Backfill for checking peripheral settlement of wells and pipelines and preparation method of backfill

An inspection well and backfill technology, applied in the field of civil engineering, can solve the problems that the test index is difficult to meet the requirements of the design specification, the backfill part cannot be connected, the construction process is complicated, etc., and achieves broad application and promotion prospects, and has significant economic and social benefits. , the effect of simple construction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

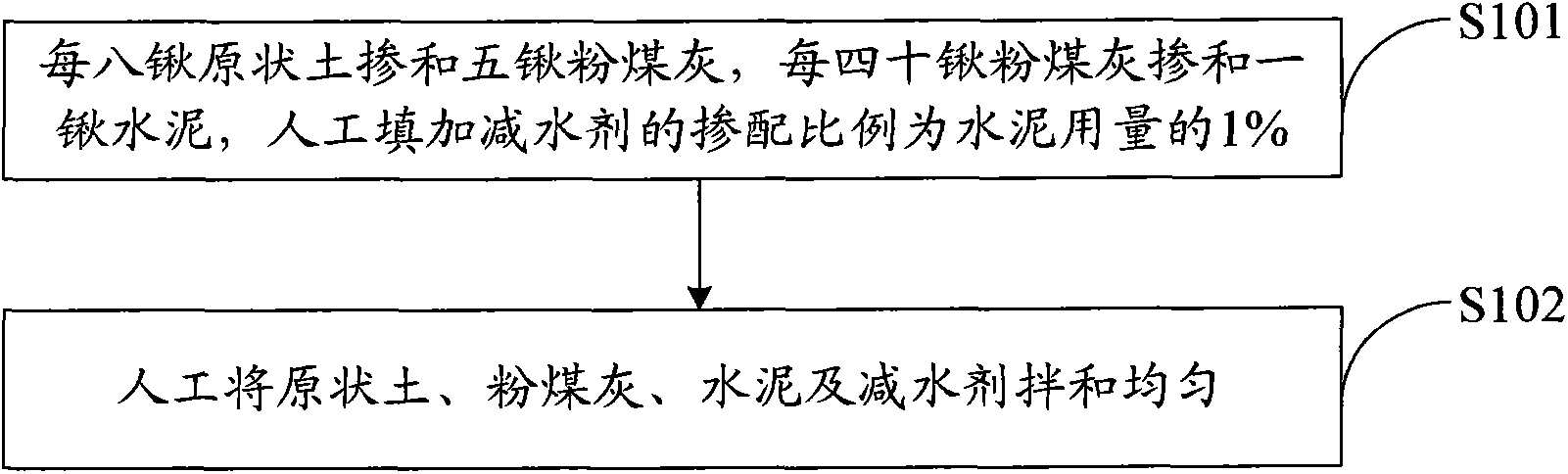

[0038] The preparation method of the backfill used for checking the settlement around the well and pipeline comprises the following steps:

[0039] Step S101, mixing five shovels of fly ash for every eight shovels of undisturbed soil, and one shovel of cement for every 40 shovels of fly ash, and the blending ratio of manually adding a water reducing agent is 1% of the amount of cement;

[0040] Step S102, manually mixing the undisturbed soil, fly ash, cement and water reducer evenly.

[0041] In the embodiment of the present invention, the over-wet fly ash should be air-dried, and the over-dried fly ash should be watered and stuffed 2-3 days before mixing, and the water content should be adjusted to 5% higher than the optimum water content range ~10%, the water content during construction should be 3%~5% higher than the optimal water content.

[0042] In the embodiment of the present invention, when manually blending, it is necessary to use a shovel and a bucket to cooperate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com