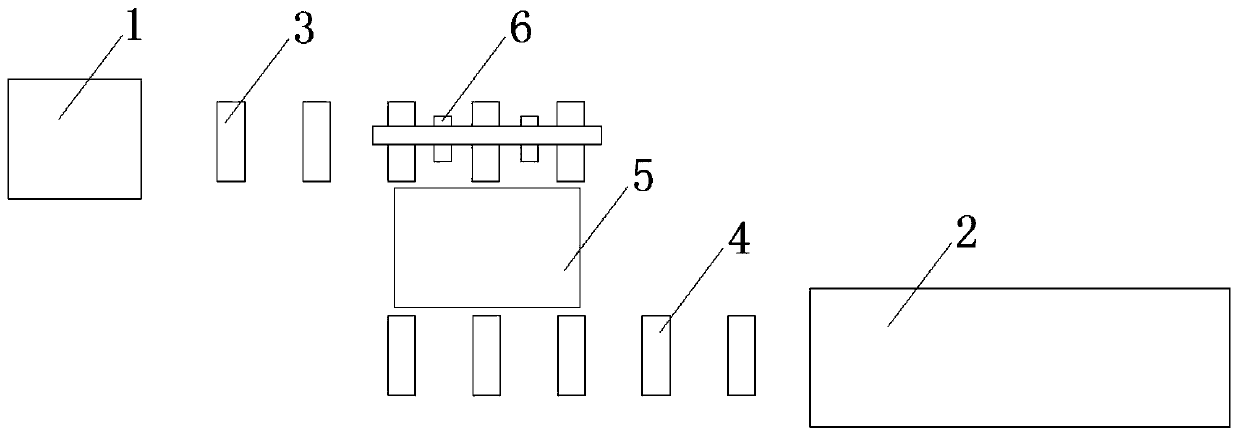

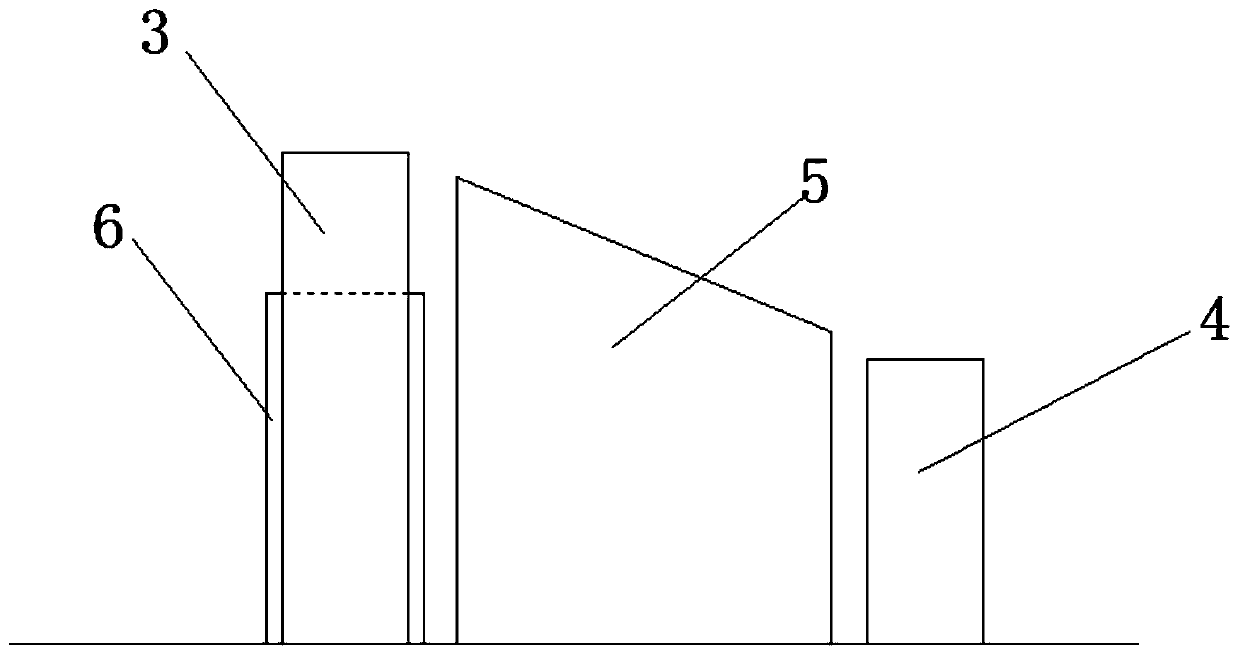

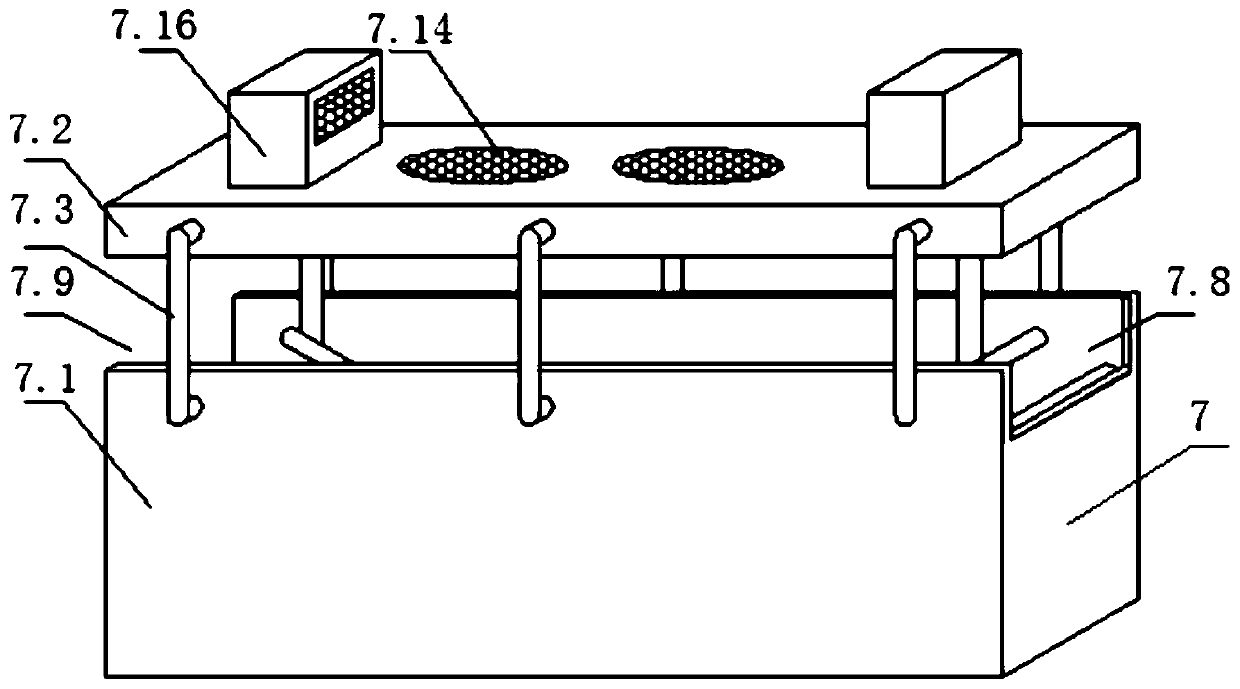

[0029] see Figure 1 to Figure 8 , the present invention relates to a high-efficiency and energy-saving steel rolling production equipment, the production equipment includes a heating furnace 1 and a rolling mill 2, a heating furnace discharge idler group 3 and a rolling mill feed idler are arranged between the heating furnace 1 and the rolling mill 2 Group 4, the heating furnace discharge idler group 3 communicates with the discharge port of the heating furnace 1, the rolling mill feed idler group 4 communicates with the feed port of the rolling mill 2, and the heating furnace discharge idler group 3 It is set horizontally parallel to the rolling mill feeding roller group 4, the top of the heating furnace discharging roller group 3 is higher than the rolling mill feeding roller group 4 top, the heating furnace discharging roller group 3 and the rolling mill feeding roller group 4 pass through a The inclined roller table 5 is connected to each other, and the inclined roller ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com