Vibrating motor

A vibration motor and end cover technology, which is applied in the direction of electric components, magnetic circuit rotating parts, and mechanical energy control, can solve the problems of complex manufacturing process, large air gap, and low vibration efficiency, and achieve simple manufacturing process, small size, The effect of increasing the amount of vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to allow those skilled in the art to better understand the technical solution of the present invention, the present invention will be further elaborated below.

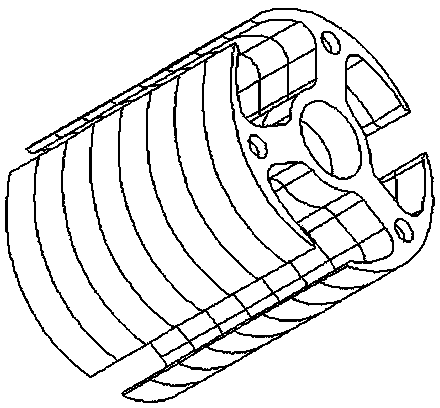

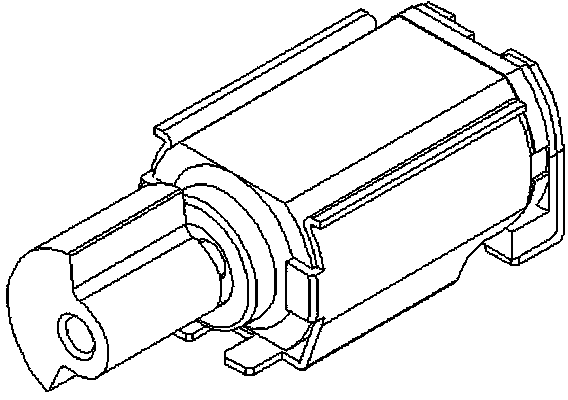

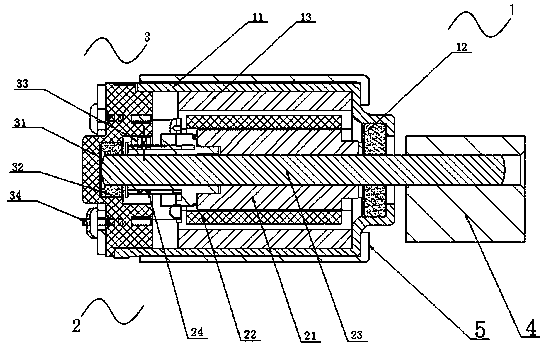

[0016] A small vibration motor, including a stator group 1, a circular rotor group 2, and an end cover group 3. The stator group 1 includes a stator casing 11, a permanent magnet 13 that fits the inner wall of the stator casing, and a stator bearing 12. The permanent magnet is a permanent magnet It is a permanent magnet material after magnetization; the end cover group 3 includes an end cover 31, an end cover bearing 32 nested in the end cover 31, a brush 33 and a power terminal 34, and the brush 33 is arranged on the end cover bearing 32. On both sides of the center, brushes 33 are connected to an external DC power supply through energized terminals 34; the rotor group includes a slotless cylindrical support part 21, a coil 22, a commutator 24 and a central shaft 23, and the slotless cylindrical shape ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com