Method for production of bullion lead by two-section smelting processing on lead anode slime

A technology of lead anode slime and precious lead, which is applied in the field of precious metal pyrometallurgy and two-stage smelting treatment of lead anode slime to produce noble lead, which can solve the problems of long production cycle, low processing capacity of smelting furnace, and large consumption of reducing agent. Reach the effect of reducing fuel consumption, fuel consumption is obvious, and fuel consumption is reduced

Active Publication Date: 2014-05-28

YUNNAN CHIHONG ZINC & GERMANIUM

View PDF5 Cites 11 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0008] From the above invention patents, it can be seen that the treatment of lead anode slime is basically using a smelting furnace at 900-1000°C or 1000-1200°C or 1200-1300°C Under high temperature conditions, noble lead can be obtained by reduction smelting, which has the following process defects: 1) Anode slime and reducing agent are added together. During the smelting process, arsenic and antimony that have been naturally oxidized are reduced into noble lead, and the consumption of reducing agent is large. The yield of noble lead produced is high, the grade of noble lead containing Ag is low, the amount of noble lead processed in the later stage is large, the refining cycle is long, and the amount of slag produced is also large, and the probability of mechanical entrainment of silver during slag discharge is high; 2) anode slime and When the flux is mixed and added, the As, Sb oxide, lead oxide and soda ash in the lead anode slime form high-alkali slag earlier, covering the surface of the melt, hindering the volatilization of As and Sb, resulting in low volatilization rates of As and Sb, and the consumption of soda ash as a flux A large amount of slag containing high arsenic and antimony is produced, which is not conducive to the recovery of arsenic and antimony; 3) The direct reduction smelting temperature is relatively high, and the consumption of fuel, reducing agent and flux is large, which directly leads to high production costs; 4) Direct reduction smelting Reduction smelting process, the production cycle is relatively long, and the processing capacity of the smelting furnace is low

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

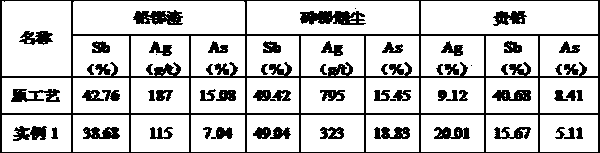

Embodiment 1

example 1

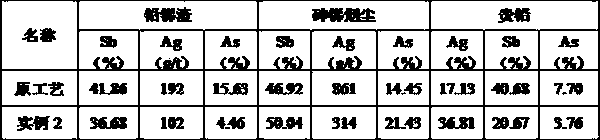

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to a method for production of bullion lead by two-section smelting processing on lead anode slime, and belongs to a noble metal pyrometallurgical technology. The method improves the traditional technology that bullion lead is produced by processing the lead anode slime in a pyrometallurgical-process reducing smelting way. In comparison with an existing traditional technology for production of bullion lead by lead anode slime, the method has the advantages as follows: in the same converter, the technology includes two processes of low-temperature oxidation and high-temperature retailoring, the auxiliary material adding and charging method is changed into that after the lead anode slime is subjected to complete oxidation and converting, a reducing agent and a fluxing agent are further added for retailoring. Therefore, the method greatly reduces the adding amounts of anthracite coal as the reducing agent and soda ash as the fluxing agent, and lowers fuel consumption, the efficiency of arsenic and antimony removal is high, high-grade bullion lead is obtained, and the production capacity of the original converter is increased by 50%.

Description

technical field The invention relates to a two-stage smelting method for producing noble lead from lead anode slime, which belongs to the noble metal pyrometallurgical technology, specifically the noble metal pyrometallurgical technology. Background technique There are basically two methods for the treatment of lead anode slime: fire process and wet process. The wet production process is long, the cycle is long, the production cost is high, and the amount of wastewater treatment is large; the treatment of lead anode slime at home and abroad generally adopts the traditional pyrotechnic process. The process principle is to mix lead anode slime, reducing agent, and solvent into the smelting furnace to reduce and smelt to produce precious lead, and then oxidize and refine the precious lead to produce gold-silver alloy with a purity greater than 97%. There are many researches on the treatment methods of lead anode slime in China: The title of the invention "A Method for Treati...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C22B7/00C22B13/02

CPCY02P10/20

Inventor 张梅邓远久李雪松丁旭李宗兴余秋雁闫建英袁明建裴启飞张小丽刘德国陈学斌杨华

Owner YUNNAN CHIHONG ZINC & GERMANIUM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com