Aminophylline tablet and preparation method thereof

A technology for aminophylline and alkali tablets, which is applied in the field of aminophylline tablets and its preparation, and can solve the problems of internal quality differences, unstable processes, and large differences in real-time dissolution behaviors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

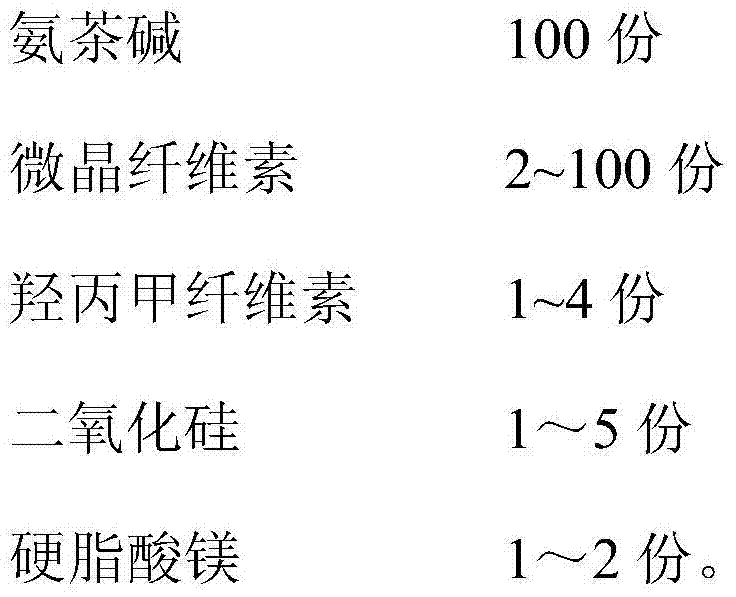

[0044] A kind of aminophylline tablet, comprises following component by weight percentage:

[0045]

[0046]

[0047] A preparation method of aminophylline tablet, comprising the following steps (the amount of each component is as described in Table 1):

[0048] (1) The aminophylline in the weight ratio is crushed and passed through a 65-mesh sieve.

[0049] (2) Take the microcrystalline cellulose, hypromellose and silicon dioxide in the weight ratio and the aminophylline powder, pass through a 65-mesh sieve and mix evenly.

[0050] (3) Add the magnesium stearate in the weight ratio and mix evenly.

[0051] (4) Press the mixed powder on the tablet machine to compress the tablet, and pack the finished product after the tablet is tested and qualified.

Embodiment 2

[0053] A kind of aminophylline tablet, comprises following component by weight percentage:

[0054] components weight Aminophylline 100 g microcrystalline cellulose 100 g hypromellose 1 silica 4 grams Magnesium stearate 2.04 grams

[0055] A preparation method of aminophylline tablet, comprising the following steps (the amount of each component is as described in Table 2):

[0056] (1) The aminophylline in the weight ratio is crushed and passed through a 65-mesh sieve.

[0057] (2) Take the microcrystalline cellulose, hypromellose and silicon dioxide in the weight ratio and the aminophylline powder, pass through a 65-mesh sieve and mix evenly.

[0058] (3) Add the magnesium stearate in the weight ratio and mix evenly.

[0059] (4) Press the mixed powder on the tablet machine to compress the tablet, and pack the finished product after the tablet is tested and qualified.

Embodiment 3

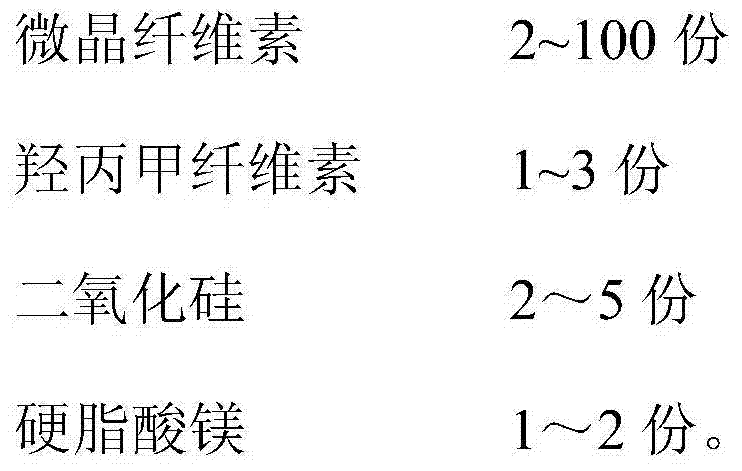

[0061] A kind of aminophylline tablet, comprises following component by weight percentage:

[0062] components weight Aminophylline 100 g microcrystalline cellulose 2 grams hypromellose 4 grams silica 2 grams Magnesium stearate 1 g

[0063] A preparation method of aminophylline tablet, comprising the following steps:

[0064] (1) The aminophylline in the weight ratio is crushed and passed through a 65-mesh sieve.

[0065] (2) Take the microcrystalline cellulose, hypromellose and silicon dioxide in the weight ratio and the aminophylline powder, pass through a 65-mesh sieve and mix evenly.

[0066] (3) Add the magnesium stearate in the weight ratio and mix evenly.

[0067] (4) Press the mixed powder on the tablet machine to compress the tablet, and pack the finished product after the tablet is tested and qualified.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com