Coating for producing tubular high-silicon cast iron positive electrode and preparation method of coating

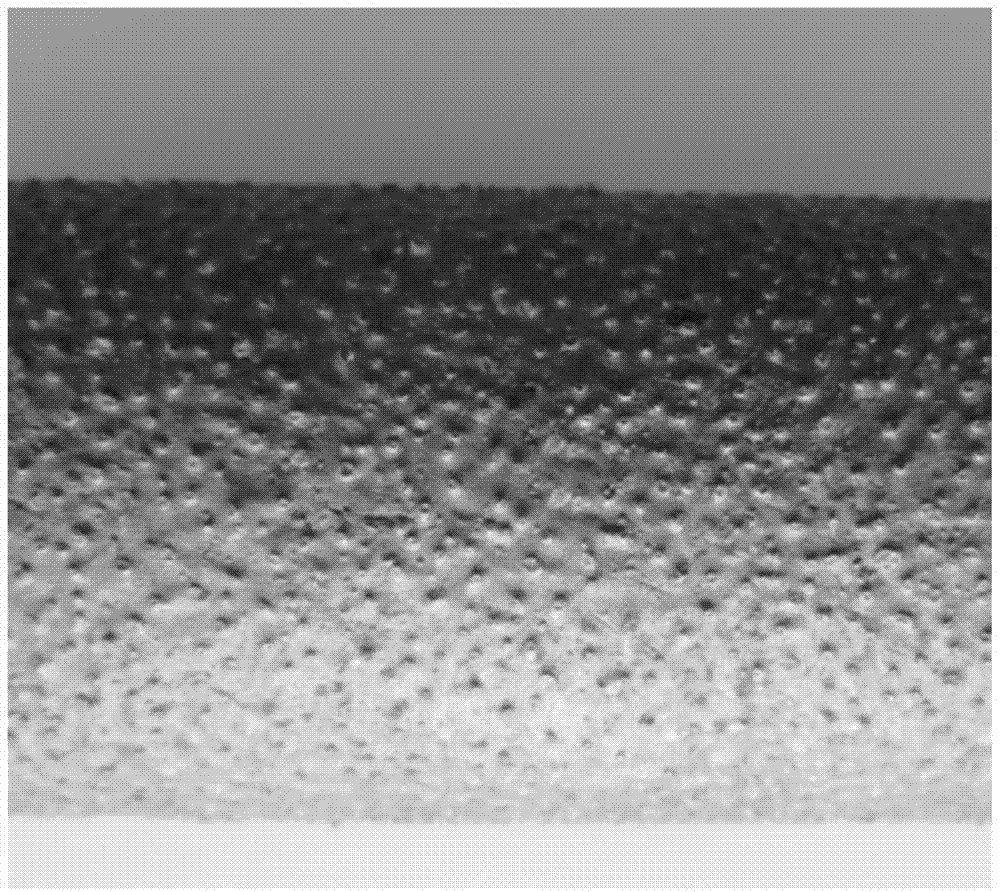

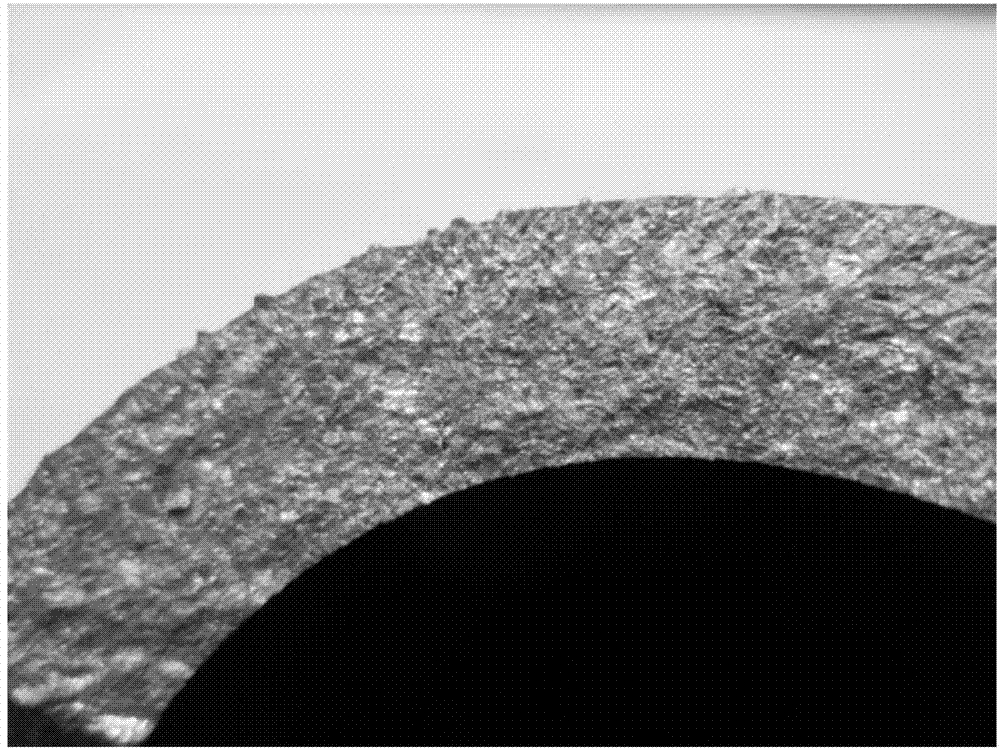

A high-silicon cast iron, tubular technology, applied in casting molding equipment, coatings, casting molds, etc., can solve the problem of affecting the electron diffusion of high-silicon cast iron anodes, difficulty in obtaining uniformly distributed pockmarks, and affecting the radiation heat transfer effect of radiant tubes, etc. problems, to achieve the effect of improving suspension, improving surface quality and mixing uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A kind of production method that is used to produce the coating of high-silicon cast iron tubular anode, it comprises the following steps:

[0029] (1) Crushing, rolling and sieving the diatomite, expanded perlite powder, zircon powder and sodium bentonite in the components to obtain a powder whose mesh number is greater than or equal to 250 mesh (in this case, 250 mesh ), of course, you can also directly buy diatomite, expanded perlite powder, zircon powder and sodium bentonite that meet the requirements in the market;

[0030] (2) Dry mix the diatomite, expanded perlite powder, zircon powder, sodium bentonite and dextrin crushed in step (1) in proportion. After mixing evenly, put them into the mixer container and add Silica sol, water, soaking time is 7 hours, fully stirred with a mixer to obtain water-soluble paint, stirring time is 7 hours, the specific ratio is: diatomite 25%, expanded perlite powder 2.5%, zircon powder 10% %, sodium bentonite 2%, dextrin 2% (in t...

Embodiment 2

[0033] A kind of production method that is used to produce the coating of high-silicon cast iron tubular anode, it comprises the following steps:

