A two-stage smelting method for producing precious lead from lead anode slime

The technology of lead anode slime and precious lead is applied in the field of precious metal pyrometallurgy, two-stage smelting treatment of lead anode slime to produce precious lead, and can solve the problems of long production cycle, low processing capacity of smelting furnace and large consumption of reducing agent, etc. Achieve the effect of decreasing fuel consumption, obvious fuel consumption and reducing fuel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Example 1: Add 10t of lead anode slime whose raw material composition is Ag5.12%, Au13.79g / t, Pb18.7%, Sb36.13%, As10.37%, Bi5.67%, Cu3.48% into noble lead converter , turn on medium and small fire, slowly raise the temperature, control the melting temperature at 600-700°C, turn the furnace once every half an hour to accelerate the melting of materials, and blow compressed air into the molten pool for 1.5-2 hours to make arsenic, antimony and The form of arsenic trioxide and antimony trioxide enters the flue gas. After the flue gas volatilizes for 3.5 to 4 hours, stop the blast, add 60kg of anthracite and 210kg of soda ash as auxiliary materials, blow and stir to completely melt them, stop the blast, and raise the furnace temperature to 900-1000°C, after 1-1.5 hours of static precipitation, the slag is released, the temperature is lowered to produce noble lead, and the production cycle is 8-9 hours.

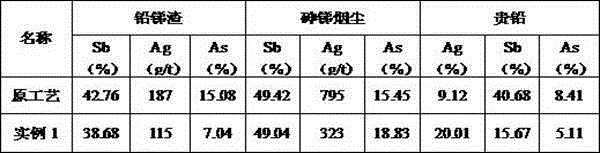

[0025] The results are shown in Table 1 and Table 2:

[0026] ...

Embodiment 2

[0029] Example 2 : Add 10t of lead anode slime whose raw material composition is Ag10.13%, Au14.45g / t, Pb10.4%, Sb36.09%, As10.45%, Bi6.55%, Cu3.16% to noble lead converter Inside, turn on the medium and small fire, slowly raise the temperature, control the melting temperature at 600-700°C, rotate the furnace every half an hour to speed up the melting of the material, after 1.5-2 hours of melting, blow compressed air into the molten pool to make the arsenic, Antimony enters the flue gas in the form of arsenic trioxide and antimony trioxide. After the flue gas volatilizes for 3.5 to 4 hours, stop the blast, add 50kg of anthracite and 200kg of soda ash as auxiliary materials, blow and stir to completely melt them, stop the blast, and lower the furnace temperature Raise the temperature to 900-1000°C, let it settle for 1-1.5 hours, discharge the slag, cool down to produce noble lead, and the production cycle is 7-8 hours.

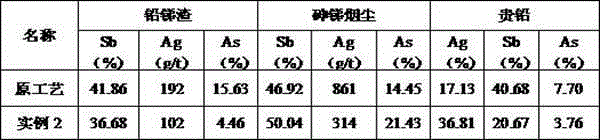

[0030] The results are shown in Table 3 and Table 4:

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com