Halogen-free flame retardant nylon 6 with high heat resistance as well as preparation method and application thereof

A flame retardant nylon, high heat resistance technology, applied in the field of modified plastics, can solve the problems of low flame retardant efficiency of halogen-free flame retardants, poor mechanical properties of materials, poor compatibility of nylon 6, etc. Water absorption, good synergistic flame retardant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

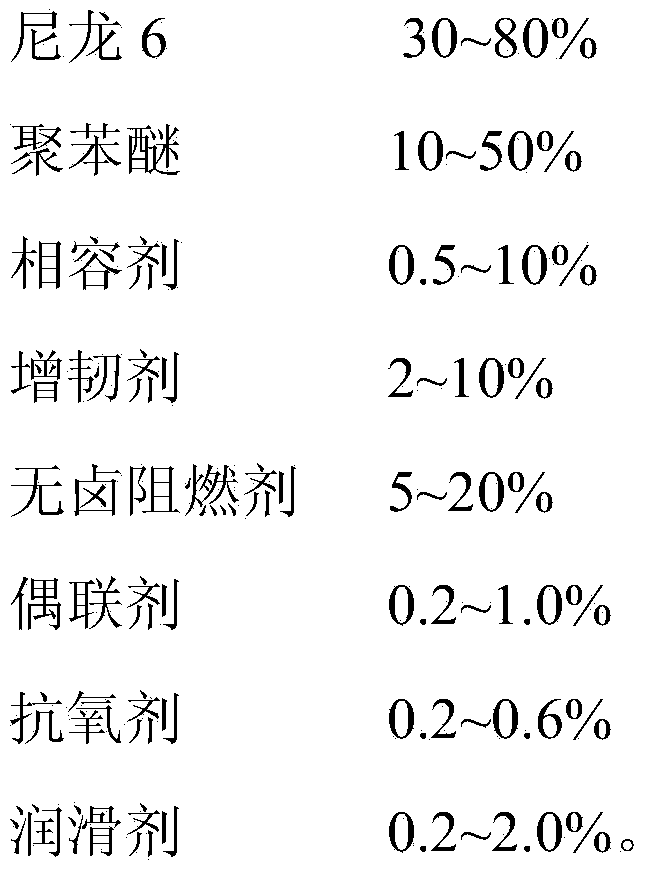

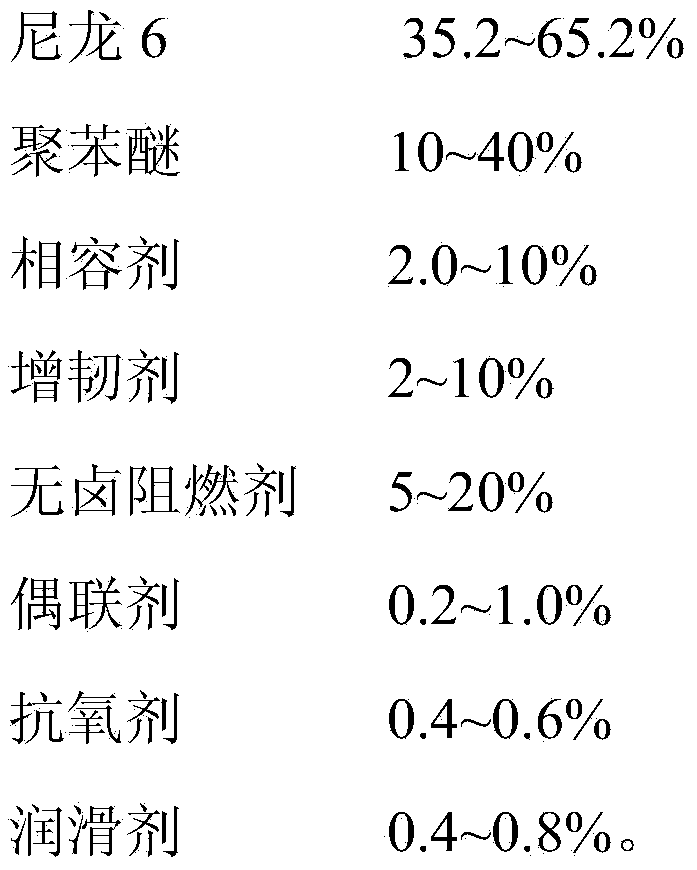

Method used

Image

Examples

Embodiment 1

[0044] A preparation method of high heat-resistant halogen-free flame-retardant nylon 6, comprising the following steps:

