Metal powder tube forming die and metal powder tube preparation method

A metal powder and tube forming technology, which is applied in the field of metal powder tube forming dies and metal powder tube preparation, can solve problems such as limitations, and achieve the effects of improving yield, reducing adhesion, and reducing the difficulty of assembly and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In conjunction with the accompanying drawings, the present invention is described in detail, but the scope of protection of the present invention is not limited to the following examples, that is, all simple equivalent changes and modifications made with the patent scope of the present invention and the content of the specification are still patents of the present invention. covered.

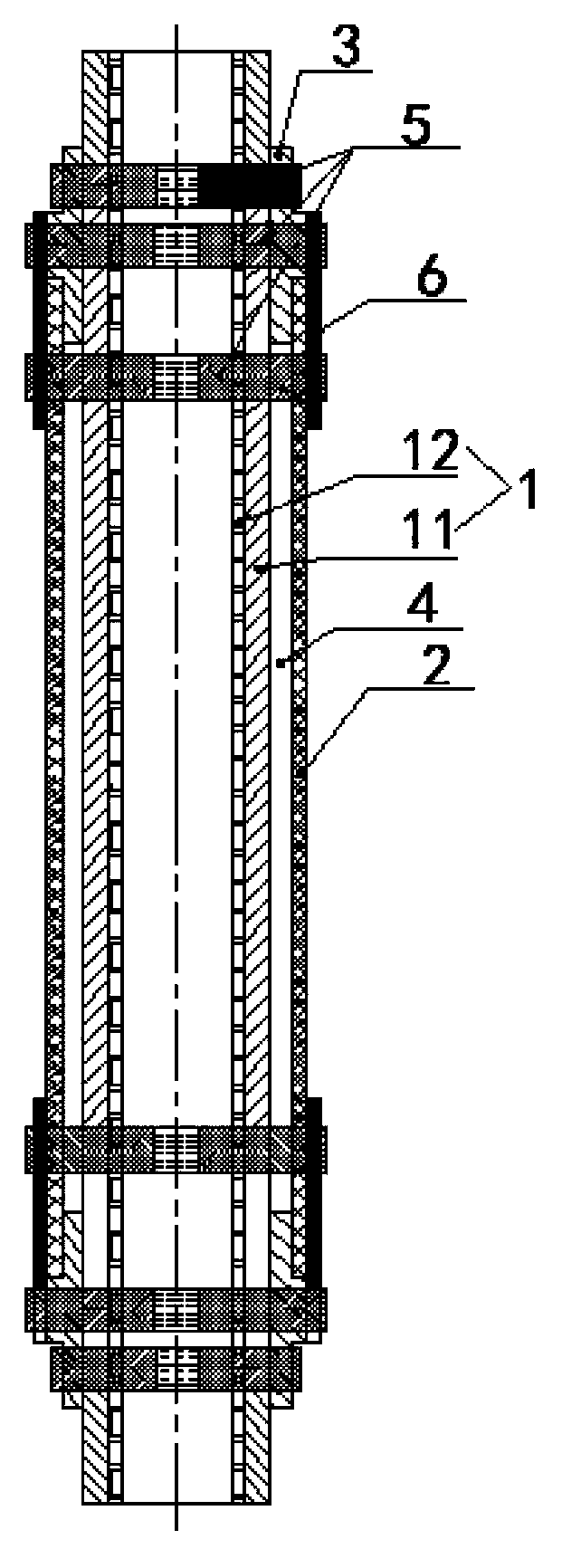

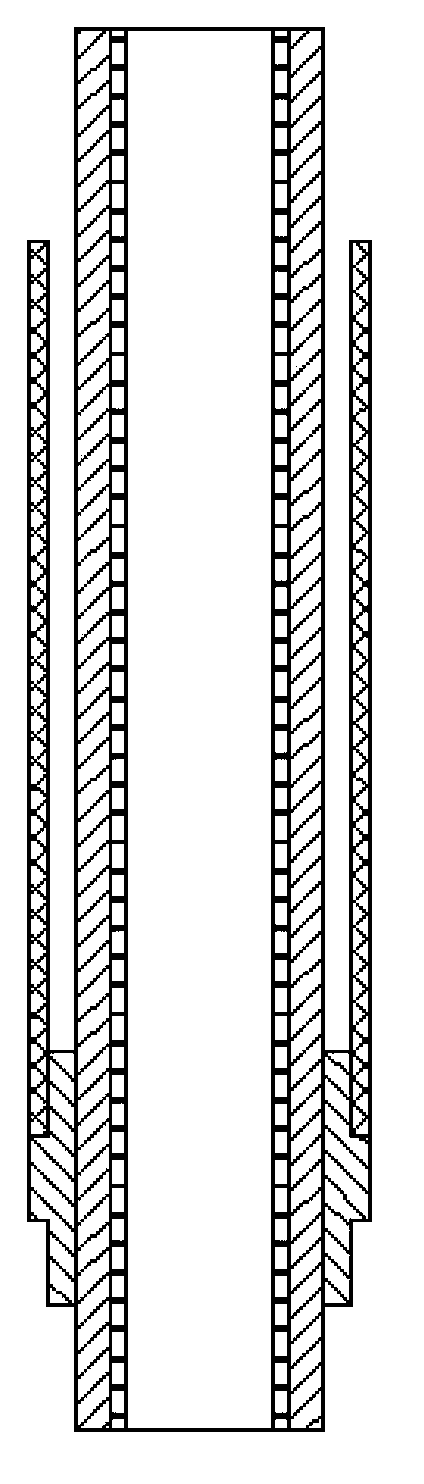

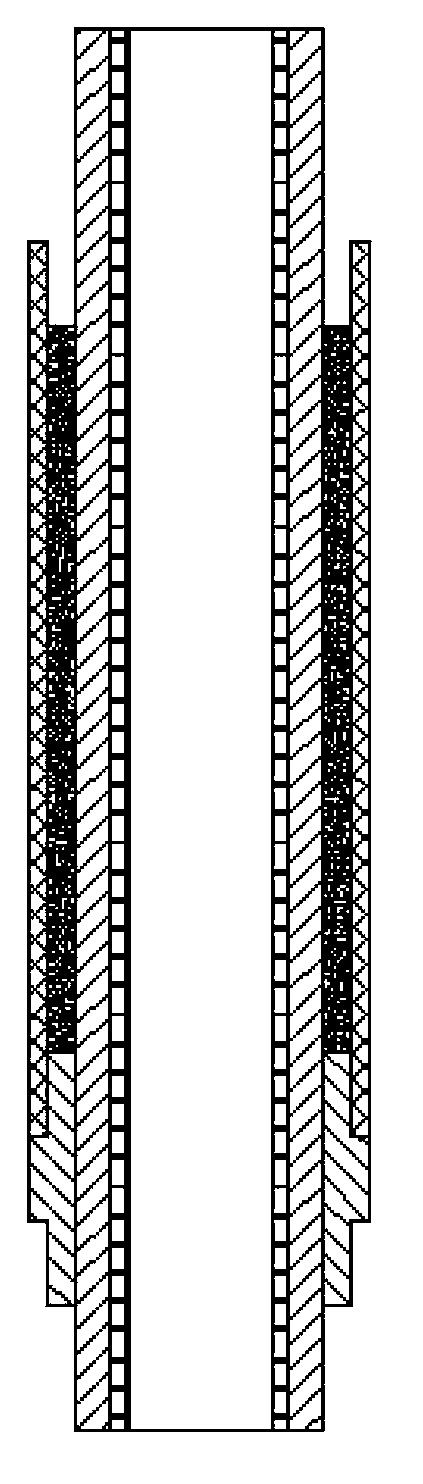

[0028] Such as figure 1 The metal powder tube forming die shown is a preferred embodiment of the present invention, the metal powder tube forming die includes an inner mold 1, an outer mold 2 and a plug 3, the inner mold is sleeved in the outer mold and the two A powder tube molding cavity 4 is formed between them; there are two plugs, which are respectively arranged in the two ports of the powder tube forming cavity formed by the inner mold and the outer mold for sealing the cavity; The mold is a rigid mold made of high temperature resistant glass tube. The inner mold includes a polyur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shore hardness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com