An etching process and device for improving sidewall streaks

A streak and process technology, applied in the field of etching process and its devices, can solve the problems of polymer sidewall streaks, high DC bias, and polymer weight, and achieve the effect of improving the streaks of through holes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

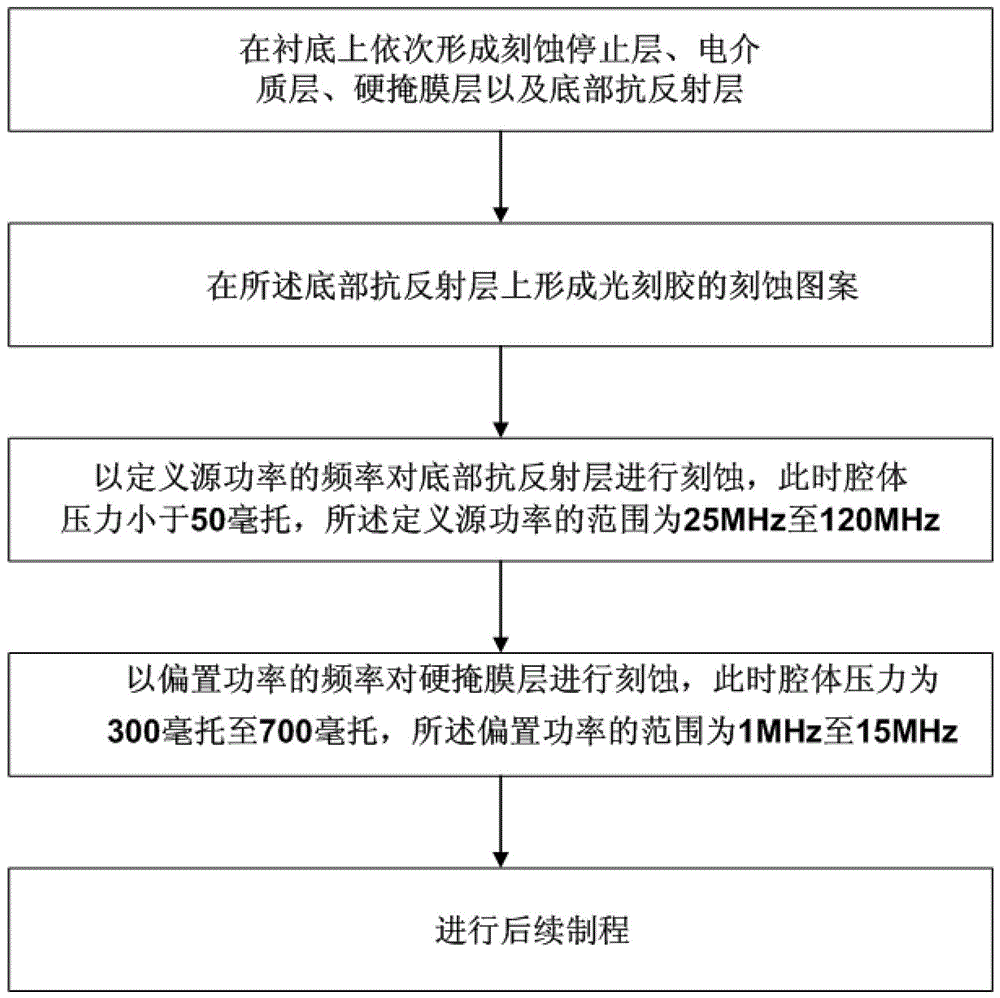

[0076] Using the etching process and device for improving sidewall streaks of the present invention to etch the bottom dielectric isolation layer includes the following specific steps:

