Use of DIG3 insecticidal crystal protein in combination with cry1ab

A technology of insecticidal protein and composition, which can be applied in any field and can solve problems such as delayed resistance and no cross-resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

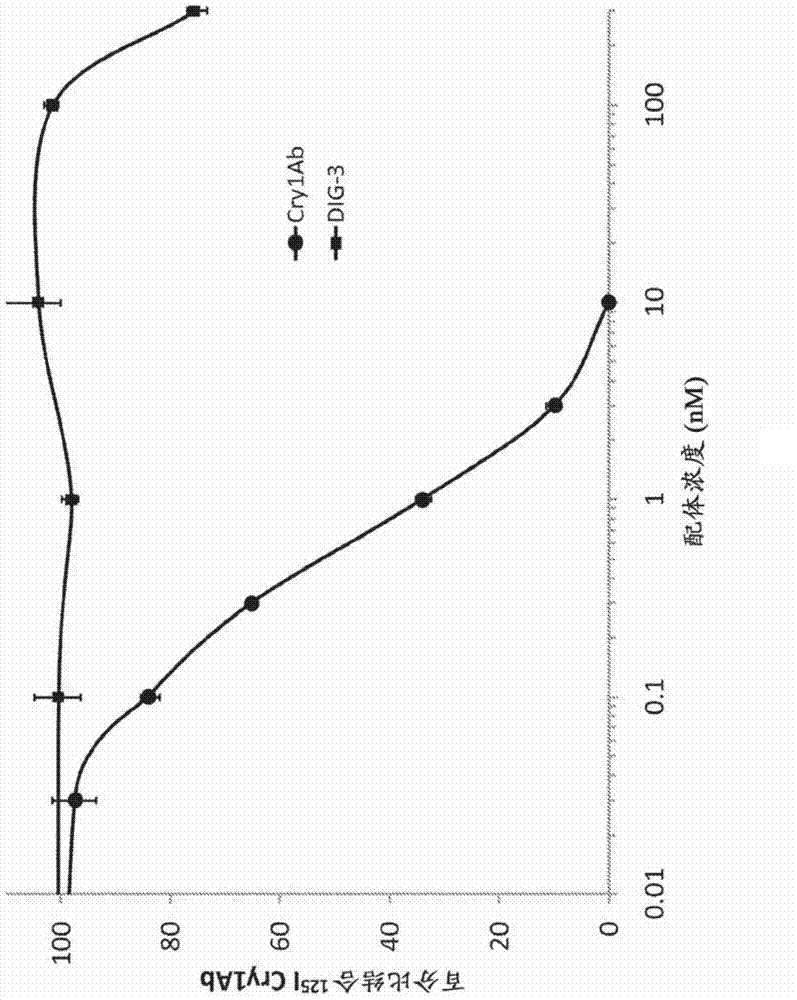

[0096] Example 1: Cry1Ab protein 125 I mark

[0097] Iodination of Cry1Ab core toxin. Cry1Ab toxin (SEQ ID NO: 1) was activated with trypsin and iodinated using iodine beads (Pierce). Briefly, two iodine beads were washed twice with 500 μl phosphate-buffered saline PBS (20 mM sodium phosphate, 0.15 M NaCl, pH 7.5) and placed into lead-shielded 1.5 ml centrifuge tubes. 100 μl of PBS are added to this. In the hood (hood) and via the use of suitable radioactive manipulation techniques, 0.5mCi Na 125 I (17.4 Ci / mg, Amersham) was added to the PBS solution with iodine beads. The components were allowed to react for 5 minutes at room temperature, then 10 μg of highly pure truncated Cry1Ab protein was added to the solution and allowed to react for an additional 5 minutes. The reaction was terminated by removing the solution from the iodine beads and applying it to 0.5 ml of a desalted Zeba spin column (InVitrogen) equilibrated in 20 mM CAPS buffer, pH 10.5 + 1 mM DTT. The ...

Embodiment 2

[0098] Embodiment 2: BBMV preparation scheme

[0099] Preparation and Fractionation of Solubilized BBMV. Last-instar Ostrivia moth larvae were fasted overnight and then dissected in the morning after cooling on ice for 15 min. The midgut tissue was removed from the body cavity, leaving the hindgut attached to the body wall. Place the midgut in 9 volumes of ice-cold homogenization buffer (300 mM mannitol, 17 mM Tris. base, pH 7.5) supplemented with protease diluted as recommended by the supplier inhibitor mixture 1 (Sigma P-2714)( 1 The final concentrations (in μM) of the mixture components were AEBSF (500), EDTA (250 mM), Bestatin (32), E-64 (0.35), Leupeptin (0.25), and aprotinin ( Aprotinin) (0.075). Homogenize the tissue with 15 strokes of a glass tissue homogenizer. MgCl by Wolfersberger (1993) 2 Precipitation method to prepare BBMV. Briefly, an equal volume of 24 mM MgCl in 300 mM mannitol 2 The solution was mixed with the midgut homogenate, stirred for 5 minut...

Embodiment 3

[0100] Example 3: Measurement 125 The method that I Cry1Ab protein binds to BBMV protein

[0101] 125 I Binding of Cry1Ab protein to BBMV. To determine the optimal amount of BBMV protein to use in the binding assay, a saturation curve was generated. will pass 125 I radiolabeled Cry1Ab protein (0.5nM) and binding buffer (8mM NaHPO 4 ,2mM KH 2 PO 4 , 150 mM NaCl, 0.1% bovine serum albumin, pH 7.4), various amounts of BBMV proteins ranging from 0-500 μg / ml were incubated together at 28° C. for 1 hour. The total volume is 0.5ml. will be combined as follows 125 I Cry1Ab protein was separated from unbound protein by sampling 150 μl of reaction mixture in triplicate from 1.5 ml centrifuge tubes into 500 μl centrifuge tubes and centrifuging samples at 14,000 x g for 6 minutes at room temperature. The supernatant was gently removed and the pellet was gently washed three times with ice-cold binding buffer. The bottom of the centrifuge containing the pellet was cut out an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com