Orthotropic steel bridge deck paving structure and construction method thereof

An orthotropic, steel bridge deck technology, applied in the field of traffic engineering, can solve the problems of easy deflection, easy rutting, long maintenance time, etc., to ensure driving safety, increase friction, and improve shear bonding force Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

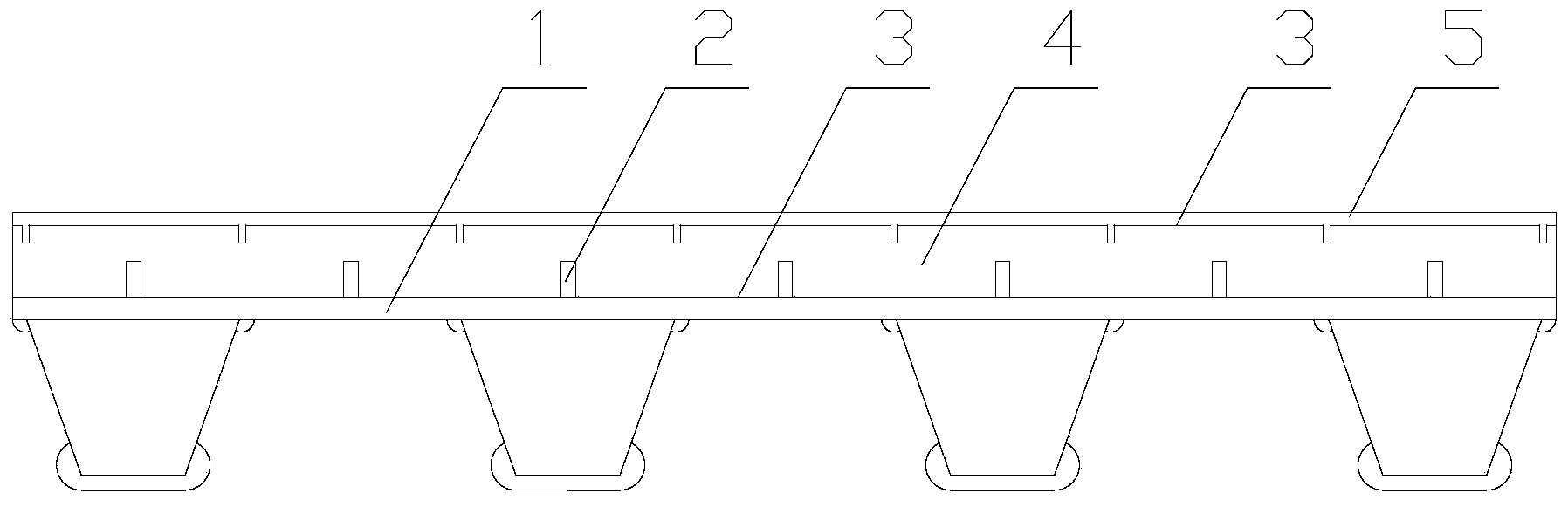

[0026] Such as figure 1 shown. The orthotropic steel bridge deck pavement structure of the present invention comprises a steel bridge deck 1, a rubber layer 4, and an aluminum alloy surface layer 5 arranged sequentially from bottom to top; the rubber layer 4 is arranged on the steel bridge deck 1 and the aluminum alloy surface between layers 5;

[0027] The upper surface of the steel bridge deck 1 is welded with shear studs 2 at equal intervals;

[0028] The upper surface of the steel bridge deck 1 is coated with an epoxy resin bonding layer.

[0029] The upper surface of the aluminum alloy surface layer 5 is provided with anti-skid grooves or transverse steel bars.

[0030] The lower surface of the aluminum alloy surface layer 5 is welded with shear-resistant convex nails at equal intervals.

[0031] The construction method of the above-mentioned orthotropic steel deck pavement structure is realized through the following steps:

[0032] 1) The rubber layer 4, the aluminu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com