Optical fiber Bragg optical grating low-temperature sensor for simultaneously measuring strain and temperature and application method thereof

A technology of sensors and temperature-measuring optical fibers, which is applied in the field of low-temperature strain and temperature sensors of optical fiber Bragg gratings, and can solve problems such as lack of effective packaging protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

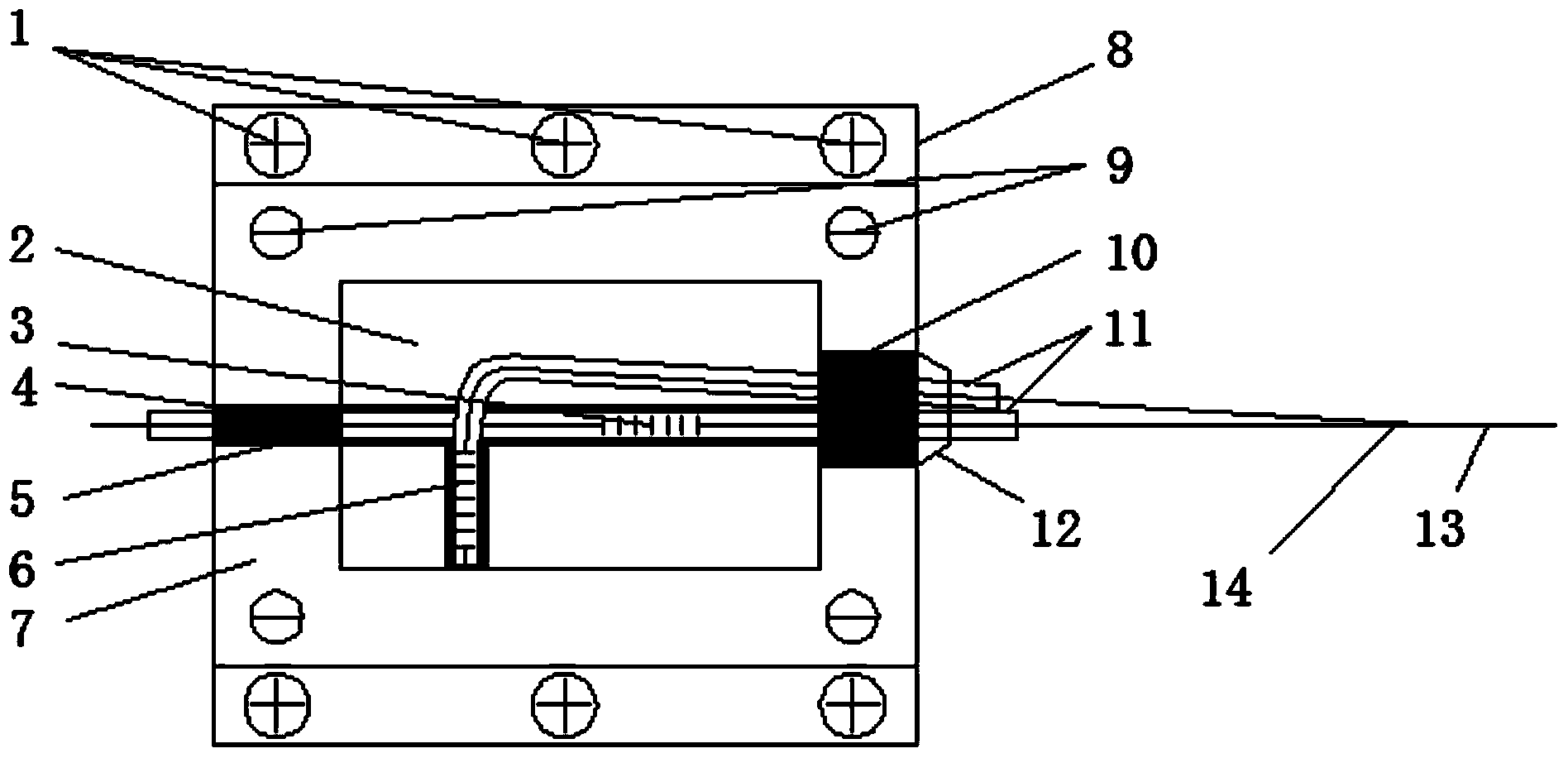

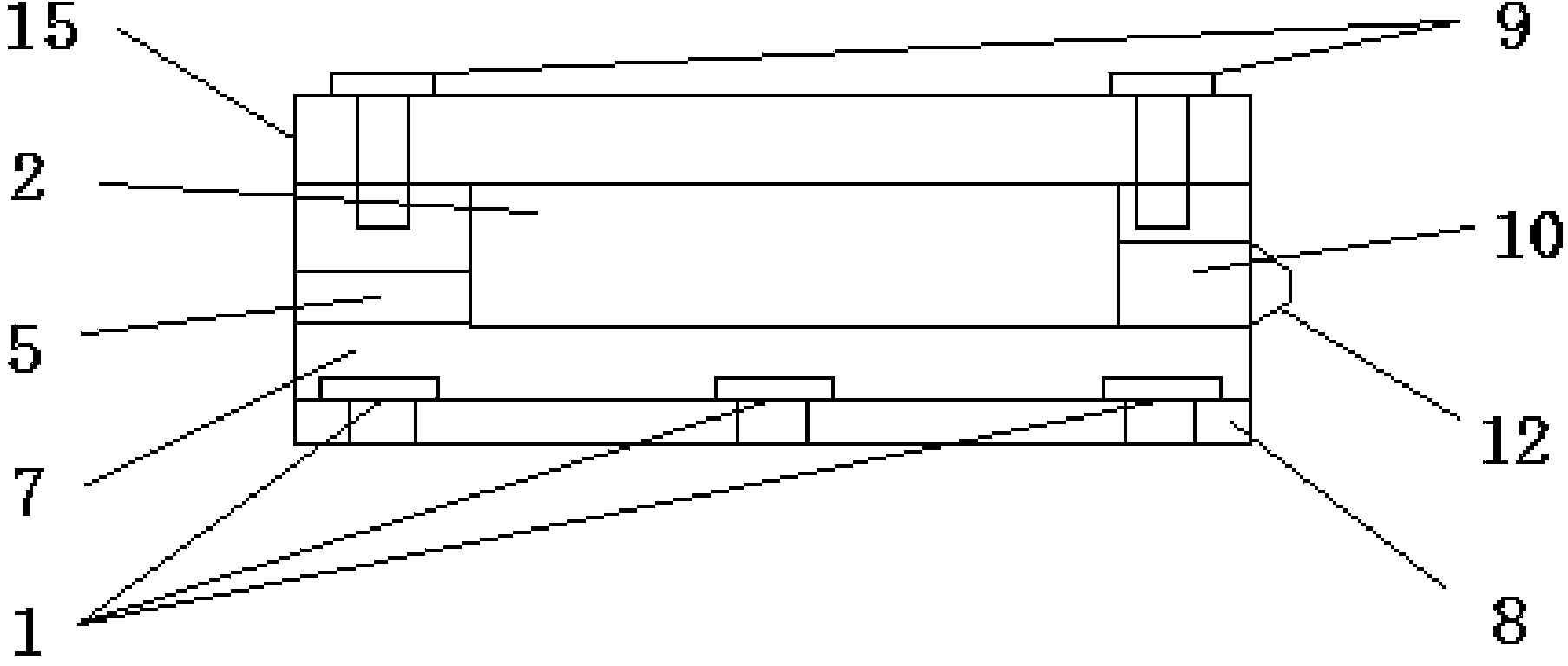

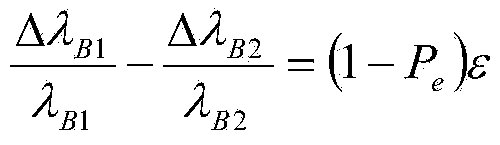

[0038] see Figure 1~2, the top cover 15 and the copper shell 7 are connected by the top cover screw 9 to form the measurement cavity 2, the copper shell 7 is fixed on the measured object by the fixed base 8 and the base fixing screw 1, the strain fiber Bragg grating 3 and the temperature measuring fiber Bragg The grating 6 is packaged with a thin copper tube 11 and a low-temperature adhesive 4, the strained fiber Bragg grating 3 is pasted along the axis direction of the bottom of the copper shell 7 with a low-temperature adhesive 4, and the temperature-measuring fiber Bragg grating 6 is glued along the vertical axis of the bottom of the copper shell 7 with a low-temperature adhesive 4 Direction paste, one end of the strained fiber Bragg grating 3 is led out through the upper fiber outlet hole 5, and fixed to the copper shell 7 with a low-temperature adhesive 4, and the other end and the temperature-measuring fiber Bragg grating 6 are led out through the lower fiber outlet hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com