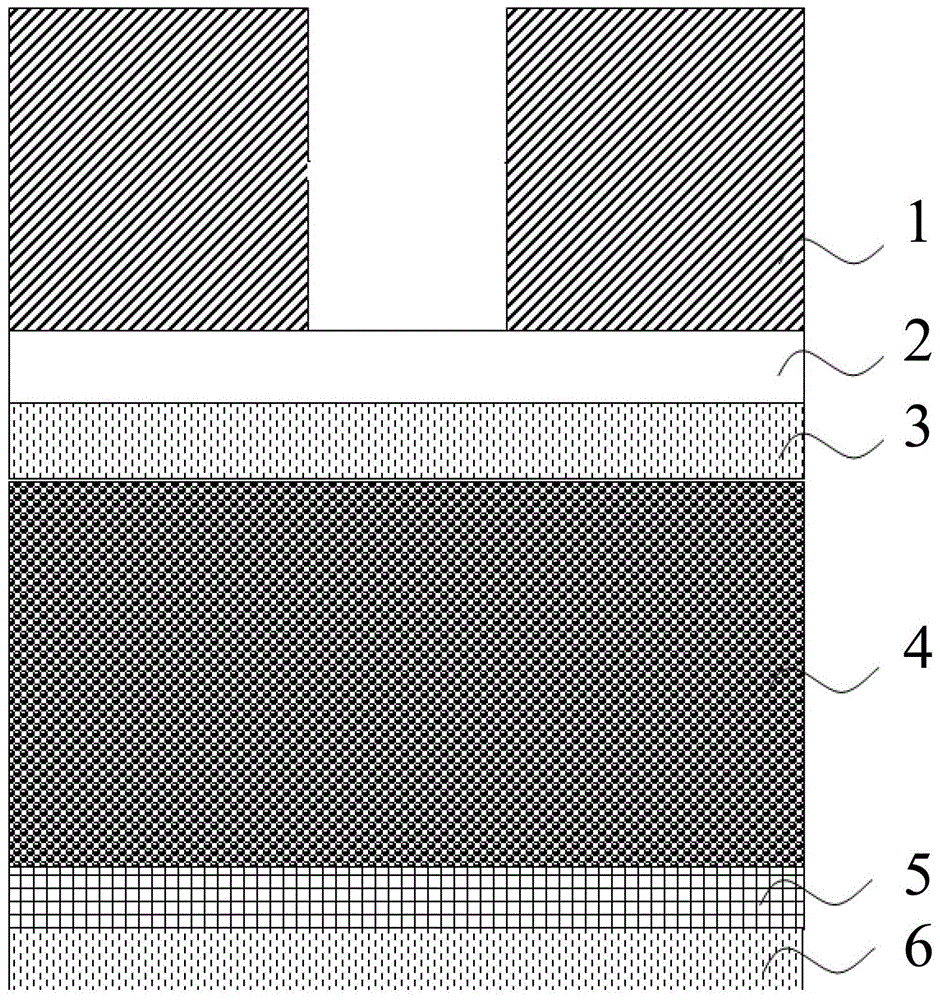

[0077] The substrate is placed on the pedestal in the plasma reaction chamber, and an etching stop layer, a dielectric layer, a hard mask layer and a bottom anti-reflection layer are sequentially formed on the substrate.

[0078] An etching pattern of photoresist is formed on the bottom anti-reflection layer.

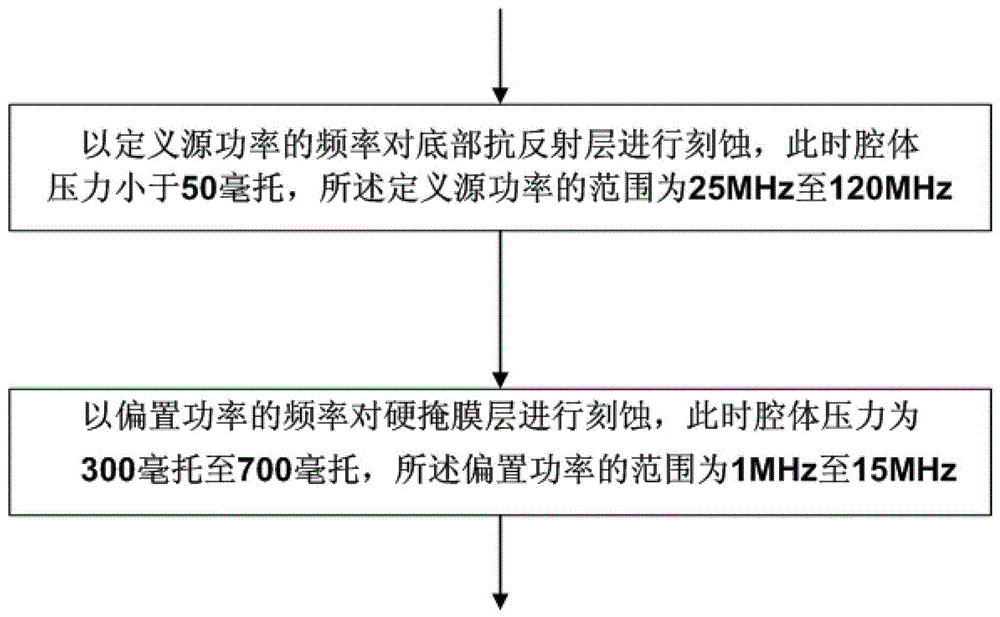

[0079] The plasma generator in the plasma reaction chamber etches the bottom anti-reflection layer at a frequency that defines the source power. At this time, the chamber pressure is 45 mTorr, and the mixed gas introduced during the etching of the bottom anti-reflection layer includes: N 2 and CO 2 The mixed gas, the defined source power is 60MHz.

[0080] Then the plasma generator etches the hard mask layer at the frequency of the bias power, and the cavity pressure is 600 millitorr ...

Embodiment 2

[0084] Using the etching process and device for improving sidewall streaks of the present invention to etch the bottom dielectric isolation layer includes the following specific steps:

[0085] The substrate is placed on the pedestal in the plasma reaction chamber, and an etching stop layer, a dielectric layer, a hard mask layer and a bottom anti-reflection layer are sequentially formed on the substrate.

[0086] An etching pattern of photoresist is formed on the bottom anti-reflection layer.

[0087] The plasma generator in the plasma reaction chamber etches the bottom anti-reflection layer at a frequency that defines the source power. At this time, the chamber pressure is 40 mTorr, and the mixed gas introduced during the etching of the bottom anti-reflection layer includes: N 2 and O 2 The mixed gas, the defined source power is 70MHz.

[0088] Then the plasma generator etches the hard mask layer at the frequency of the bias power. At this time, the chamber pressure is 500 ...

Embodiment 3

[0092] Using the etching process and device for improving sidewall streaks of the present invention to etch the bottom dielectric isolation layer includes the following specific steps:

[0093] The substrate is placed on the pedestal in the plasma reaction chamber, and an etching stop layer, a dielectric layer, a hard mask layer and a bottom anti-reflection layer are sequentially formed on the substrate.

[0094] An etching pattern of photoresist is formed on the bottom anti-reflection layer.

[0095] The plasma generator in the plasma reaction chamber etches the bottom anti-reflection layer at a frequency that defines the source power. At this time, the chamber pressure is 35 mTorr, and the mixed gas introduced during the etching of the bottom anti-reflection layer includes: N 2 and CO 2 The mixed gas, the defined source power is 65MHz.

[0096] Then the plasma generator etches the hard mask layer at the frequency of the bias power. At this time, the chamber pressure is 550...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com