Moisturizing nano light-screening agent for toning lotion and preparation method of light-screening agent

A technology for lotion and sunscreen, applied in the field of moisturizing nano sunscreen for lotion and preparation thereof, can solve the problems of skin care without any benefit, large particle size of sunscreen, affecting appearance, etc., and achieves improved stability, The effect of good stability and strong covering power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

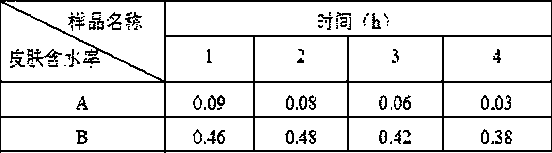

Examples

Embodiment 1

[0020] A method for preparing a moisturizing nano sunscreen for lotion uses the following steps:

[0021] 1): Weigh 16.67g ethanol, 16.67g PPG-26-butanol-26 and 16.66g PEG-20 hydrogenated castor oil and mix, heat to 50°C, mix well to obtain emulsifier;

[0022] 2): Weigh 50g of emulsifier and 50g of diphenyl dimethicone, slowly add oil to the emulsifier under stirring conditions, heat to 60℃, and mix well;

[0023] 3): The mixture obtained in step 1 is homogenized 3 times through a high-pressure homogenizer at a pressure of 5 MPa and a temperature of 60 ℃ at 3500 rpm, and a cooling device is used at the outlet of the high-pressure homogenizer to ensure the temperature of the mixture at the outlet of the high-pressure homogenizer It does not exceed 70°C, and after homogenization is completed, a moisturizing nano sunscreen for lotion with an average particle size of 250 nm can be obtained.

Embodiment 2

[0025] A method for preparing a moisturizing nano sunscreen for lotion uses the following steps:

[0026] 1): Weigh 47.62g of ethanol, 9.52g of PPG-26-butanol-26 and 9.52g of PEG-40 hydrogenated castor oil and mix, heat to 50℃, and mix well to obtain an emulsifier;

[0027] 2): Weigh 66.66g of the emulsifier obtained in step 1 and 33.34g of diphenylsiloxyphenyl trimethicone, add oil to the emulsifier under stirring conditions, heat to 60°C, and mix Evenly

[0028] 3): The mixture obtained in step 2 is homogenized 5 times through a high-pressure homogenizer at a pressure of 20 MPa and a temperature of 60 ℃ at 3500 rpm. A cooling device is used at the outlet of the high-pressure homogenizer to ensure the temperature of the mixture at the outlet of the high-pressure homogenizer. It does not exceed 70°C, and after homogenization is completed, a moisturizing nano-screening agent for lotion with an average particle size of 200 nm can be obtained.

Embodiment 3

[0030] A method for preparing a moisturizing nano sunscreen for lotion uses the following steps:

[0031] 1): Weigh 41.67g of ethanol, 25.0g of PPG-26-butanol-26 and 8.33g of PEG-60 hydrogenated castor oil and mix, heat to 50°C, and mix well to obtain an emulsifier;

[0032] 2): Weigh 75.0g of the emulsifier obtained in step 1 and 25.0g of propylene glycol dibenzoate, slowly add the propylene glycol dibenzoate to the emulsifier under stirring conditions, heat to 60°C, and mix well;

[0033] 3): The mixture obtained in step 2 is homogenized 8 times through a high-pressure homogenizer at a pressure of 30 MPa and a temperature of 60 ℃ at 3500 rpm. A cooling device is used at the outlet of the high-pressure homogenizer to ensure the temperature of the mixture at the outlet of the high-pressure homogenizer. It does not exceed 70°C, and after homogenization is completed, a moisturizing nano-screening agent for lotion with an average particle size of 150nm can be obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com