Vertical pulverizer for grinding ultrafine powder

A pulverizer and ultra-fine powder technology, applied in grain processing, etc., can solve the problems of poor steady-state control characteristics of hydraulic mechanisms, poor powder fineness and consistency, weak anti-interference ability, etc., and achieve good steady-state control Ideal characteristics, powder fineness and consistency, and strong anti-interference ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

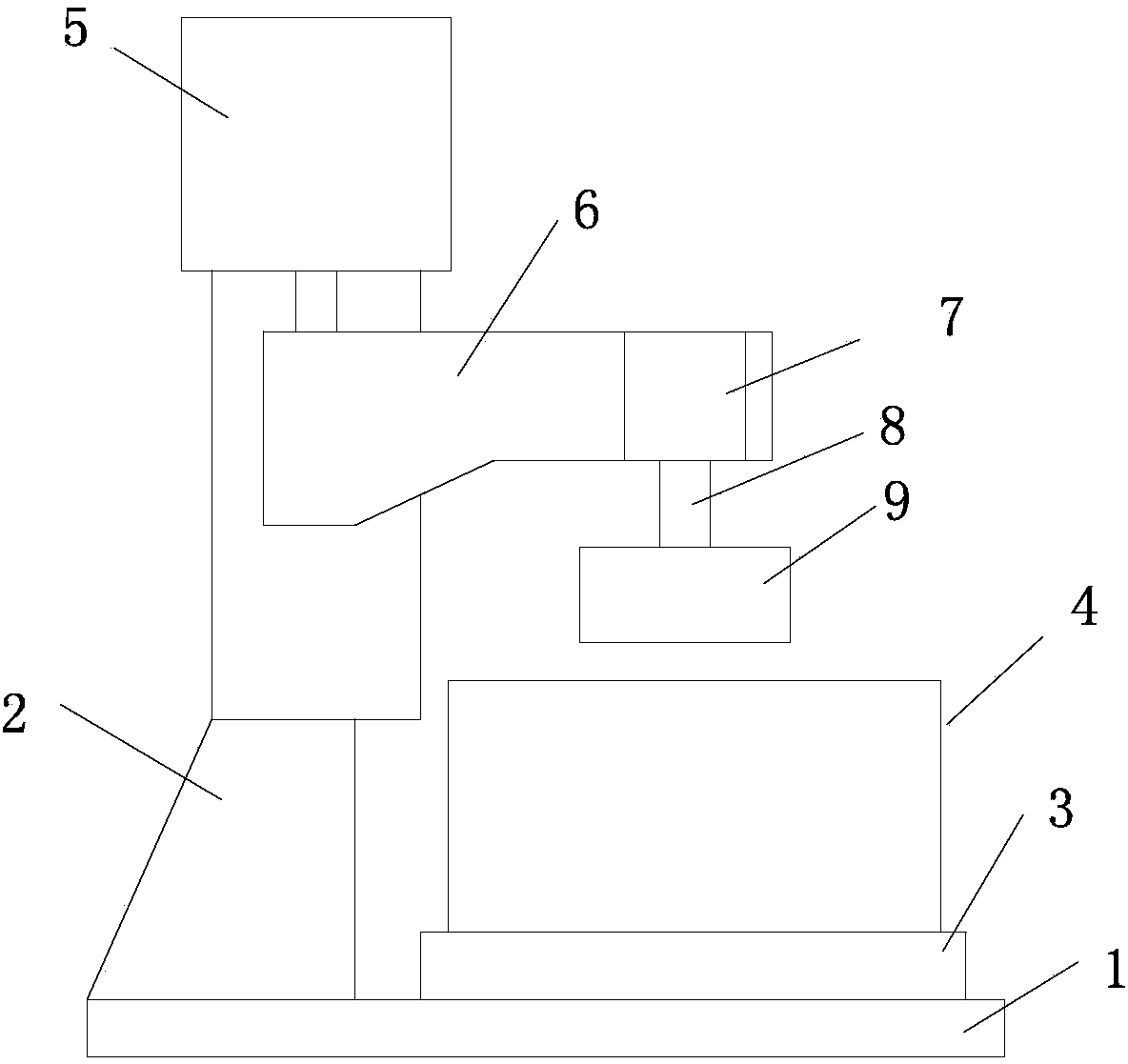

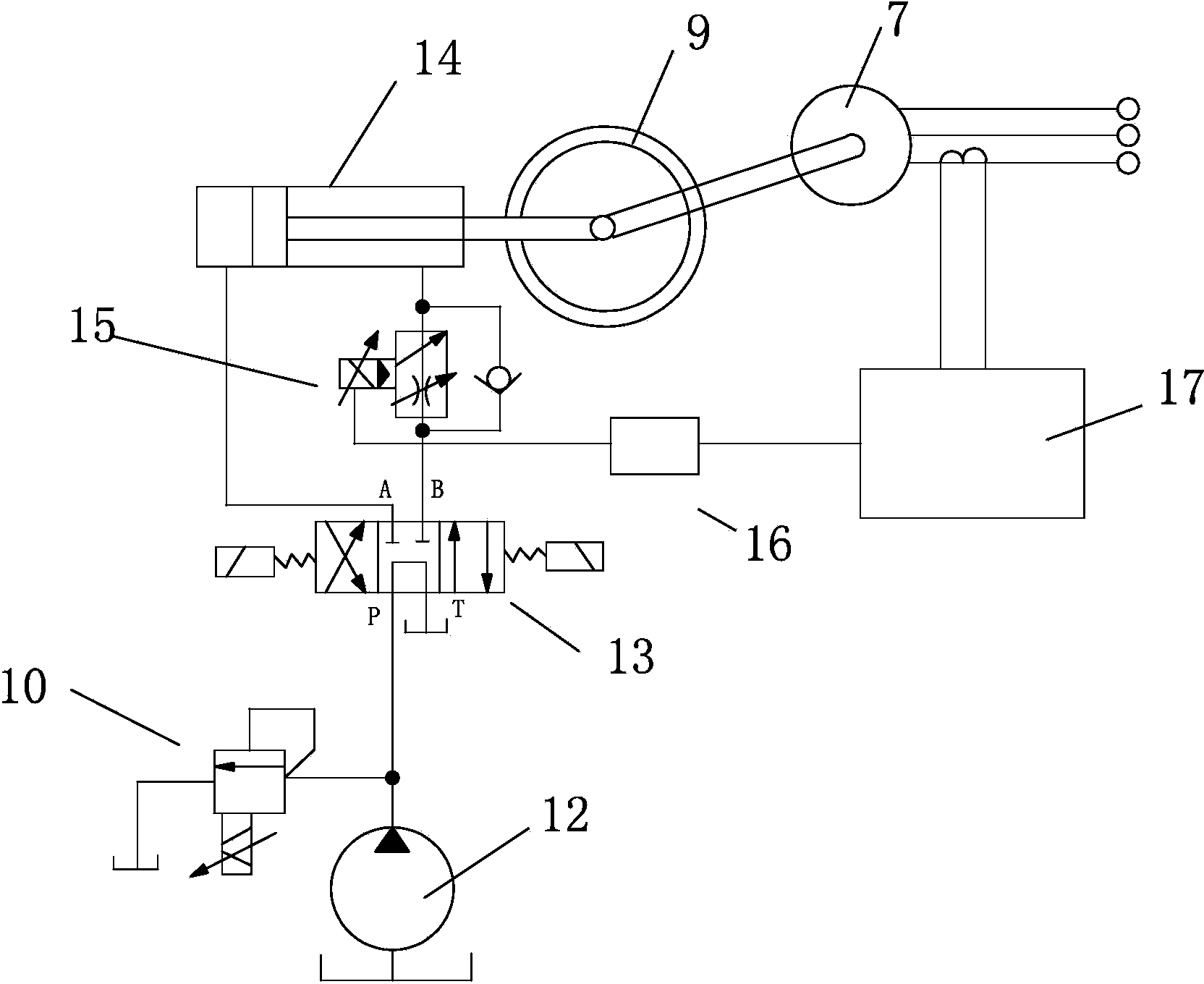

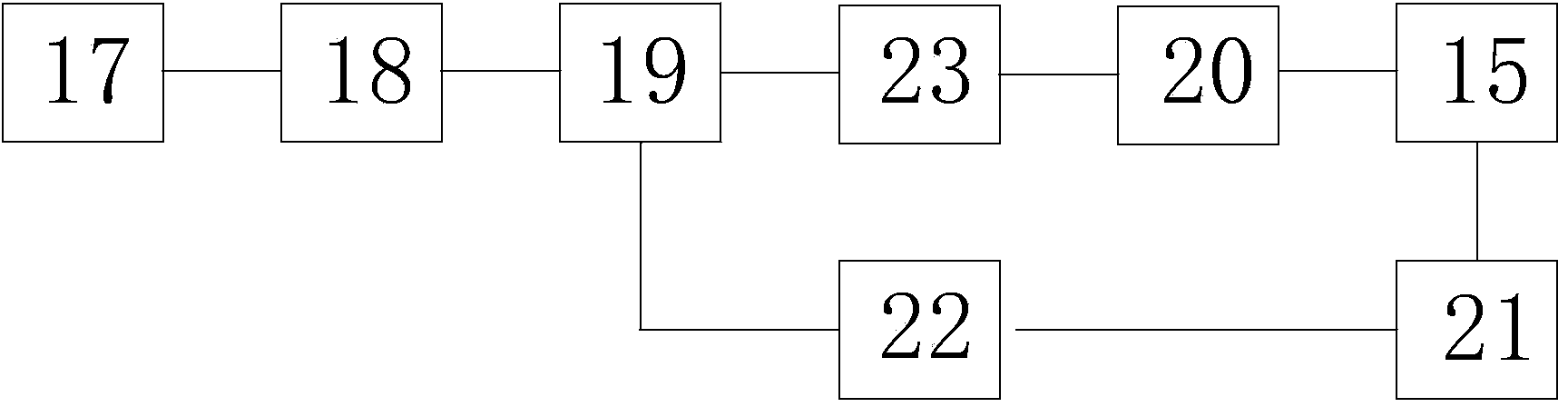

[0021] Embodiment: a kind of vertical pulverizer of grinding superfine powder, as attached figure 1 And attached figure 2 As shown, it includes a mechanical mechanism and a hydraulic mechanism. The mechanical mechanism includes a chassis 1, the top of the chassis 1 is a frame 2, the bottom of the chassis 1 is a workbench 3, and the workbench 3 is provided with a crushing groove 4; The upper part of the frame 2 is provided with a hydraulic cylinder 5, the 5 extension ends of the hydraulic cylinder are provided with a cantilever 6, the end of the cantilever 6 is provided with a motor 7, the output end of the motor 7 is provided with a main shaft 8, and the bottom of the main shaft 8 is connected with The crushing hub 9 is placed above the crushing tank 4; the hydraulic mechanism includes an oil pump 12, and the oil pump 12 is connected to a three-position four-way solenoid valve 13 through the P oil circuit, four three-position four-way solenoid valves The paths are respective...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com