Method and device for synthesizing ammonia from nitrogen with high-efficiency electrocatalytic reduction at low temperature and normal pressure

An atmospheric voltage, ammonia synthesis technology, applied in electrodes, electrolysis processes, electrolysis components, etc., can solve the problems of low catalytic efficiency of cathode catalysts, and achieve the effect of low speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Hereinafter, the present invention will be further described in detail through specific embodiments in conjunction with the accompanying drawings.

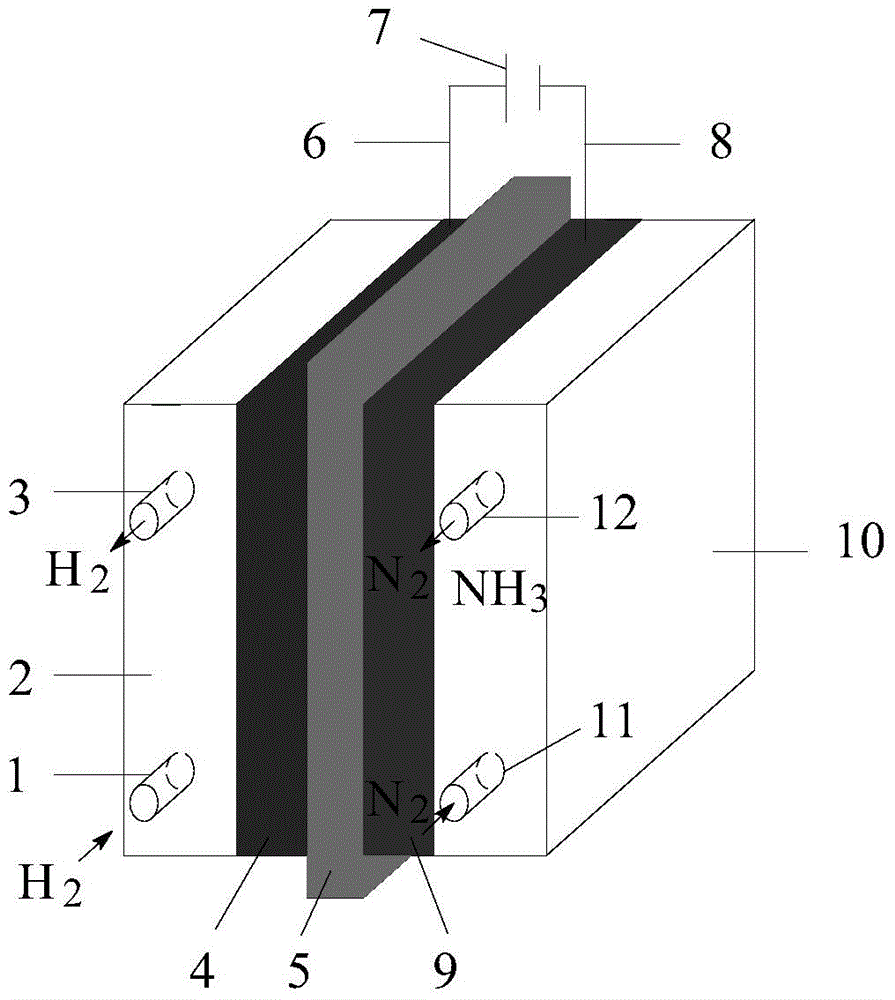

[0030] Fig. 1 is a schematic diagram of the device for the synthesis of ammonia by electrocatalytic reduction of nitrogen at low temperature and atmospheric pressure according to the present invention. In this embodiment, the method for synthesizing ammonia by high-efficiency electrocatalytic reduction of nitrogen at low temperature and normal pressure is specifically operated in the following order and steps:

[0031] (1) Construction of electrolytic cell

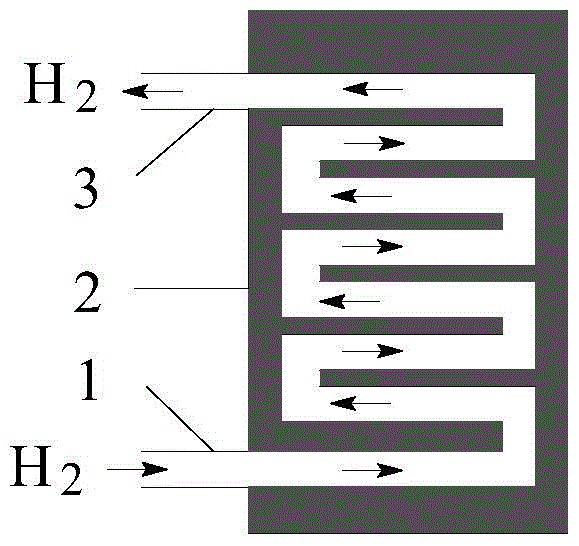

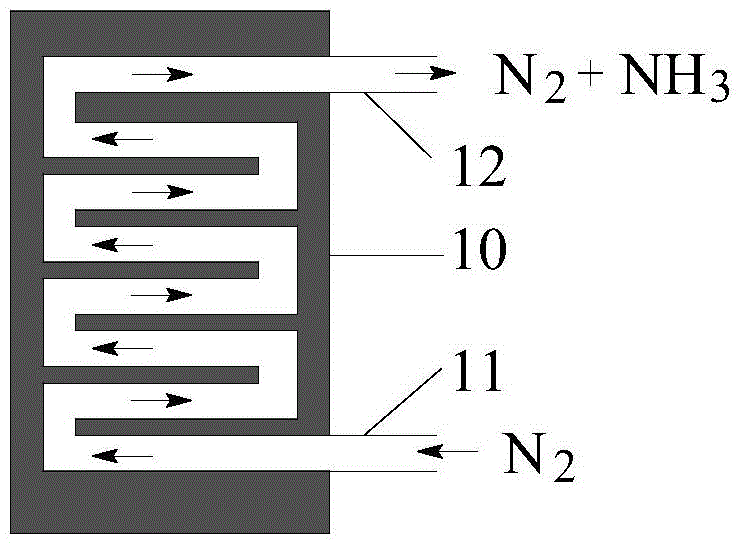

[0032] The electrolytic cell includes: air guide tube 1, anode copper collector plate 2, air guide tube 3, anode electrode 4, proton exchange membrane 5, wire 6, regulated power supply 7, wire 8, cathode electrode 9, cathode copper collector plate 10, The air guide pipe 11 and the air guide pipe 12; the anode copper collector plate 2 has a diversion groove, as the anod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com