A kind of preparation method of antibacterial protein peptide-nanoparticle complex

A protein peptide and nanoparticle technology, which is applied in the preparation method of peptides, antibacterial drugs, hydrolyzed protein components, etc., can solve problems such as behavioral differences, and achieve the effects of reducing toxicity, benefiting health, and improving solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A preparation method of antibacterial protein peptide-nanoparticle complex, specific preparation steps:

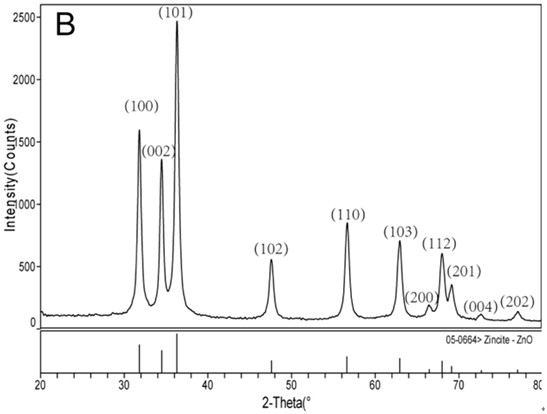

[0024] 1) Preparation of zinc oxide colloid: Add zinc acetate to absolute ethanol, and ultrasonically aid in dissolution to obtain zinc acetate ethanol solution. The concentration of zinc acetate ethanol solution is 0.08-0.12mol / L. Ethanol evaporates. Stir, add sodium hydroxide ethanol solution dropwise to zinc acetate ethanol solution, the concentration of sodium hydroxide ethanol solution is 0.16~0.24mol / L, the volume ratio of sodium hydroxide ethanol solution: sodium hydroxide ethanol solution is 1:0.8~ 1.3, the temperature of the water bath is 75-90°C, shake and stir for 1.5-3 hours, hydrolyze the zinc acetate, sol, and gel to obtain a zinc oxide colloidal solution;

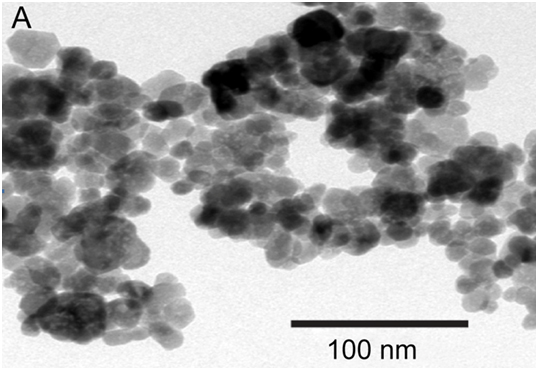

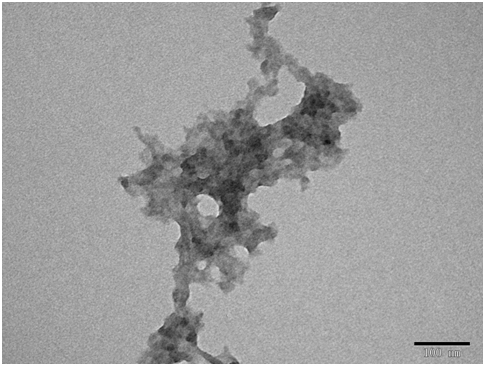

[0025] 2) Preparation of nano-zinc material: add n-hexane and ethylene glycol monomethyl ether to the colloidal solution, n-hexane: colloidal solution volume ratio is 1:0.6-1.5, ethylene glycol mo...

Embodiment 2

[0028] A method for preparing an antibacterial protein peptide-nanoparticle complex, the most preferred preparation steps:

[0029] 1) Preparation of zinc oxide colloid: add zinc acetate to absolute ethanol, and ultrasonically aid in dissolution to obtain zinc acetate ethanol solution, the concentration of zinc acetate ethanol solution is 0.1mol / L, and it is prepared in a closed container to prevent ethanol volatilization . Stir, add the sodium hydroxide ethanol solution dropwise to the zinc acetate ethanol solution, the concentration of the sodium hydroxide ethanol solution is 0.2mol / L, the volume ratio of the zinc acetate ethanol solution:sodium hydroxide ethanol solution is 1:1, and the water bath temperature is 80°C, shaking and stirring for 2 hours, zinc acetate hydrolysis, sol, gel to obtain zinc oxide colloidal solution;

[0030]2) Preparation of nano-zinc material: add n-hexane and ethylene glycol monomethyl ether to the colloidal solution, n-hexane: colloidal solutio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com