Method for applying gas-soluble surfactant to fluidity control of carbon dioxide oil displacement

A surfactant and carbon dioxide technology, applied in the fields of fluid production, earthwork drilling, wellbore/well components, etc., can solve the problems of inability to inject foaming agent solution, control the mobility of carbon dioxide, gas-liquid separation, etc. Regeneration performance, low price, and the effect of fluidity control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The fatty alcohol polyoxyethylene polyoxypropylene ether described in embodiment 1, embodiment 2, embodiment 3 and embodiment 5~9 is purchased from U.S. Dow Chemical Company, and structural formula is as follows:

[0038]

[0039] Among them: m=5~15, n=4~5.

Embodiment 4

[0040] The nonylphenol polyoxyethylene ether described in embodiment 4 is purchased from the U.S. Dow Chemical Company, and its structural formula is as follows:

[0041]

[0042] Among them: n=5~25.

[0043] Example 1

[0044] A kind of method that aerosol surfactant is used in the fluidity control of carbon dioxide flooding, the steps are as follows:

[0045]Mix fatty alcohol polyoxyethylene polyoxypropylene ether with supercritical carbon dioxide at a mass percentage of 0.3%, the pressure during mixing is 10MPa, and the temperature is 50°C, and then inject it into low-permeability reservoirs according to the existing conventional technology.

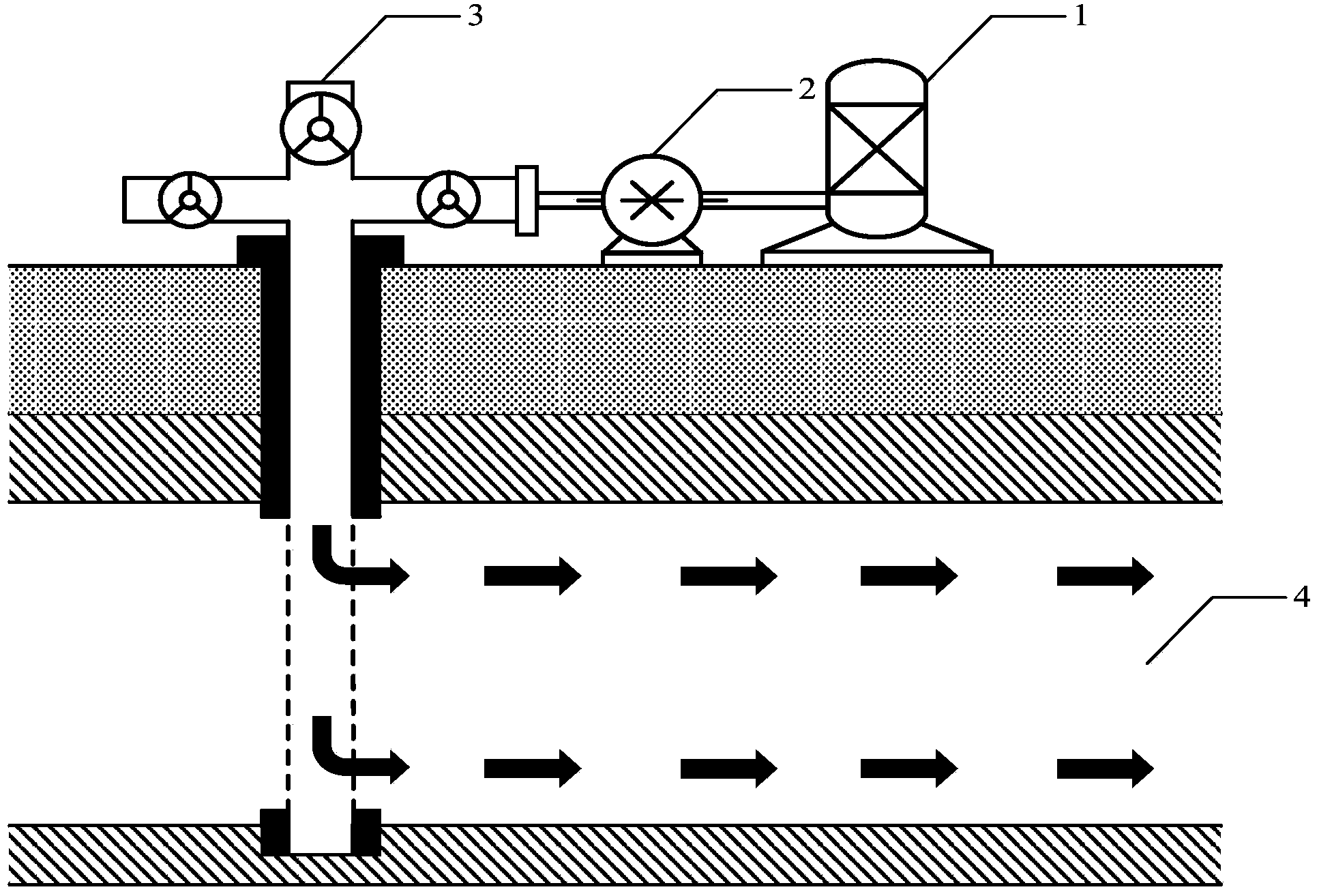

[0046] figure 1 It is a flow control flow chart of carbon dioxide flooding mobility control in low-permeability reservoirs implementing the method of this embodiment, including: high-pressure storage tanks 1 , surface injection facilities 2 , injection wells 3 , and low-permeability reservoirs 4 . Dissolve the fatty alcohol poly...

