Aluminum electrolysis plastidome for aluminum oxide electrolysis of one-step acid solution method production and application of aluminum electrolysis plastidome

A technology of aluminum electrolyte and alumina, which is applied in the field of alumina electrolyte, can solve problems such as the inability to apply alumina, achieve good solubility, improve current efficiency, and solve the effects of insufficient supply

Active Publication Date: 2014-05-28

CHINA SHENHUA ENERGY CO LTD +1

View PDF4 Cites 8 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, compared with the alumina products produced by the traditional Bayer method, sintering method or combined method, the alumina obtained by one-step acid-dissolving method has larger bulk density, particle size, angle of repose (fluidity), specific surface area, etc. The difference makes it impossible to apply the electrolyte system used in the production of alumina by the traditional alkaline method to the electrolysis of alumina obtained by one-step acid solution extraction.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

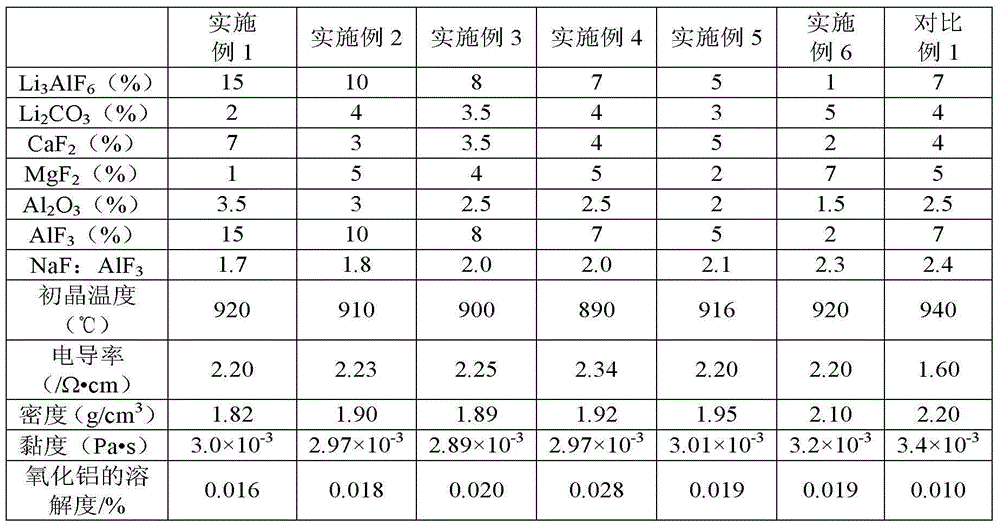

[0024] The aluminum electrolyte system was prepared by mixing the components in Table 1, and each raw material component was a commercially available product with high purity. Comparative example 1

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses an aluminum electrolysis plastidome for aluminum oxide electrolysis of one-step acid solution method production and an application of the aluminum electrolysis plastidome. The aluminum electrolysis plastidome comprises Na3AlF6, Al2O3 and an additive, wherein the additive comprises AlF3, Li2CO3, CaF2, MgF2 and Li3AlF6. The aluminum electrolysis plastidome is applied to an aluminum oxide electrolysis production process of the one-step acid solution method production; an electrolysis temperature lower than that of an electrolyte for the traditional alkaline aluminum oxide can be achieved; aluminum oxide produced by a one-step acid solution method has good solubility in the electrolyte, so that the current efficiency is improved; the purposes of energy conservation and emission reduction are better achieved; the problem of short supply of aluminum oxide domestically is solved; and a new efficient path is opened up for comprehensive utilization of pulverized fuel ash.

Description

technical field [0001] The invention relates to the technical field of alumina electrolytes, in particular to an aluminum electrolyte system for alumina electrolysis produced by a one-step acid dissolution method and its application. Background technique [0002] The electrolyte is the reaction medium for dissolving aluminum oxide and reducing it to metallic aluminum during aluminum electrolysis. Aluminum electrolysis cannot be carried out in aqueous solution, because only hydrogen can be precipitated on the cathode but not aluminum during electrolysis in aqueous solution. Therefore, it must The molten salt electrolyte is used, and the electrolyte is not only a solvent but also a medium conductor of electricity. Therefore, the industry has the following performance requirements for the electrolyte: first, it can dissolve alumina well and have high solubility; second, the electrolyte has good conductivity, which makes the resistivity of the electrolyte lower, which is benefic...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C25C3/18

Inventor 韩建国张一雯郭昭华张锋韩硕赵明池君洲王永旺

Owner CHINA SHENHUA ENERGY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com