Rotary variable-frequency vibrating-compacting leaven making machine

A rotary type and koji technology, applied in the field of rotary vibrating forming koji machines and koji forming machines, can solve the problems of low work efficiency, poor production environment, high labor intensity of manual koji making, etc. The effect of demoulding, easy to promote and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

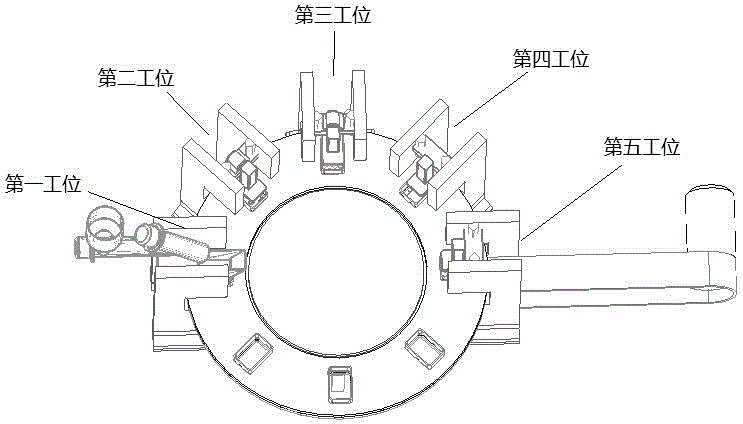

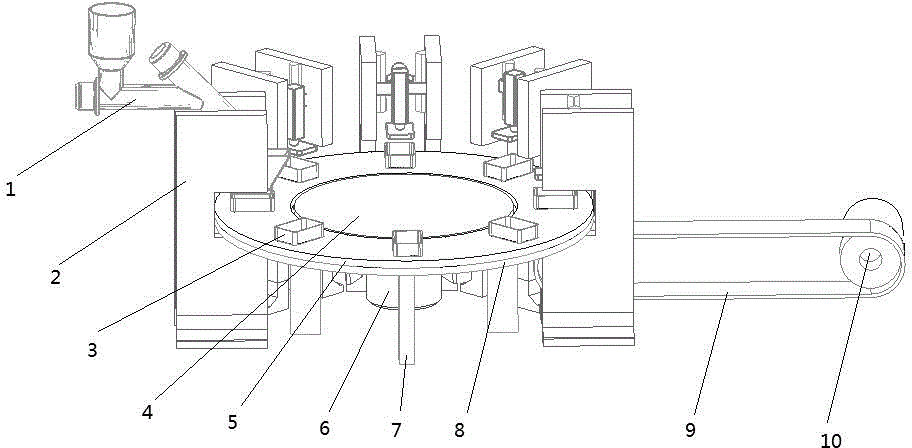

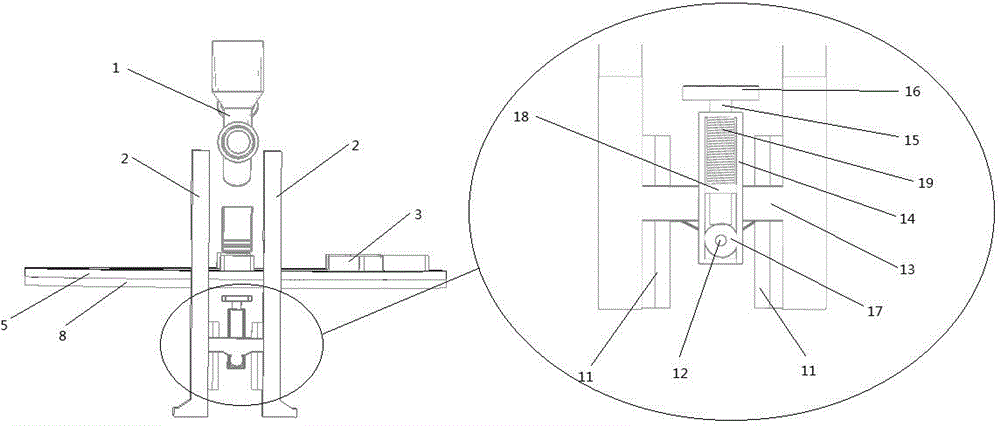

[0030] like Figure 1-13As shown, eight phases are evenly arranged on the circumference of the workbench, and the vibration feeding mechanism, the low-frequency vibration pressure mechanism, the beating pulp lifting mechanism, and the billet shaping mechanism are respectively installed in sequence on the adjacent five consecutive phases through the bracket 2. The control cabinet is connected with the billet discharging mechanism, the vibration feeding mechanism, the low-frequency vibration pressing mechanism, the beating pulp lifting mechanism, the billet shaping mechanism and the billet discharging mechanism to form a rotary frequency conversion vibrating and pressing koji machine; the workbench It includes a rotary disc 5, a rotary motor 6, a frame 7 and a sealing disc 8, a rotary motor 6 is installed longitudinally in the center of the frame 7, a transmission gear 4 is installed on the output shaft of the rotary motor 6, and the driving gear 4 and the rotary disc 5 are drive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com