Early warning and sampling concrete surface elevation controller

A technology of controller and concrete surface, which is applied in the direction of basic structure test, construction, mechanical depth measurement, etc., can solve the problems of relatively large temperature influence, easy hanging of cages, failure to send signals, etc., to prevent weather factors, good Effects, making and using simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

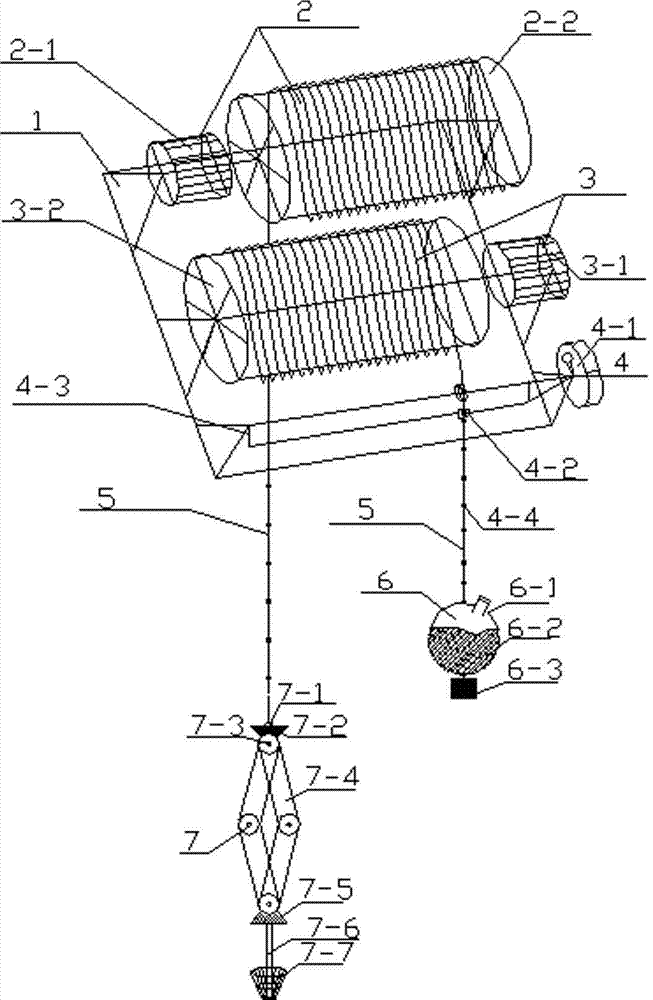

[0023] The early warning and pattern-taking concrete surface elevation controller of the present invention comprises: a controller base frame 1 on which a sampling device and an early warning device are installed.

[0024] The sampling device is composed of a first hoisting mechanism 2 , a measuring rope 5 and a concrete sampling device 7 , and the first hoisting mechanism 2 is connected to the concrete sampling device 7 through the measuring rope 5 .

[0025] The early warning device is composed of a second hoisting mechanism 3, an alarm bell system 4, a measuring rope 5 and a concrete surface suspension device 6, the second hoisting mechanism 3 is connected to the concrete surface suspension device 6 through the measuring rope 5, and the alarm bell system 4 is connected in series Installed on the measuring rope 5.

[0026] The first hoisting mechanism 2 includes: a first motor 2-1, and a first capstan 2-2 connected and driven by the first motor 2-1.

[0027] The second hois...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com