Method for purifying phosphorylated eledoisin

A technology of muscarin and a purification method, which is applied in the field of chemical purification, can solve the problem of inability to purify a large number of phosphorylated polypeptides and the like, and achieves the effects of good purification, economical efficiency and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

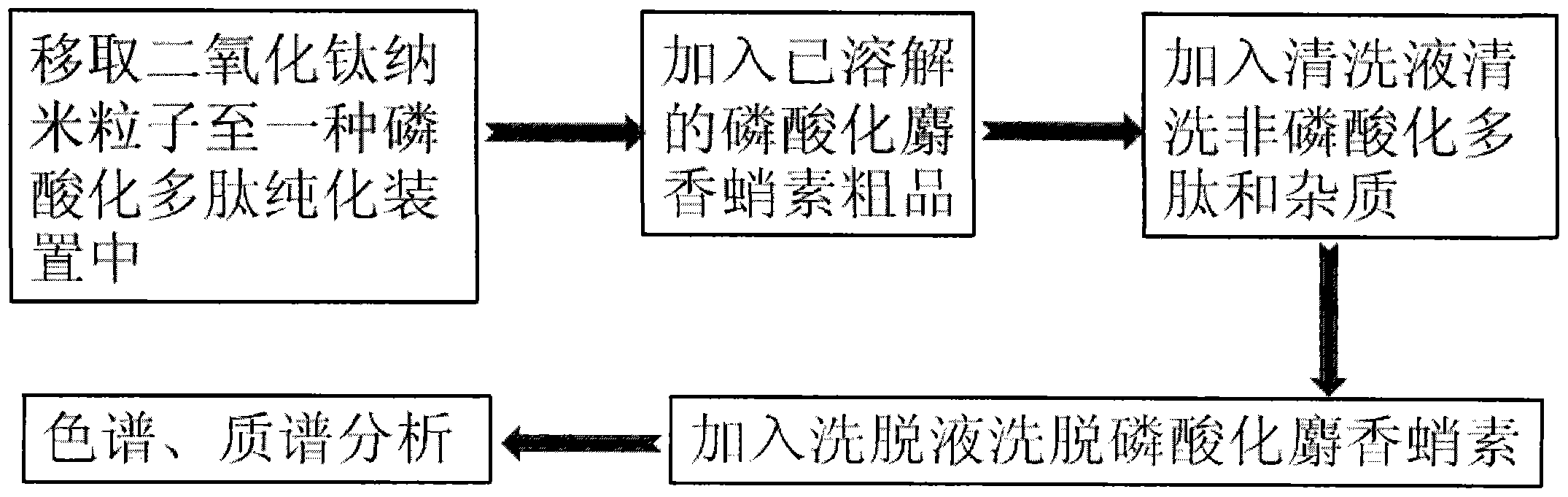

Method used

Image

Examples

Embodiment 1

[0027] Purification of a simple sample of phosphorylated muscotin mixed with two other non-phosphopeptides:

