Automatic sand blasting and derusting system on inner wall of pipeline

A technology of sand blasting and rust removal and piping, applied in spray guns, abrasive jetting machine tools, used abrasive processing devices, etc., can solve problems such as low degree of automation and hazards, and achieve high construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

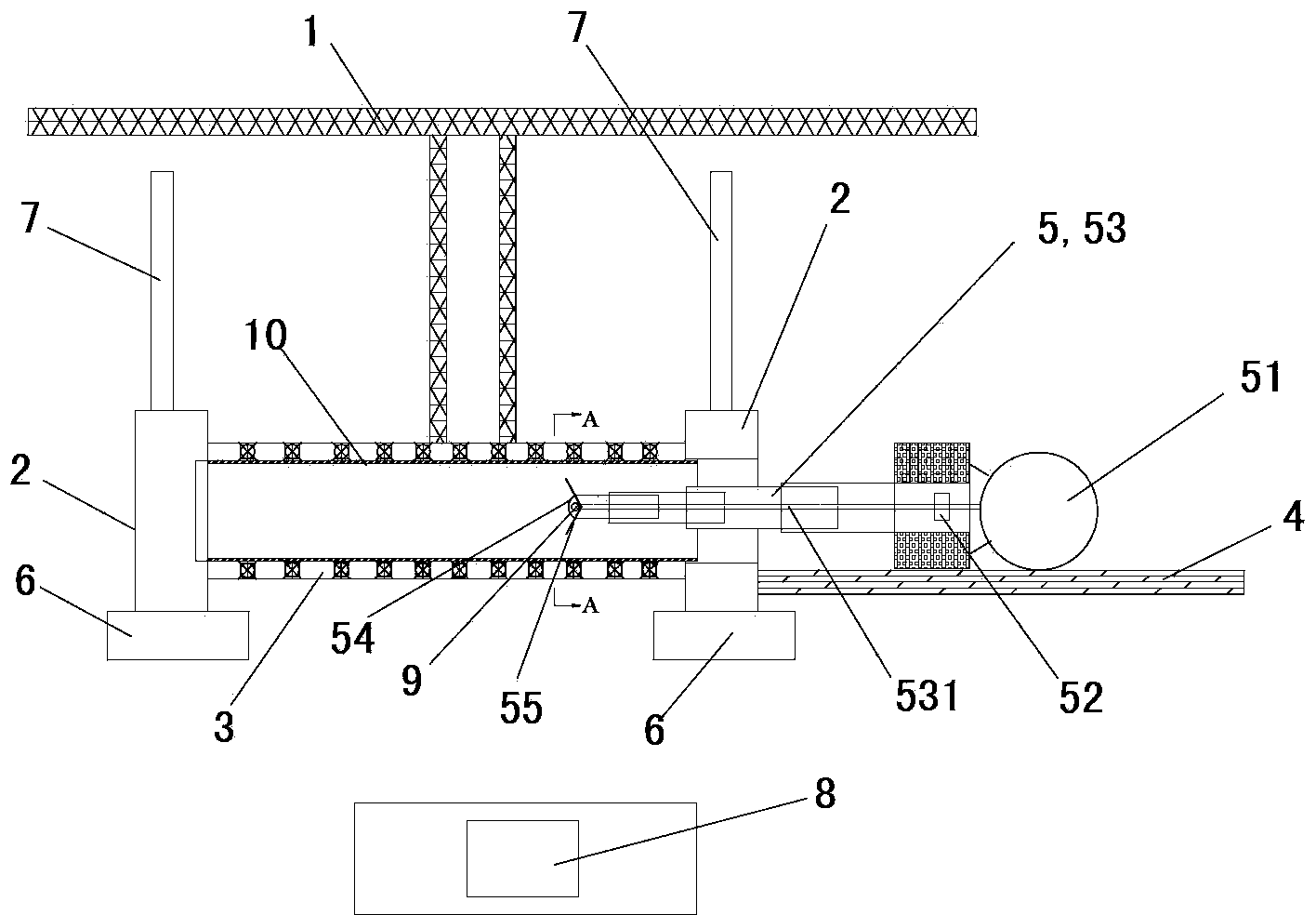

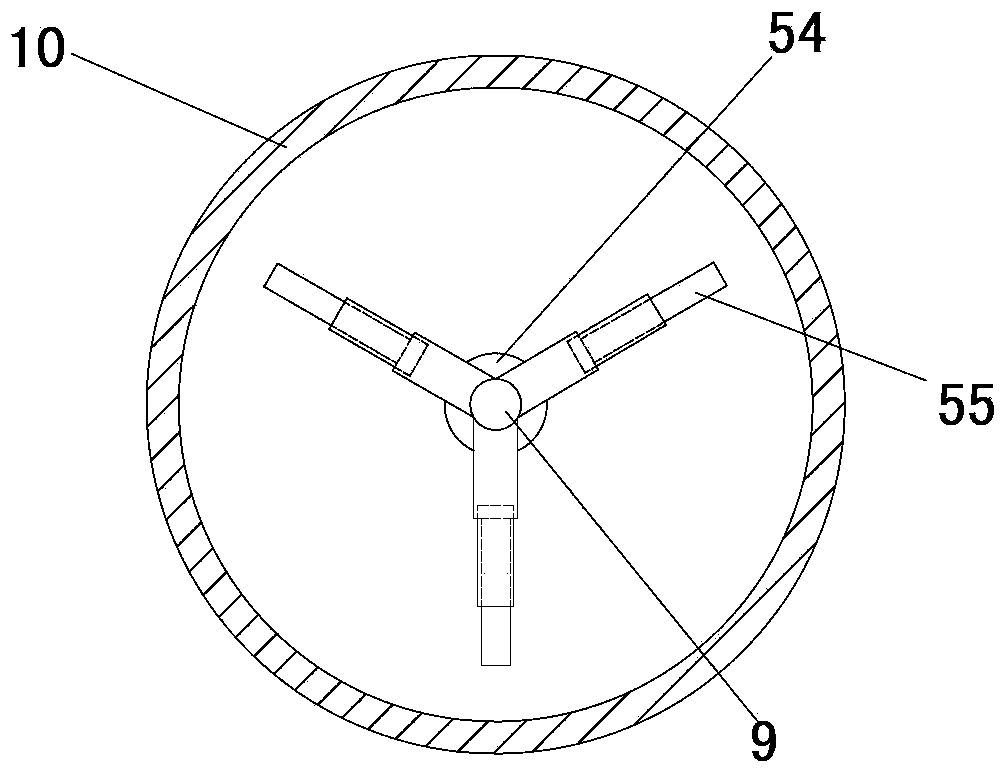

[0024] see figure 1 , the automatic noise spraying and derusting system for the inner wall of the pipeline of the present invention includes a crane hoisting mechanism 1, two metal boxes 2, a steel pipe positioning and rotating mechanism 3, a track 4, a sandblasting mechanism 5, two sand collection tanks 6, and two dust removal Air duct 7, automatic control computer 8 and detection device 9. The crane hoisting mechanism 1 is set above the system; the two metal boxes 2 are arranged at intervals under the crane hoisting mechanism; the steel pipe positioning and rotating mechanism 3 is set between the two metal boxes; the track 4 is set at the rear of the system The sandblasting mechanism 5 is erected on the track and can move along the track, and its front end passes through the back metal box to protrude forward; the two sand collecting grooves 6 are respectively connected under the two metal boxes; the two dust removal air ducts 7 are respectively connected to Above the two m...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap