Method for preventing rock burst through secondary pressure relief

A technology of rockburst and geological conditions, which is applied in surface mining, earthwork drilling, underground mining, etc., can solve the problems of high cost of large drilling, rockburst, and inability to construct, achieve low cost, prevent rockburst Increased, less risky effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

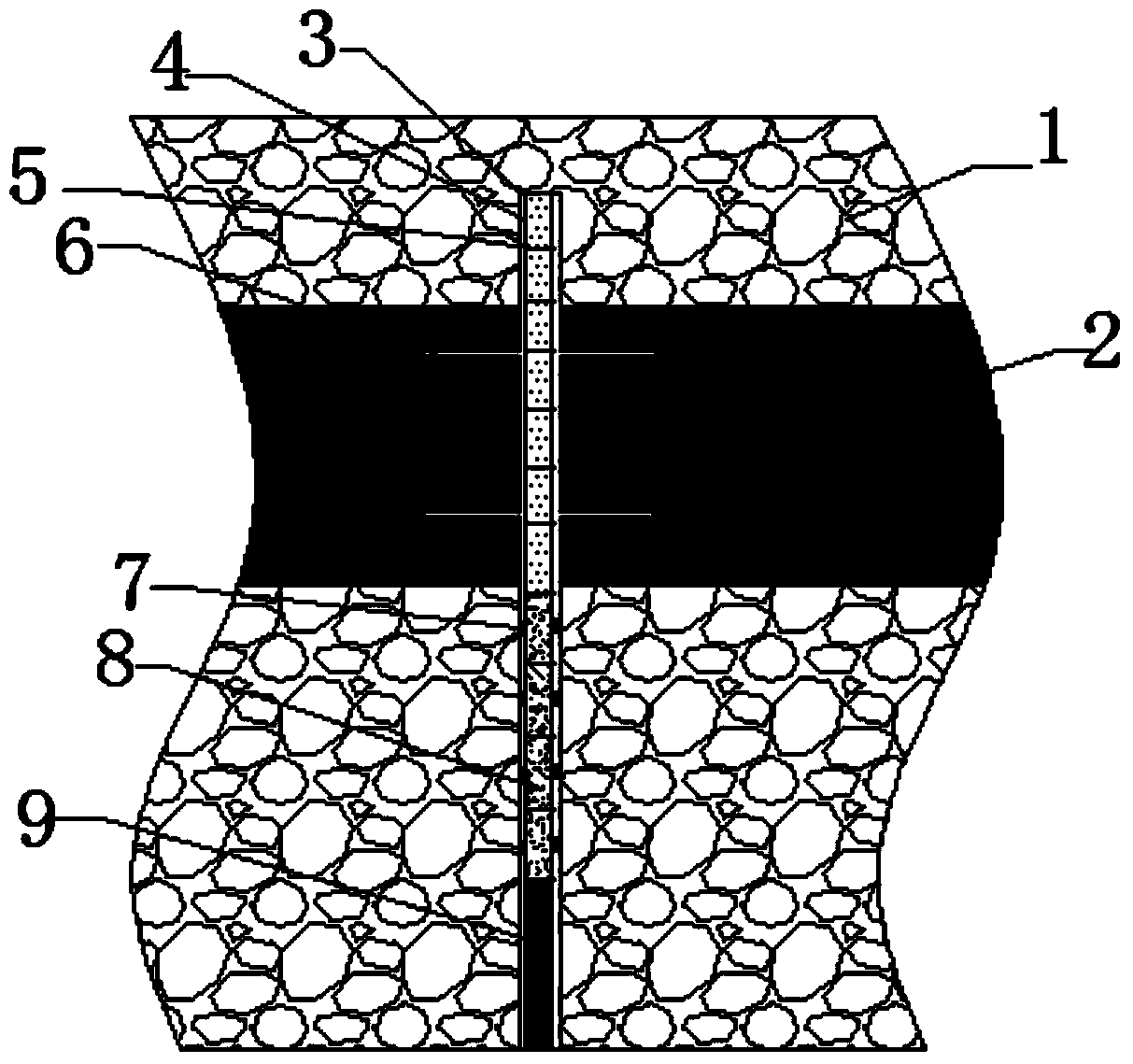

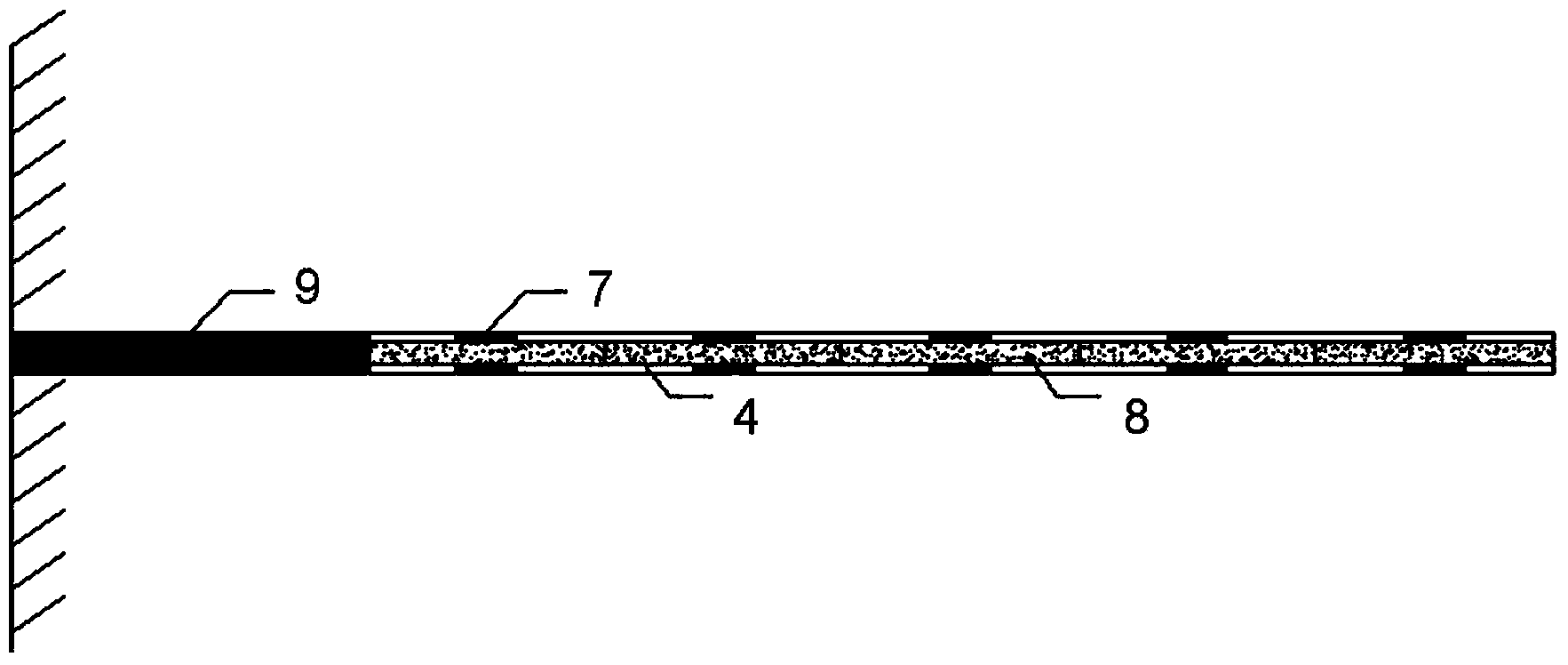

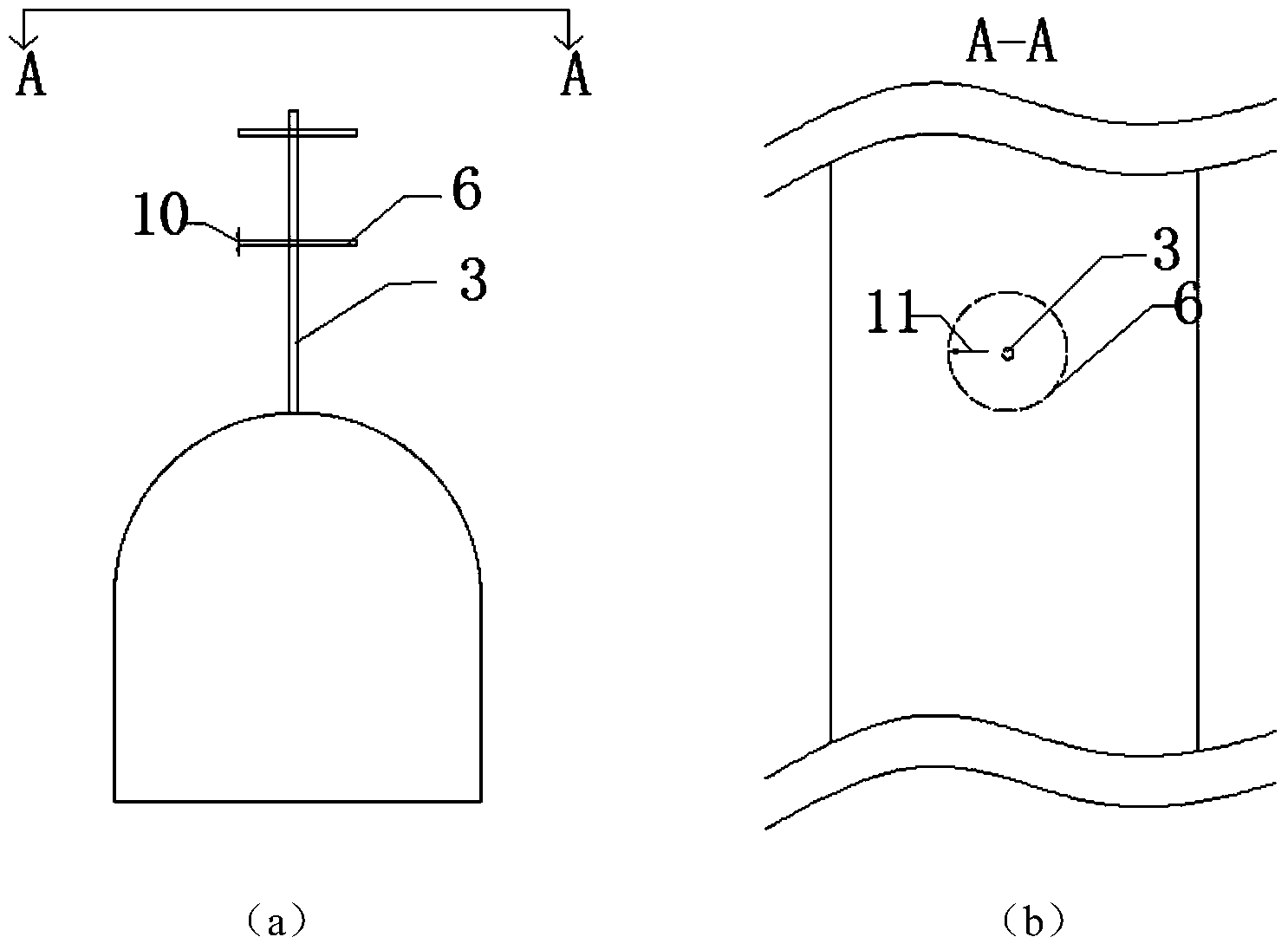

[0044] In a certain mine, the rock solidity factor is f=3, and the coal firmness factor is f=1. At the selected position, a drilling rig is used to drill holes into the coal and rock mass, such as figure 1 As shown, the thickness of rock mass 1 is 32m, the thickness of coal mass 2 is 3m, the hole depth is 36m, and the hole diameter is 113mm; then through the hole, clean up the rock powder and cinder in the drill hole, and carry out radial hydraulic cutting, as shown image 3 As shown, the (b) figure on the right is the schematic diagram of the A-A cross-section in the (a) figure on the left, in which 3 is the blast hole and 6 is the slot; then put the