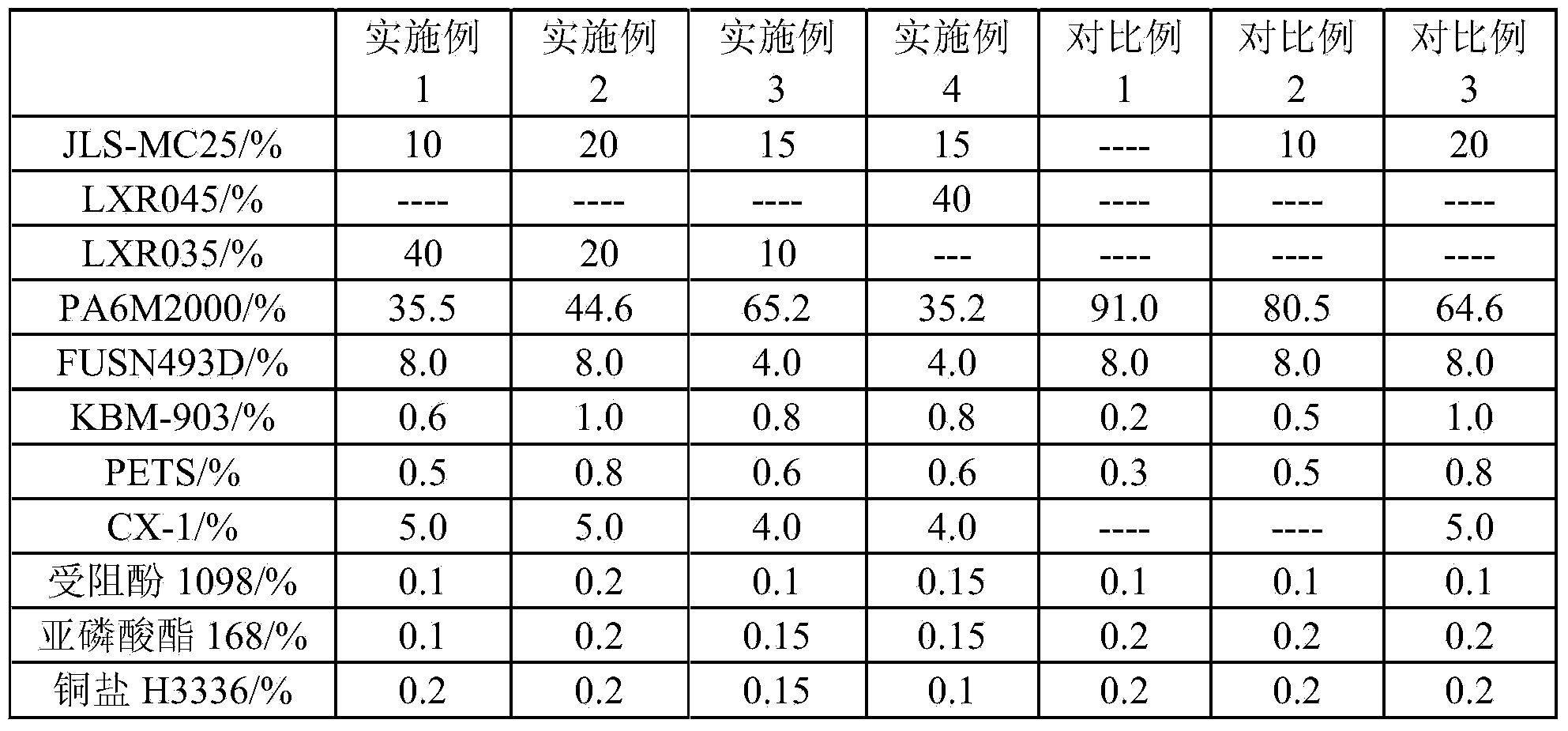

[0045] (1) Weigh raw materials according to the amount of coupling agent, halogen-free flame retardant, nylon 6, polyphenylene ether, compatibilizer, toughening agent, antioxidant and lubricant in Table 1;

[0046] (2) Mix the coupling agent and halogen-free flame retardant at 80°C for 5 minutes, then add nylon 6, polyphenylene ether, compatibilizer, toughener, antioxidant and lubricant and mix at 60°C for 5 minutes, Finally, the mixed material is extruded and granulated by a twin-screw extruder to obtain the high heat-resistant halogen-free flame-retardant nylon 6;

[0047] Wherein the rotational speed of the twin-screw extruder is 500r / min, and the temperature is 220°C. The performance test of the obtained high heat-resistant halogen-free flame-retardant nylon 6 is shown in Table 3.

Embodiment 2

[0049] A preparation method of high heat-resistant halogen-free flame-retardant nylon 6, comprising the following steps:

[0050] (1) Weigh raw materials according to the amount of coupling agent, halogen-free flame retardant, nylon 6, polyphenylene ether, compatibilizer, toughening agent, antioxidant and lubricant in Table 1;

[0051] (2) Mix the coupling agent and the halogen-free flame retardant at 100°C for 4 minutes, then add nylon 6, polyphenylene ether, compatibilizer, toughener, antioxidant and lubricant and mix at 80°C for 4 minutes, Finally, the mixed material is extruded and granulated by a twin-screw extruder to obtain the high heat-resistant halogen-free flame-retardant nylon 6;

[0052] Wherein the rotational speed of the twin-screw extruder is 300r / min, and the temperature is 260°C. The performance test of the obtained high heat-resistant halogen-free flame-retardant nylon 6 is shown in Table 3.

Embodiment 3

[0054] A preparation method of high heat-resistant halogen-free flame-retardant nylon 6, comprising the following steps:

[0055] (1) Weigh raw materials according to the amount of coupling agent, halogen-free flame retardant, nylon 6, polyphenylene ether, compatibilizer, toughening agent, antioxidant and lubricant in Table 1;

[0056] (2) Mix the coupling agent and halogen-free flame retardant at 90°C for 3 minutes, then add nylon 6, polyphenylene ether, compatibilizer, toughener, antioxidant and lubricant and mix at 70°C for 3 minutes, Finally, the mixed material is extruded and granulated by a twin-screw extruder to obtain the high heat-resistant halogen-free flame-retardant nylon 6;

[0057] Wherein the rotational speed of the twin-screw extruder is 200r / min, and the temperature is 280°C. The performance test of the obtained high heat-resistant halogen-free flame-retardant nylon 6 is shown in Table 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com