[0034] (1) Crushing, rolling and sieving the diatomite, expanded perlite powder, zircon powder and sodium bentonite in the components to obtain a powder with a mesh size greater than or equal to 250 mesh (300 mesh in this example) ), of course, you can also directly buy diatomite, expanded perlite powder, zircon powder and sodium bentonite that meet the requirements in the market;

[0035] (2) Dry mix the diatomite, expanded perlite powder, zircon powder, sodium bentonite and dextrin crushed in step (1) in proportion. After mixing evenly, put them into the mixer container and add Silica sol, water, soaking time is 8 hours, stir fully with a mixer to get water-soluble paint, stirring time is 8 hours, of course, the stirring time can be extended according to the actual situation, the specific ratio is: diatomaceous earth 27%, Expand...

Embodiment 3

[0038] A kind of production method that is used to produce the coating of high-silicon cast iron tubular anode, it comprises the following steps:

[0039] (1) Crushing, rolling and sieving the diatomite, expanded perlite powder, zircon powder and sodium bentonite in the components to obtain a powder with a mesh size greater than or equal to 250 mesh (300 mesh in this example) ), of course, you can also directly buy diatomite, expanded perlite powder, zircon powder and sodium bentonite that meet the requirements in the market;

[0040] (2) Dry mix the diatomite, expanded perlite powder, zircon powder, sodium bentonite and dextrin crushed in step (1) in proportion. After mixing evenly, put them into the mixer container and add Silica sol, water, soaking time is 9 hours, stir fully with a mixer to get water-soluble paint, stirring time is 9 hours, of course, the stirring time can be extended according to the actual situation, the specific ratio is: diatomite 28%, Expanded perlit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| flame retardant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com