A kind of cellulose blend fiber and preparation method thereof

A technology of blending fiber and cellulose, which is applied in the direction of cellulose/protein conjugated artificial filament, fiber chemical characteristics, spinning solution preparation, etc., to achieve high environmental friendliness, simple preparation method, excellent flexibility and strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

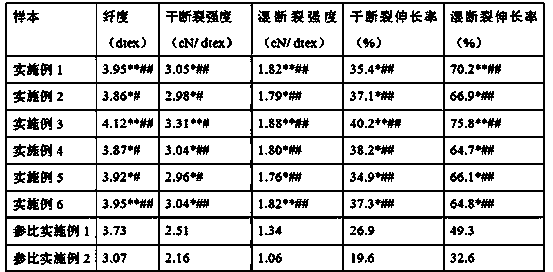

Examples

Embodiment 1

[0022] Embodiment 1 Preparation of blended fiber of the present invention

[0023] Prepare a polyacrylonitrile solution with a mass concentration of 15% and a polyvinyl alcohol solution with a mass concentration of 15%; prepare a cellulose solution with a mass concentration of 5%, and vacuum-dry chitosan and polylysine (70°C, vacuum under the condition of 100Pa and vacuum drying for 12 hours, the drying temperature is 45), and then added to the cellulose solution at 50°C to obtain the spinning stock solution, and the spinning stock solution was mixed with polyacrylonitrile solution and polyvinyl alcohol solution at 75°C uniform, so that the solution contains 60 parts of natural cellulose, 10 parts of polylysine, 3 parts of polyacrylonitrile, 2 parts of polyvinyl alcohol, and 0.5 part of chitosan, and the mixed mixture is extruded by a twin-screw extruder to obtain Blending the tow; washing the blended tow through a water tank to remove the ionic liquid, stretching, drying, cro...

Embodiment 2

[0024] Embodiment 2 Preparation of blended fiber of the present invention

[0025] Prepare a polyacrylonitrile solution with a mass concentration of 15% and a polyvinyl alcohol solution with a mass concentration of 15%; prepare a cellulose solution with a mass concentration of 5%, and vacuum-dry chitosan and polylysine (70°C, vacuum vacuum drying under the condition of 100 Pa for 12 hours, and the drying temperature is 45), then add it to the cellulose solution at 50°C to obtain the spinning stock solution, and mix the spinning stock solution with polyacrylonitrile solution and polyvinyl alcohol solution at 50°C uniform, so that the solution contains 80 parts of natural cellulose, 15 parts of polylysine, 7 parts of polyacrylonitrile, 8 parts of polyvinyl alcohol, and 3.5 parts of chitosan, and the mixed mixture is extruded by a twin-screw extruder to obtain Blending the tow; washing the blended tow through a water tank to remove the ionic liquid, stretching, drying, cross-link...

Embodiment 3

[0026] Embodiment 3 Preparation of blended fiber of the present invention

[0027] Prepare a polyacrylonitrile solution with a mass concentration of 15% and a polyvinyl alcohol solution with a mass concentration of 15%; prepare a cellulose solution with a mass concentration of 5%, and vacuum-dry chitosan and polylysine (70°C, vacuum vacuum drying under the condition of 100 Pa for 12 hours, and the drying temperature is 45), then add it to the cellulose solution at 50°C to obtain the spinning stock solution, and mix the spinning stock solution with polyacrylonitrile solution and polyvinyl alcohol solution at 50°C uniform, so that the solution contains 70 parts of natural cellulose, 12 parts of polylysine, 5 parts of polyacrylonitrile, 5 parts of polyvinyl alcohol, and 2.5 parts of chitosan, and the mixed mixture is extruded by a twin-screw extruder to obtain Blending the tow; washing the blended tow through a water tank to remove the ionic liquid, stretching, drying, cross-link...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com