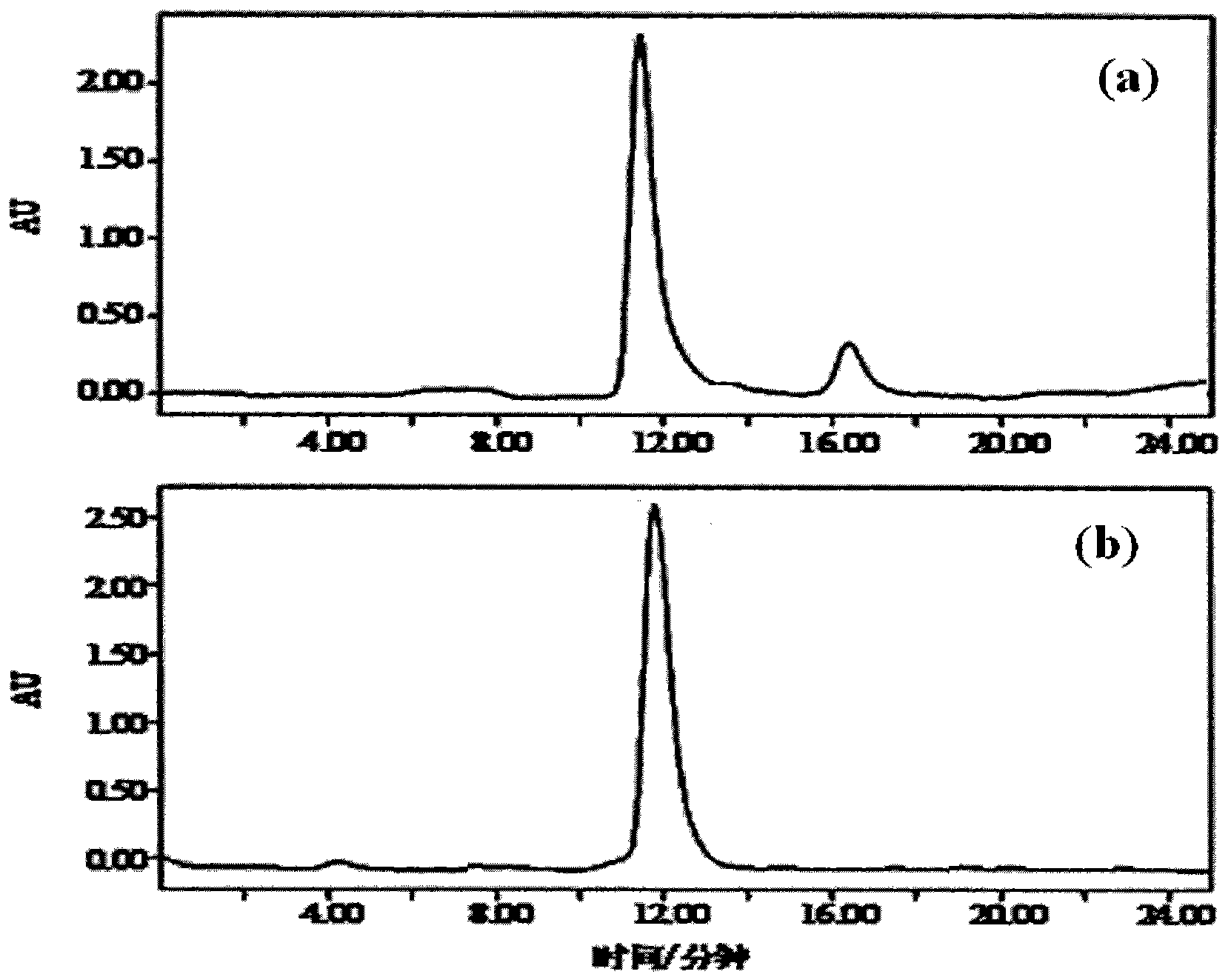

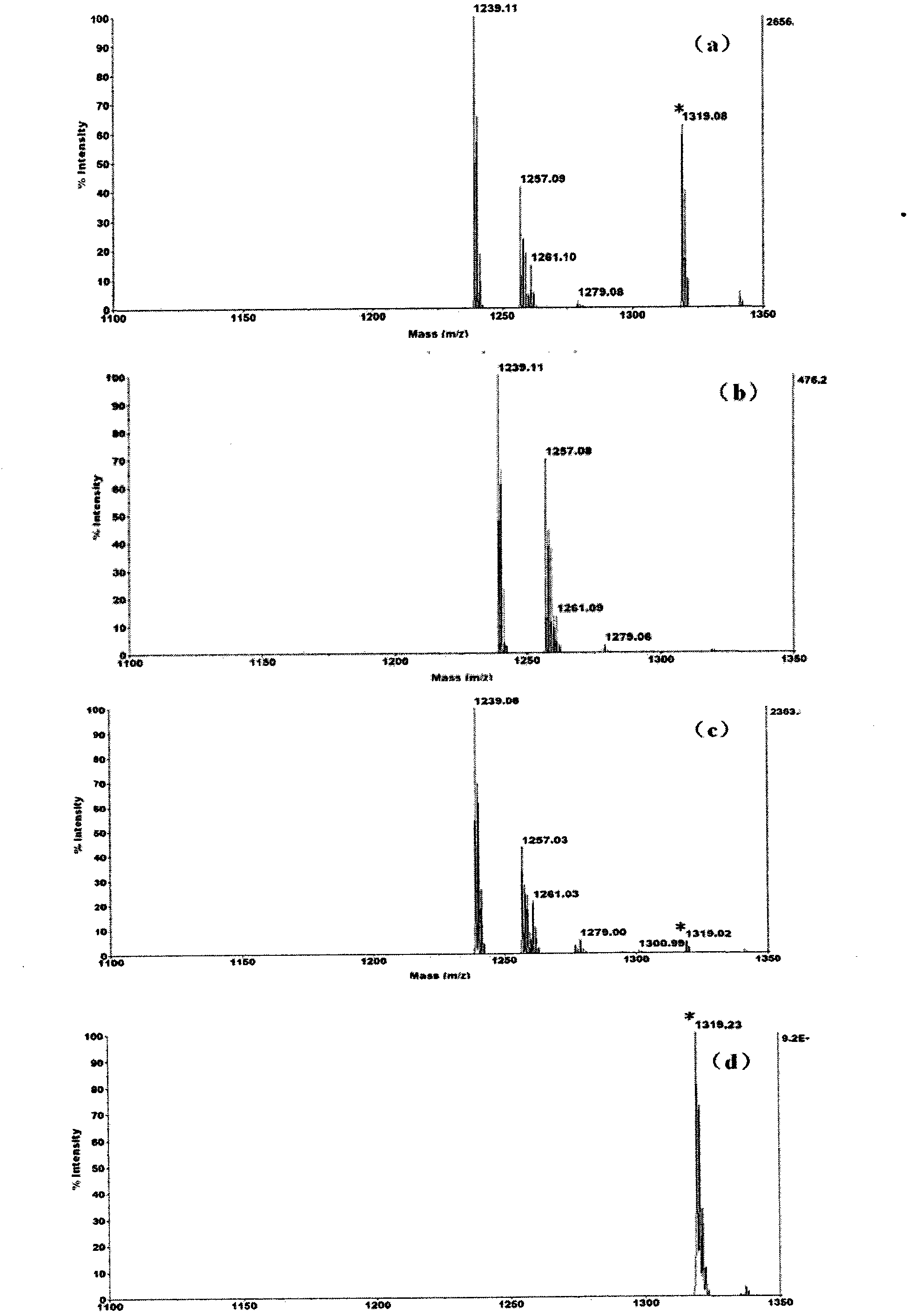

[0028]Weigh 100 mg of titanium dioxide into a purified glass tube with a sieve plate, add 10 mL of 70% acetonitrile / 3% TFA solution, shake up and down for 1 minute, filter the solution under reduced pressure at 0.05-0.09 mbar, and wait for the sample; weigh the pure product of phosphorylated polypeptide 1 Pyr-Pro-Ser-Lys-Asp-Ala-Phe-Tyr (PO 3 H)-Gly-Leu-Met-NH 2 and two pure non-phosphorylated polypeptides [Pyr-Pro-Ser-Lys-Asp-Ala-Phe-Phe(Cl)-Gly-Leu-Met-NH 2 and Pyr-Pro-Ser-Lys-Asp-Ala-Phe-Tyr-Gly-Leu-Met-NH 2 ] each 10 mg, after mixing, dissolve in 20 mL of 70% acetonitrile / 3% TFA solution, oscillate up and down for 5 minutes, filter the solution under reduced pressure at 0.05-0.09 mbar; add 60% acetonitrile / 0.1% TFA 20mL of the solution, shake up and down for 1 minute, filter the solution under reduced pressure; add 20mL of the solution of 50% acetonitrile / 0.1% T...

Embodiment 2

[0030] Purification and preparation of phosphorylated muscotin chemically synthesized by monomer method:

[0031] Weigh 1 g of titanium dioxide into a purified glass tube with a sieve plate, add 10 mL of a solution of 70% acetonitrile / 3% TFA, shake up and down for 1 minute, filter the solution under reduced pressure at 0.05-0.09 mbar, and wait for Loading the sample; Weigh the phosphorylated muscarin [Pyr-Pro-Ser(PO 3 H)-Lys-Asp-Ala-Phe-Ile-Gly-Leu-Met-NH 2 ] Crude product, dissolve it in 20mL of a solution of 70% acetonitrile / 