Solar cell assembly frame and angle assembling device and process thereof

A technology of solar cells and angle assembly, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of unstable riveting angle quality, high labor intensity, high maintenance cost, etc., achieve overall product consistency control, improve work and The effect of production efficiency and accurate positioning reference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

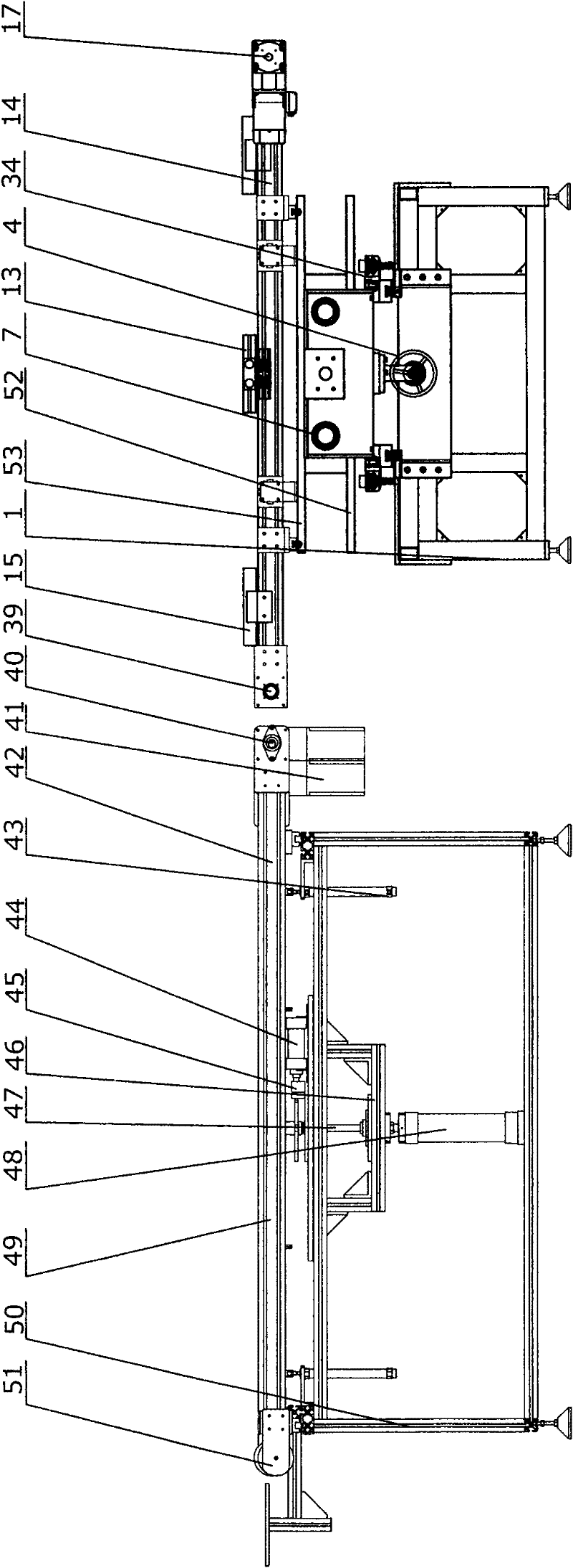

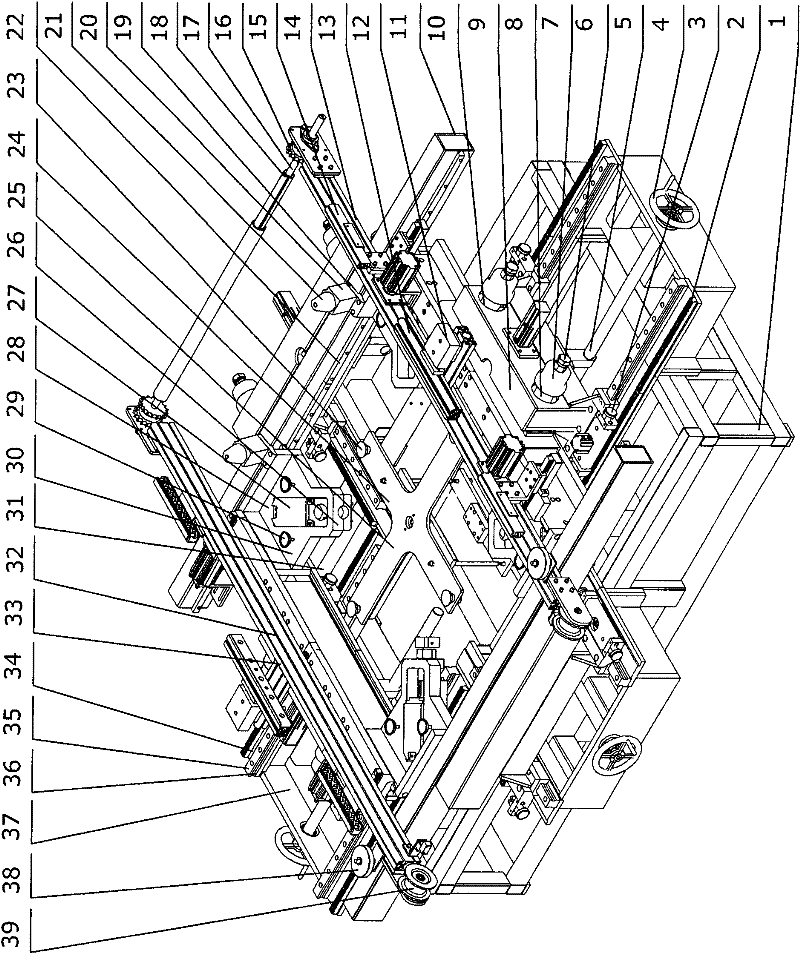

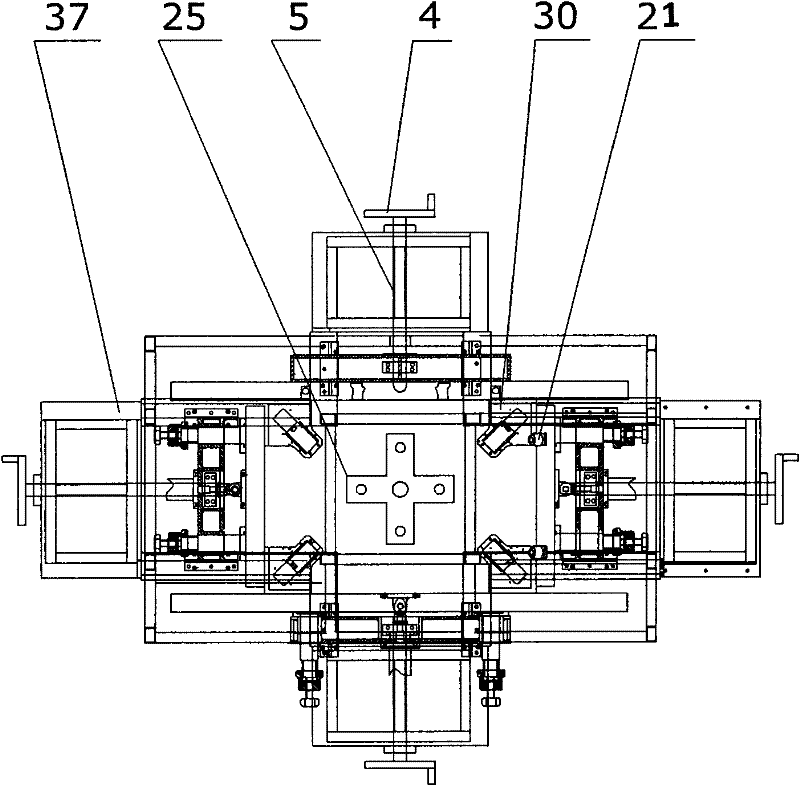

[0026] The present invention comprises frame 1, and the center of frame 1 is provided with elevating mechanism 25, and pallet 24 on elevating mechanism 25 is successively connected with upper cylinder 63, lower cylinder 61 through output shaft, and upper cylinder 63 is fixed by guide support plate 65, and lower Cylinder 61 is fixed between support plate 62 and frame 1, and vacuum suction cup 23 is arranged on pallet 24; The movable support 9 is respectively provided with a group frame crossbeam 11 connecting the upper guide plate 53 and the lower guide plate 52, and the lower guide plate 52 fixes the group corner bottom plate 31 of the group corner oil cylinder 26 to be connected with the group frame crossbeam 11 and fixed in the frame 1 The group angle base plate 31 on the peripheral angle is provided with a group angle mechanism 30, and the top of the group angle mechanism 30 is provided with an oblique support 19 connecting the bevel wheel 21 with the cylinder 20; On the mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com