High-speed laser welding method for invar film

A laser welding and laser welding machine technology, applied in laser welding equipment, welding equipment, welding/welding/cutting objects, etc., can solve the problems of difficult connection of invar steel films, increasing temperature gradient, restricting welding speed, etc. The welding process and parameters are easy to control, the welding deformation is reduced, and the structure is simple.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

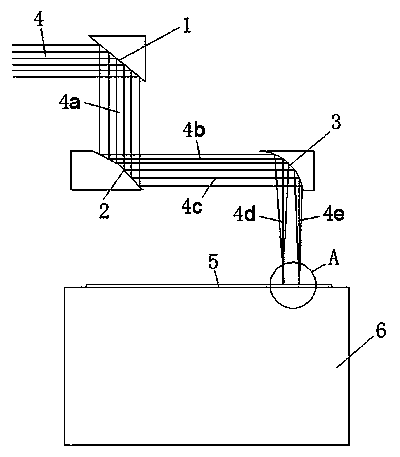

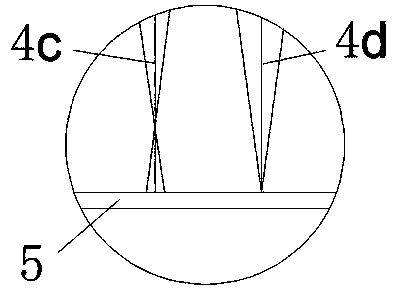

[0024] figure 1 , 2 An optical schematic diagram of high-speed laser welding of Invar steel thin films is shown. In the figure, in the high-speed laser welding method of Invar steel film, the incident laser beam angle of 4 degrees of the laser welding machine is reflected by the angle of 1 degree of the mirror, and the reflected laser beam angle of 1 degree of the mirror is 4a The angle is divided into the first reflected laser beam angle 4b degree and the second reflected laser beam angle 4b degree by the roof-type beam splitter angle 2 degrees, and the first reflected laser beam angle 4b degree is passed through the focusing mirror After focusing at an angle of 3 degrees, a preheating laser beam angle of 4d is formed, and the second reflected laser beam at an angle of 4b is focused by a focusing mirror at an angle of 3 degrees to form a welding laser beam at an angle of 4e, and the preheating laser The beam angle of 4d degrees and the welding laser beam angle of 4e degrees...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com