Line voltage compensation circuit used for LED drive

A line voltage compensation, LED driving technology, applied in the circuit layout of electric lamps, electric light sources, electrical components, etc., can solve the problems of easy voltage interference, reduced system efficiency, limited effect of output current compensation, etc., to improve anti-interference ability. and reliability, the effect of simplifying system design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

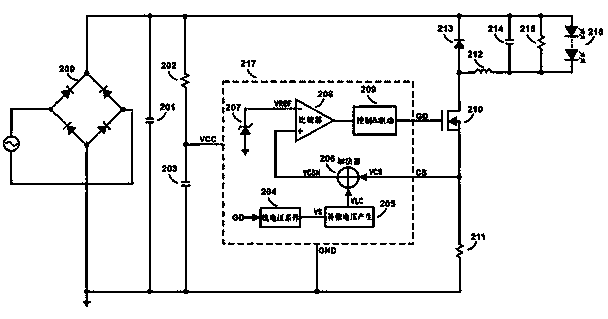

[0026] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

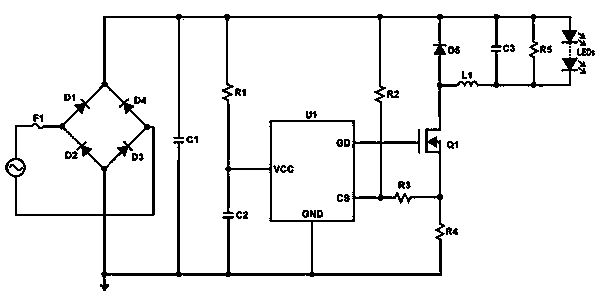

[0027] In order to solve the problems of low efficiency, high cost, large volume, and poor anti-interference ability of the traditional line voltage compensation technology, the present invention provides an integrated line voltage compensation circuit. The compensation circuit detects the conduction time of the power switch tube. The voltage on the bus is indirectly sampled, which saves the line voltage compensation resistor in the traditional technology, simplifies the system design of the external circuit, improves the system efficiency and reduces the system cost, and greatly improves the system's anti-interference ability and reliability.

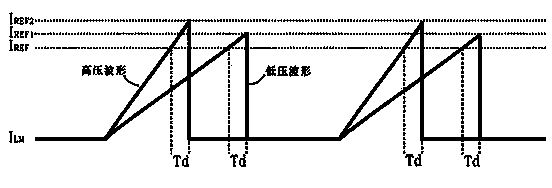

[0028] Due to the logic delay inside the control chip and the turn-off delay of the power switch tube, for the same LED constan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com