3% TFA, shake it up and down for 5 minutes, filter the solution under reduced pressure at 0.05-0.09mbar; add a solution of 60% acetonitrile / 0.1% TFA 20mL, oscillate up and down for 1 minute, filter the solution under reduced pressure at 0.05-0.09mbar; add 20mL of 50% acetonitrile / 0.1% TFA solution, oscillate up and down for 1 minute, filter the solution under reduced pressure; add 20mL of 50% acetonitrile solution, shake up and down for 1 minute, filte...

Embodiment 3

[0033] Purification and preparation of phosphorylated muscotin chemically synthesized by overall method:

[0034] Weigh 1 g of titanium dioxide into a purified glass tube with a sieve plate, add 10 mL of a solution of 70% acetonitrile / 3% TFA, shake up and down for 1 minute, filter the solution under reduced pressure at 0.05-0.09 mbar, and wait for Sample loading; Weigh the phosphorylated muscarin [Pyr-Pro-Ser(PO 3 H)-Lys-Asp-Ala-Phe-Ile-Gly-Leu-Met-NH 2 ] Crude product, dissolve it in 20mL of a solution of 70% acetonitrile / 3% TFA, shake it up and down for 5 minutes, filter the solution under reduced pressure at 0.05-0.09mbar; add a solution of 60% acetonitrile / 0.1% TFA 20mL, shake up and down for 1 minute, filter the solution under reduced pressure at 0.05-0.09mbar; add 20mL of 50% acetonitrile / 0.1%TFA solution, shake up and down for 1 minute, and filter the solution at Filter under reduced pressure; add 20mL of 50% acetonitrile solution, shake up and down for 1 minute, filt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com