Method for lowering hot cracking tendency of invar welding through layered pulse lasers

A pulsed laser and laser technology, applied in laser welding equipment, welding equipment, welding/welding/cutting items, etc., can solve the problems of reducing welding stress and thermal cracks of invar steel laser welding, and achieve a wide range of options and reduce Welding temperature gradient, post-weld cooling rate, and parameter design are convenient and flexible

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

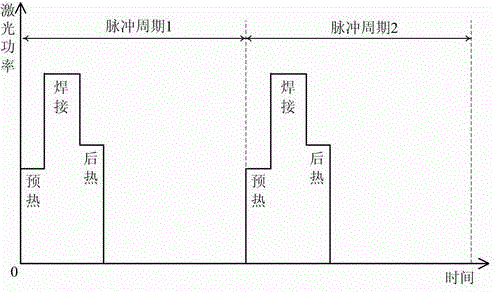

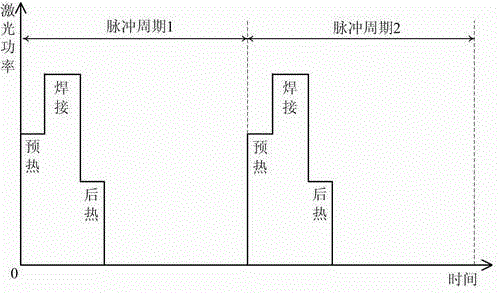

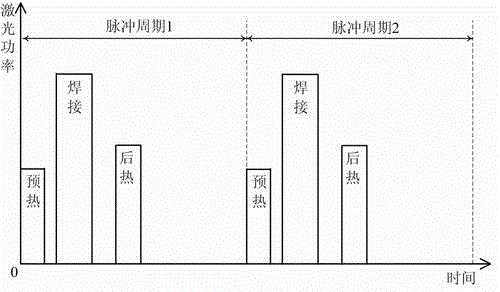

[0034] figure 1 Indicates layered pulsed laser scheme 1:

[0035] (1) Clean the joint surface of the cut invar steel specimen with ethanol, then rinse it with water and blow it dry with a fan, put it into the fixture of the welding workbench, and fix it with laser spot welding at the beginning and end of the weld, To prevent misalignment deformation during welding;

[0036] (2) Adjust the distance between the height of the laser welding head and the surface of the invar steel specimen to be 80-100mm, the positive defocus of the laser is 3-8mm, and adjust the distance between the shielding gas nozzle and the surface of the invar steel specimen to be 45 degrees at a distance of 10-15mm Corner, protective gas flow 10-15L / min;

[0037] (3) Set layered pulse laser energy separately, preheating laser power 100-240 watts, pulse width 0.5-3ms, welding laser power 300-550 watts, pulse width 2-5ms, post-welding thermal laser power 80-150 watts , the pulse width is 0.5-3ms, there is n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com