Density determination device for slurry in wet desulfurization absorption tower

A technology of density measurement and wet desulfurization, which is applied in the direction of determining the specific gravity by measuring the pressure difference, which can solve the problems affecting the accuracy of the density calculation value, the distortion of the differential pressure measurement value, and the deviation of the density calculation value, so as to ensure the service life and Detection accuracy, avoidance of wear and scaling problems, effect of unobstructed circulation flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

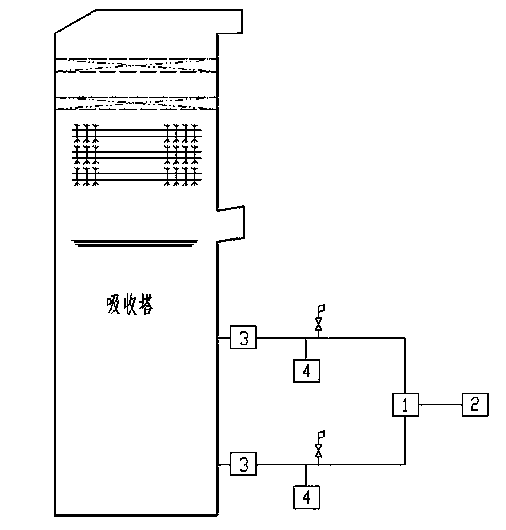

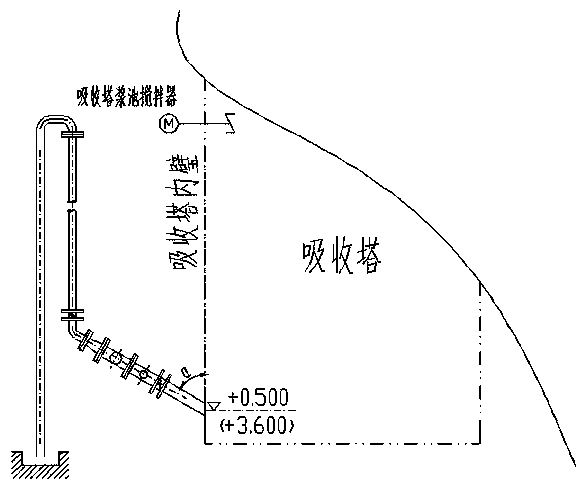

[0032] Implementation cases of this patent: such as figure 1 As shown, it is the measurement device for the density of gypsum slurry in the absorption tower, which is the core equipment for absorbing sulfur dioxide in the wet desulfurization system, mainly including 1-flange-mounted diaphragm differential pressure transmitters (both flanges have equal-length capillaries) ), 2-intelligent calculation controller, 3-measuring sampling pipeline assembly, 4-cleaning and discharging pipeline assembly.

[0033] Continuously monitor the absorption tower through the flange-mounted diaphragm differential pressure transmitter (1) with equal-length capillary tubes on both sides installed at the height of +0.5-1.5m and +1.8m-3.6m above the ground of the absorption tower Static pressure difference of internal gypsum grout. The real-time measured static pressure difference is transmitted to the desulfurization control system through hard wiring with a standard signal of 4-20mA, and displaye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com