A kind of preparation method of solid oxide fuel cell gasket

A solid oxide, fuel cell technology, used in fuel cell parts, fuel cells, sealing/supporting devices, etc., can solve problems such as excess material recovery, and achieve the effect of eliminating waste recycling and saving raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

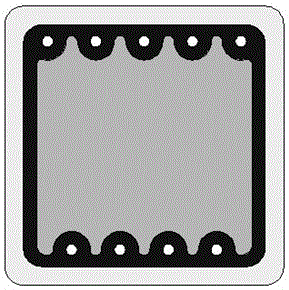

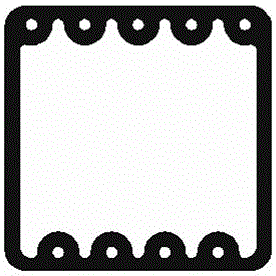

Image

Examples

Embodiment 1

[0037] Weigh 160g of sealing material powder, add 35g of butyl acetate solvent, add 7g of dispersant, and use a planetary ball mill at 300 rpm for 1 hour to mix. Then add 5g of binder and 5g of plasticizer, and use a planetary ball mill at a speed of 399 rpm for 1 hour to mix evenly to obtain a stable slurry with a moderate viscosity. After the slurry is sieved through a 80-mesh sieve and subjected to vacuum defoaming treatment, it is coated on a mold, dried and molded to obtain a sealing gasket.

Embodiment 2

[0039] Weigh 150g of sealing material powder, add 35g of butyl acetate solvent, add 6g of dispersant, and use a planetary ball mill at 350 rpm for 1 hour to mix. Then add 5g of binder and 5g of plasticizer, and use a planetary ball mill at a speed of 400 rpm for 1 hour to mix evenly to obtain a stable slurry with a moderate viscosity. After the slurry is sieved through a 100-mesh sieve and vacuum degassed, it is coated on a mold, dried and molded to obtain a sealing gasket.

Embodiment 3

[0041] Weigh 160g of sealing material powder, add 35g of butyl acetate solvent, add 8g of dispersant, and use a planetary ball mill at 290 rpm for 2 hours to mix. Then add 6g of binder and 5g of plasticizer, and use a planetary ball mill at a speed of 399 rpm for 2 hours to mix evenly to obtain a stable slurry with a moderate viscosity. After the slurry is sieved through a 150-mesh sieve and subjected to vacuum defoaming treatment, it is coated on a mold, dried and molded to obtain a sealing gasket.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com