explosive 5 with the detonator into the PVC pipe 4, and One section of pipe is 2m long, and it is sent into 11 sections of PVC pipe; then the same length (also 2m) of PVC pipe filled with yellow sand 8 is sent into the blast hole, and 0.5m of polyurethane 7 is bound in the middle of each section to ensure that the PVC pipe In the...

Embodiment 2

[0046] In a certain mine, the solidity coefficient of rock is f=5, and the solidity coefficient of coal is f=2. At the selected position, a drilling rig is used to drill holes into the coal and rock mass. The thickness of rock mass 1 is 37m, and the thickness of coal mass 2 is 4m. The depth is 42mm, and the hole diameter is 94mm; then through the hole, clean up the rock powder and coal slag in the drill hole, and make axial slits, as shown Figure 4 The figure (b) on the right is a schematic diagram of the B-B section in the figure (a) on the left, in which 3 is the blast hole and 6 is the slot; then put the explosive 5 with the detonator into the PVC pipe 4, and the length of the pipe is 2m, into 15 sections of PVC pipe; then the same length (also 2m) of PVC pipe filled with yellow sand 8 is sent into the blast hole, and 0.5m of polyurethane 7 is bound in the middle of each section to ensure that the PVC pipe is in the blast hole In the center, send a total of 5 sections; the...

Embodiment 3

[0048]In a certain mine, the firmness factor of the rock is f=4, and the firmness factor of the coal is f=3. At the selected position, a drilling rig is used to drill holes into the coal and rock mass. The thickness of the rock mass 1 is 50m, and the thickness of the coal mass 2 is 5m. The depth is 56mm, and the hole diameter is 94mm; then through the hole, the rock powder and coal slag in the drilled hole are cleaned up, and the combination of radial slotting and axial slotting is used to prevent rockburst, as shown Figure 5 As shown, the figure (b) on the right is a schematic diagram of the C-C section in the figure (a) on the left, in which 3 is the blast hole and 6 is the slot; then put the explosive 5 with the detonator into the PVC pipe 4, and the The length is 2m, and it is sent into 25 sections of PVC pipe; then the PVC pipe filled with yellow sand 8 of the same length (also 2m) is sent into the blasthole, and 0.5m of polyurethane 7 is bound in the middle of each secti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com