Flexible shock-absorption and noise-reduction gear

A vibration and noise reduction, gear technology, applied in the direction of belts/chains/gears, components with teeth, portable lifting devices, etc., can solve the problem of limited service life and load-bearing capacity of springs, ineffective elimination of torsional vibration, acceleration or Reduce the impact and vibration problems, achieve the effect of low production cost, obvious noise reduction effect, and improve stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings.

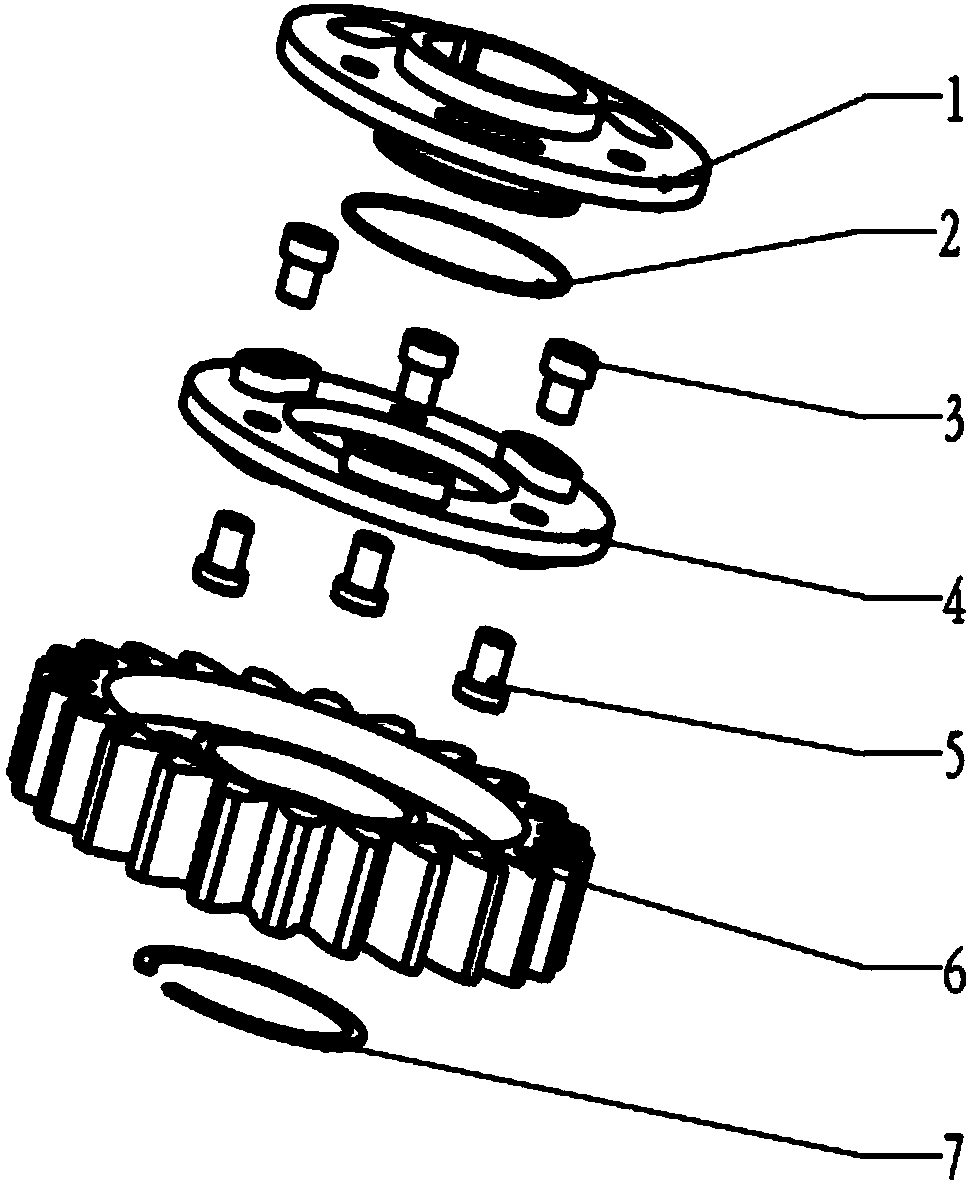

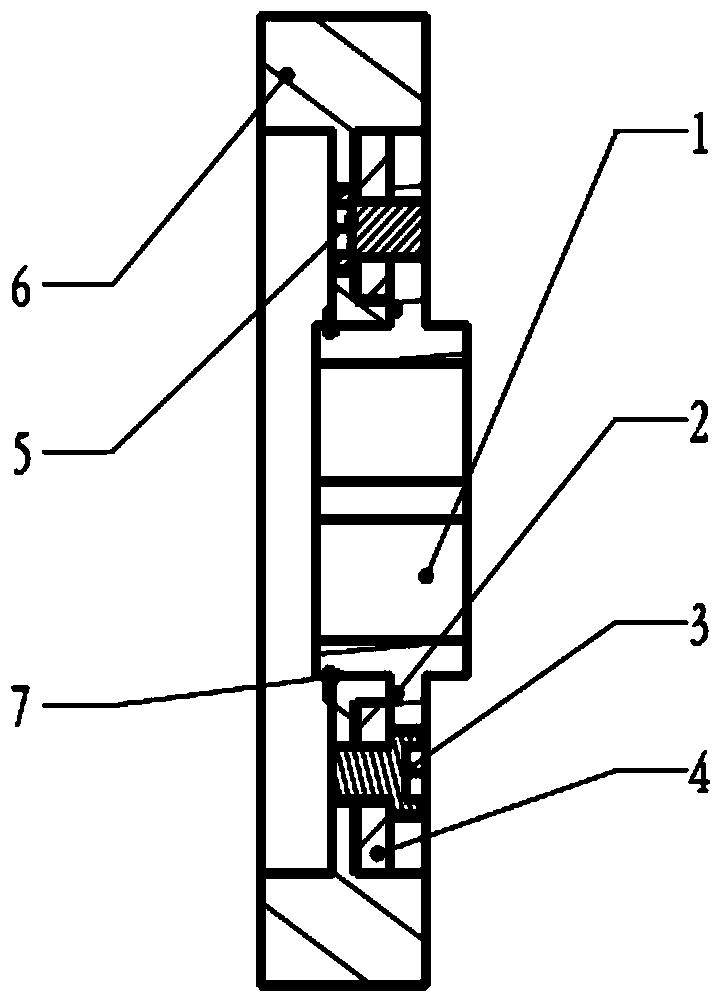

[0021] Such as figure 1 and figure 2 As shown, the flexible vibration-damping and noise-reducing gear of the present invention includes a gear body 6, a rubber damping plate 4 and a torsional pressure plate 1, and the rubber damping plate 4 is arranged between the gear body 6 and the torsional pressure plate 1, and is connected to the gear respectively. The body 6 is fixedly connected to the torsion pressure plate 1, and the power or torque is input through the torsion pressure plate 1 or the gear body 6, and then output from the gear body (6) or the torsion pressure plate (1) after passing through the rubber damping plate 4.

[0022] When working, since the rubber damping plate and the torsional pressure plate are fixedly connected before the rubber damping plate and the gear body, after the power or torque is input from the gear body or the torsional pressure pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com