Embodiment 2

[0049] A kind of method that aerosol surfactant is used in the fluidity control of carbon dioxide flooding, the steps are as follows:

[0050] Mix the fatty alcohol polyoxyethylene polyoxypropylene ether and water at a volume percentage of 0.5% at normal temperature and pressure to obtain an air-soluble surfactant solution; then alternately mix the air-soluble surfactant solution with supercritical carbon dioxide They were respectively injected into low-permeability reservoirs, and the injection mass ratio of fatty alcohol polyoxyethylene polyoxypropylene ether to supercritical carbon dioxide was 1:2.

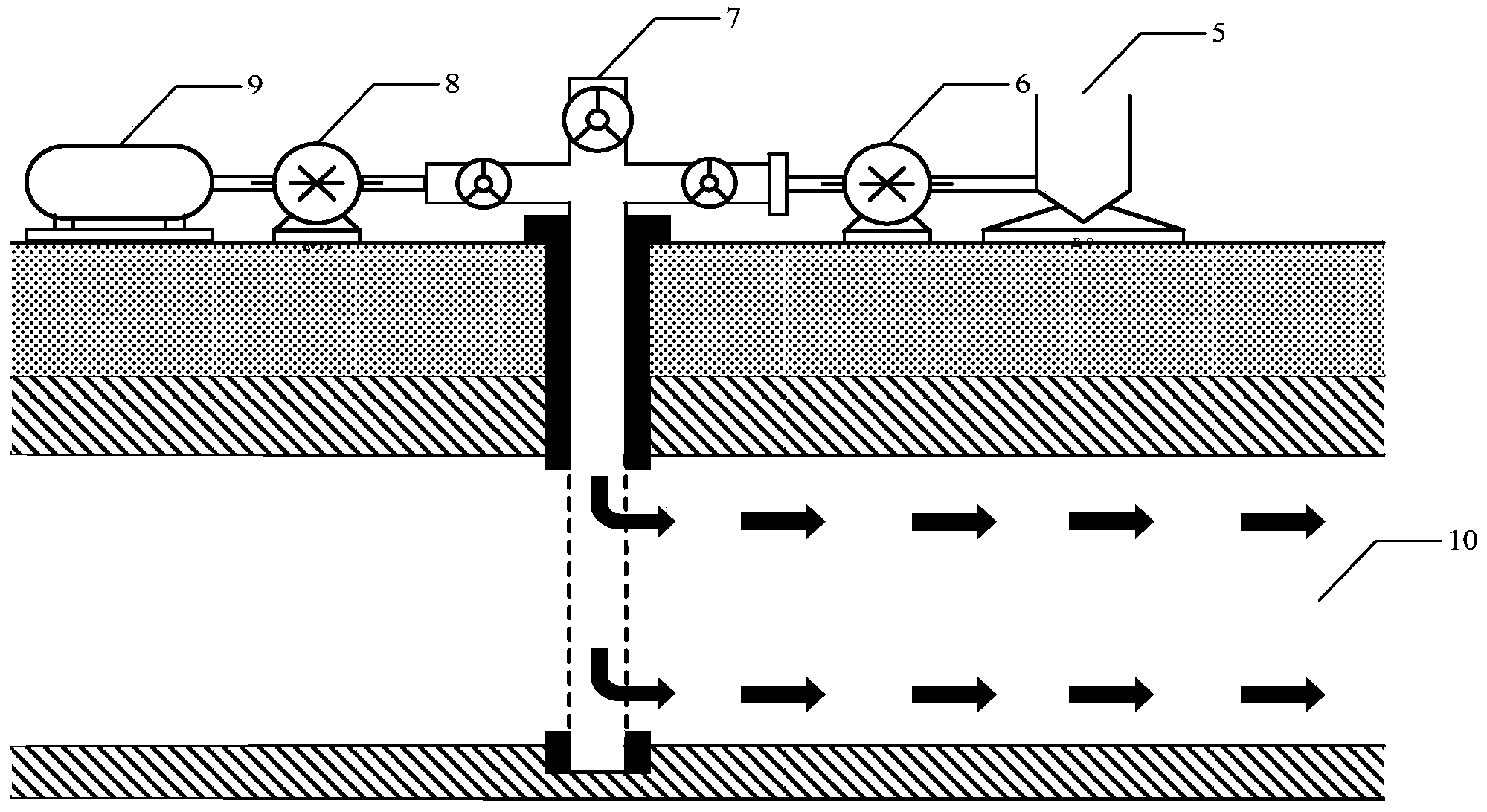

[0051] figure 2 It is a flow control flow chart of carbon dioxide flooding fluidity control in ordinary permeability reservoirs implementing the method of this embodiment, including: water storage tank 5, ground injection facility 6, injection well 7, ground injection facility 8, high-pressure storage tank 9, and oil reservoir 10; Dissolve the fatty alcohol polyoxyethylene po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Permeability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com