High-temperature waste heat recovery machine and process for screw type air compressor

A waste heat recovery and air compressor technology, applied in the direction of machines/engines, mechanical equipment, indirect heat exchangers, etc., can solve the problem that affects the promotion and utilization of waste heat recovery of screw air compressors. Water and other issues, to meet the high-quality heat dissipation requirements, reasonable structure, the effect of expanding the use of space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

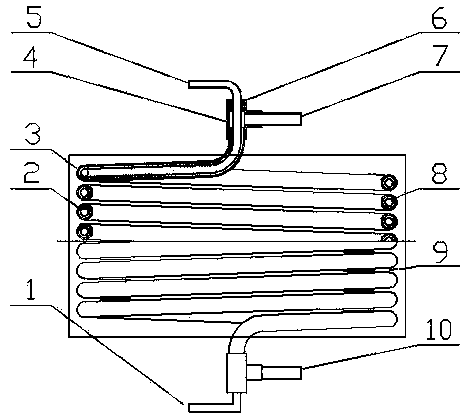

[0033] Such as figure 1As shown, a screw air compressor high temperature waste heat recovery machine, the waste heat recovery machine has a tube heat exchanger connected with the screw air compressor; the tube heat exchanger has an inner tube coaxially arranged 2 and the composite tube composed of the outer tube 3; in this embodiment, the inner tube 2 is a copper tube made of high thermal conductivity metal material, which is in a spiral shape; the outer tube 3 is made of aluminum plastic with a diameter larger tube, first make the copper tube as the inner tube and the aluminum-plastic tube as the outer tube into an equivalent disk-shaped spiral tube, and the inner wall of the outer tube has a plurality of inwardly protruding support points 8 for Support the inner tube and set the inner tube and the outer tube coaxially, and increase the local turbulence effect of the tap water in the flow, thereby increasing the heat exchange effect; then screw the copper tube into the alumin...

Embodiment 2

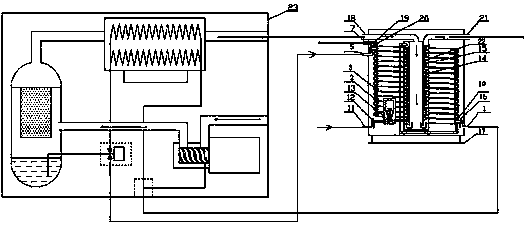

[0039] Since the high-temperature oil of the screw air compressor accounts for 75% of the total waste heat of the machine, and the high-temperature compressed air accounts for 25% of the total waste heat, and embodiment 1 only completes the heat exchange between the high-temperature oil of the screw air compressor and tap water, in order to further improve The temperature of tap water. In this embodiment, the tap water inlet 10 of the tube heat exchanger communicates with the tap water pipe through the gas-liquid heat exchanger I. The gas-liquid heat exchanger I is used to make the screw air compressor The high-temperature compressed air exchanges heat with the tap water, so that the tap water is preheated once before entering the tube heat exchanger, which increases the temperature of the tap water, and the high-temperature compressed air of the screw air compressor is discharged after heat exchange and cooling, reducing the loss of heat energy. Loss; The structure of tube hea...

Embodiment 3

[0043] Since the high-temperature oil of the screw air compressor accounts for 75% of the total waste heat of the machine, and the high-temperature compressed air accounts for 25% of the total waste heat, and embodiment 1 only completes the heat exchange between the high-temperature oil of the screw air compressor and tap water, in order to further improve The temperature of the tap water, in this embodiment, through the gas-liquid heat exchanger II designed by the screw air compressor itself, the tap water and the high-temperature compressed air of the screw air compressor are heat-exchanged, so that the tap water can be obtained before entering the tube heat exchanger. One-time preheating increases the temperature of tap water, and discharges the high-temperature compressed air of the screw air compressor after exchanging heat and cooling down, reducing the loss of heat energy; the air-liquid heat exchanger designed by the screw air compressor itself in the prior art The cool...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com