Preparation method of tungsten powder for cathodes and application thereof

A technology of tungsten powder and cathode, which is applied in the field of tungsten powder preparation, can solve the problems of non-concentrated particle size distribution, easy water absorption and high impurities of tungsten powder, and achieve the effect of simple method and few steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The preparation method of the tungsten powder used for cathode provided by the present invention, wherein, the method comprises the following steps:

[0031] (1) In a hydrogen atmosphere, heat-treat the tungsten powder and then cool it;

[0032] (2) Ball mill the cooled tungsten powder;

[0033] (3) Screen the tungsten powder after ball milling;

[0034] Wherein, the heat treatment is to raise the temperature of the tungsten powder to 1850-2000° C. at a heating rate of 455-495° C. / min, and keep it at this temperature for 100-140 minutes.

[0035] In the present invention, the tungsten powder is heated to 1850-2000°C at a heating rate of 455-495°C / min for heat treatment in a hydrogen atmosphere, and the oxide layer on the surface of the tungsten powder is reduced under the action of hydrogen to obtain high-purity tungsten powder. The cooled tungsten powder is ball milled and screened to obtain a high-purity tungsten powder with a particle size distribution of 3-5 μm an...

Embodiment 1

[0047]Put lint-free paper on each of the left and right trays of the balance, weigh the tungsten powder, put the tungsten powder into the molybdenum bowl with a horn spoon, and level it out. With the capacity of the molybdenum bowl being 100 parts by volume, the amount of tungsten powder is 20 Parts by volume; then put the molybdenum bowl with tungsten powder into a dry bottle, heat treatment in a tungsten mesh hydrogen furnace, the working atmosphere is hydrogen, and heat up to 1900°C at a heating rate of 470°C / min and keep it for 120min, then cool to 20°C.

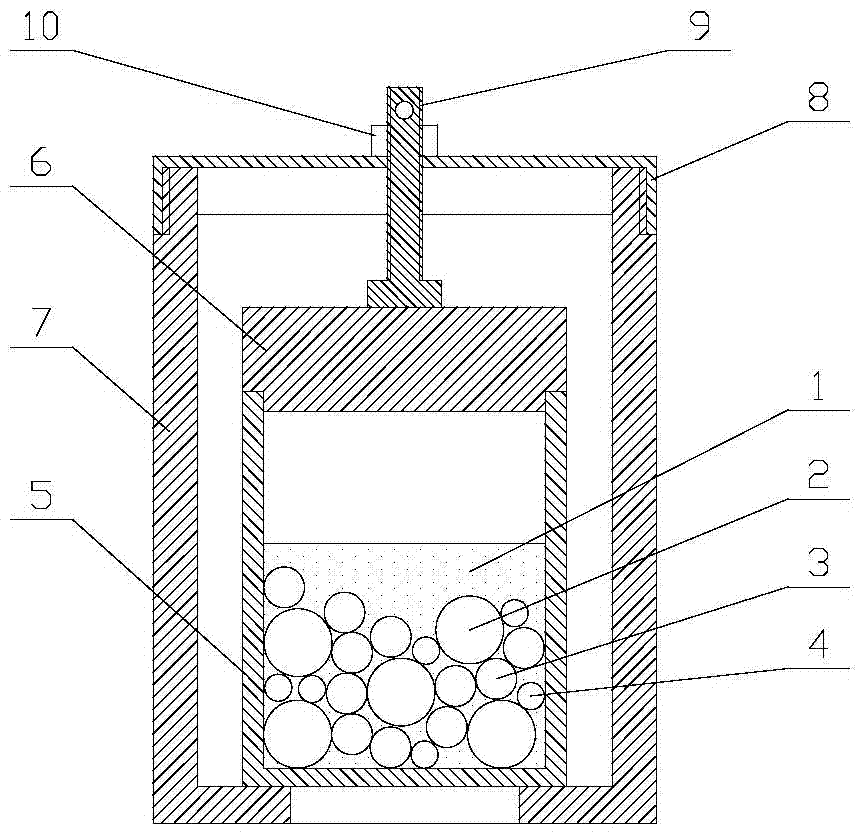

[0048] Put the tungsten powder obtained after high-temperature treatment and cooling in the tungsten mesh hydrogen furnace into an agate bowl, and use an agate rod to crush it into tungsten powder particles with a particle size of 3mm-5mm1. Then if figure 1 As shown, put 250g tungsten powder particles 1, 5 first agate balls 2 of Ф25mm, 11 second agate balls 3 of Ф15mm and 6 third agate balls 4 of Ф10mm into a 0.4L agate...

Embodiment 2

[0052] Carry out according to the method of Example 1, the difference is that the tungsten powder is heated up to 1940°C at a heating rate of 480°C / min in the presence of hydrogen. The tungsten powder obtained in this embodiment is off-white. The particle size and particle distribution of the tungsten powder obtained in this embodiment and the purity of the tungsten powder are detected. It is known that the particle size of the tungsten powder particle is 3-5 μm. The weighted width of particle size is 57.33%, and the purity of tungsten powder is 99.999%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com