System for operating an electric tractive unit

A technology for operating systems and electric locomotives, which is applied in the field of systems for operating electric locomotives and vehicles to achieve the effect of small structure size and reliable transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

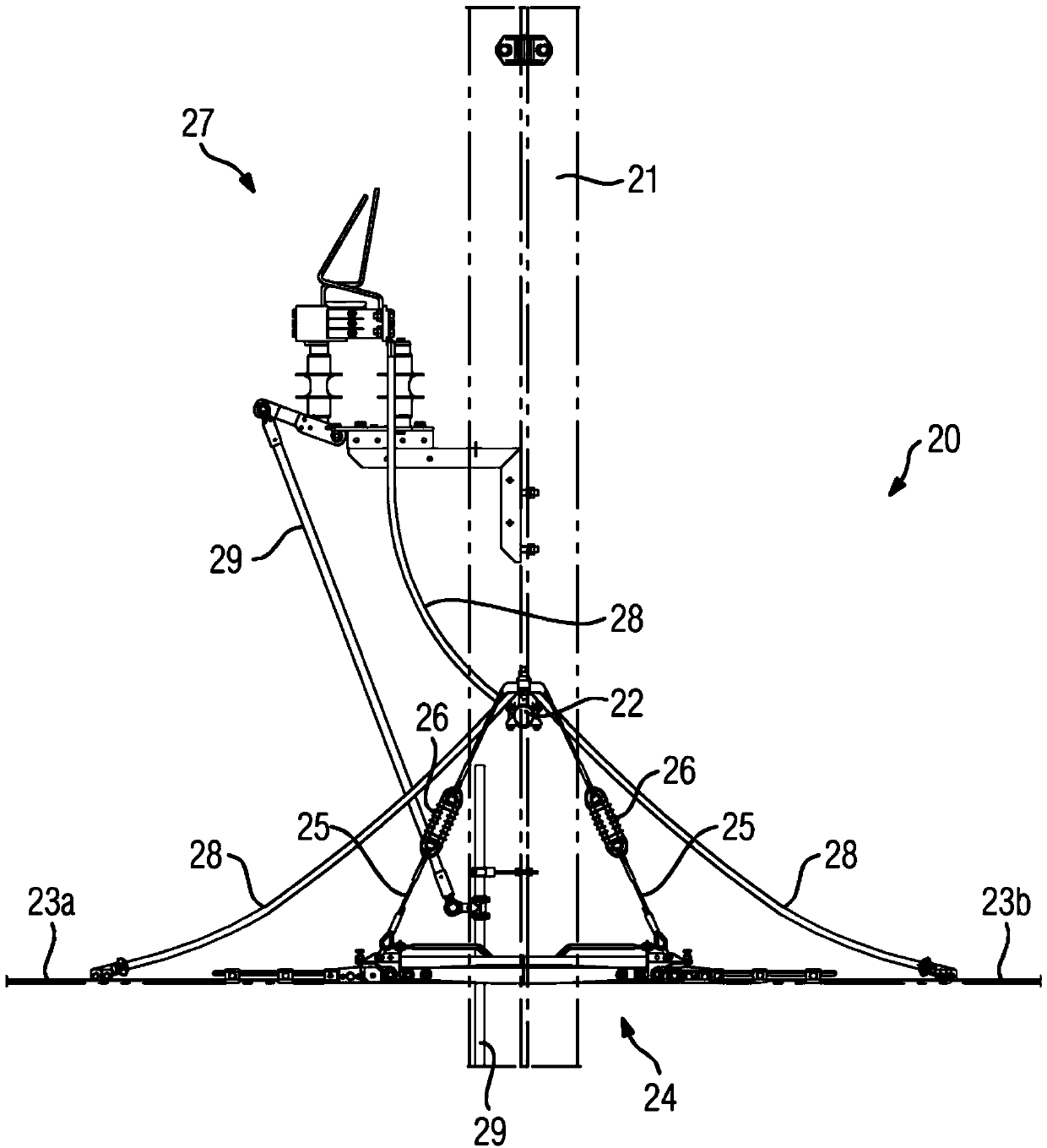

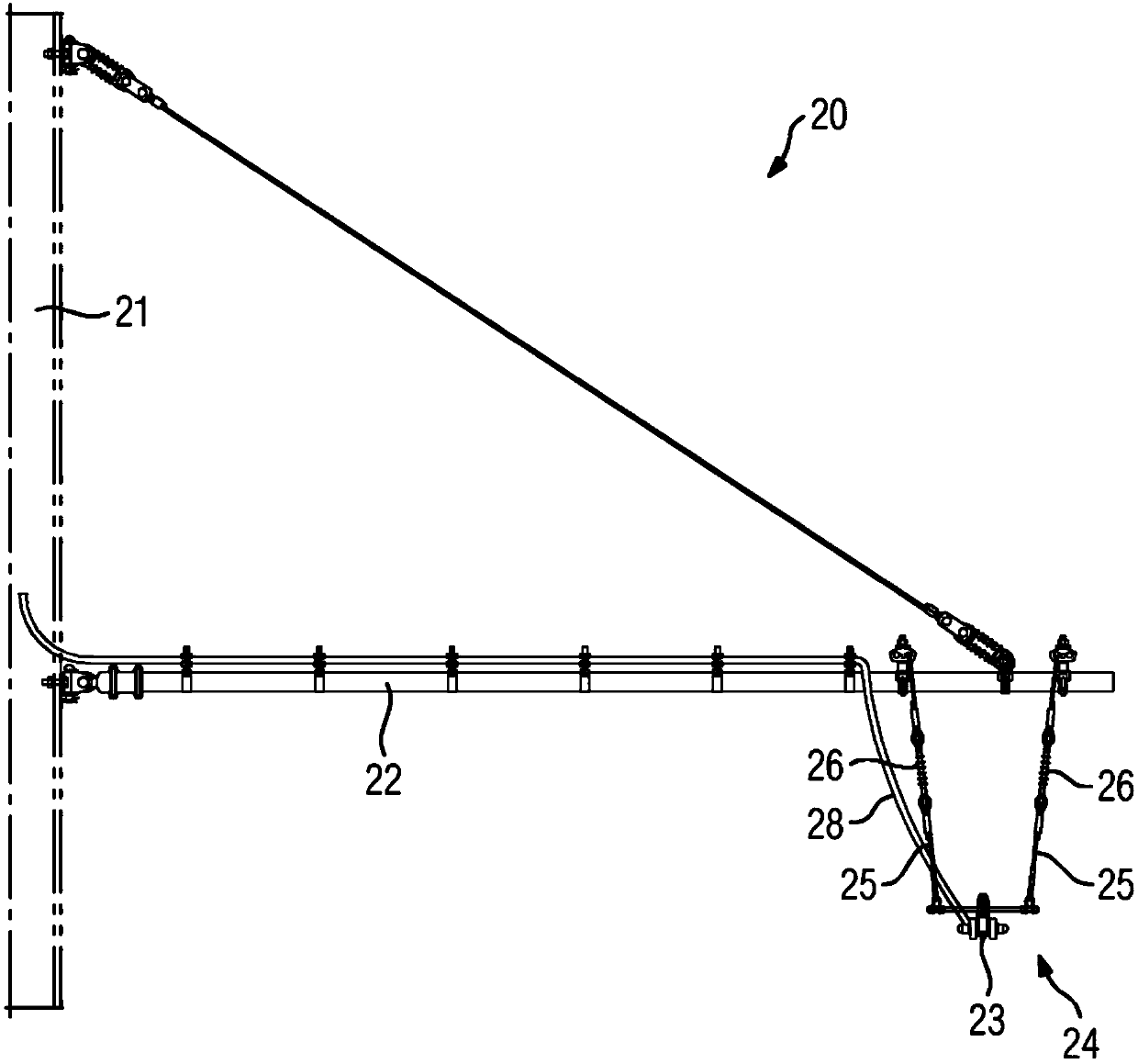

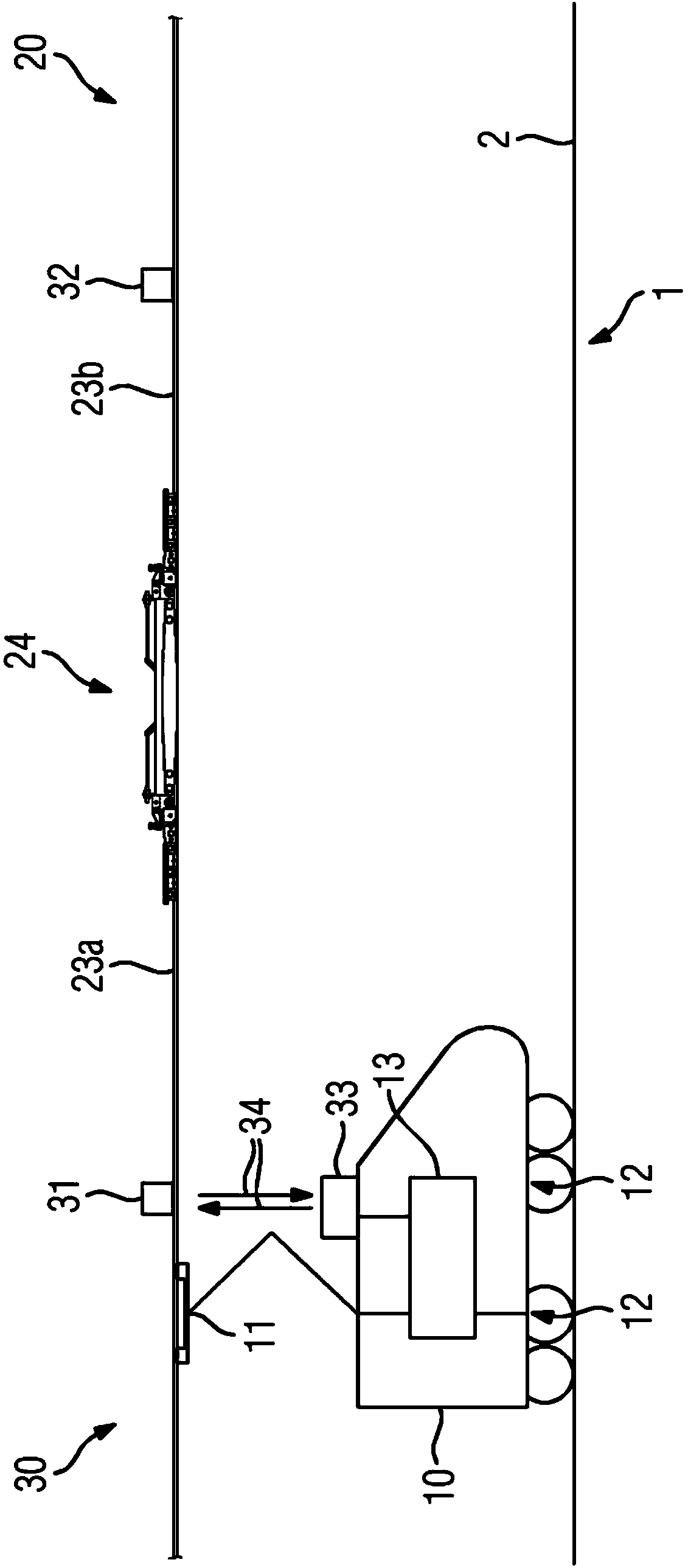

[0031] according to image 3 The electric rolling stock 10, such as short-distance traffic rail electric rolling stock, is passed according to figure 1 and figure 2 The contact wire device 20 is supplied with electrical energy. The contact line system 20 is designed as an overhead line system with a contact line 23 carried by a catenary system. For this purpose, a line pylon 21 is erected along the track 2 of the electric rolling stock 10 , on which a cantilever frame 22 protruding laterally from the track 2 is rotatably supported. In the region of the illustrated wire tower 21, the contact wire arrangement 20 has a separation point in which the contact wire 23 formed as an antenna wire is divided into two contact wire parts 23a and 23b which are electrically isolated from each other . The contact conductor arrangement 20 has a section switch 24 in a separating position, via which the contact conductor parts 23a and 23b are connected to each other in an insulated manner. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com