Machine tool used for machining gear shaving cutter chip pocket

A chip flute and shaving cutter technology, which is applied in the direction of metal processing machinery parts, metal processing, metal processing equipment, etc., can solve the problems that radial shaving cutters cannot be processed, dislocation distribution cannot be formed, and the main movement efficiency of slotting machines is low. , to achieve the effect of easy machine adjustment, rich functions and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

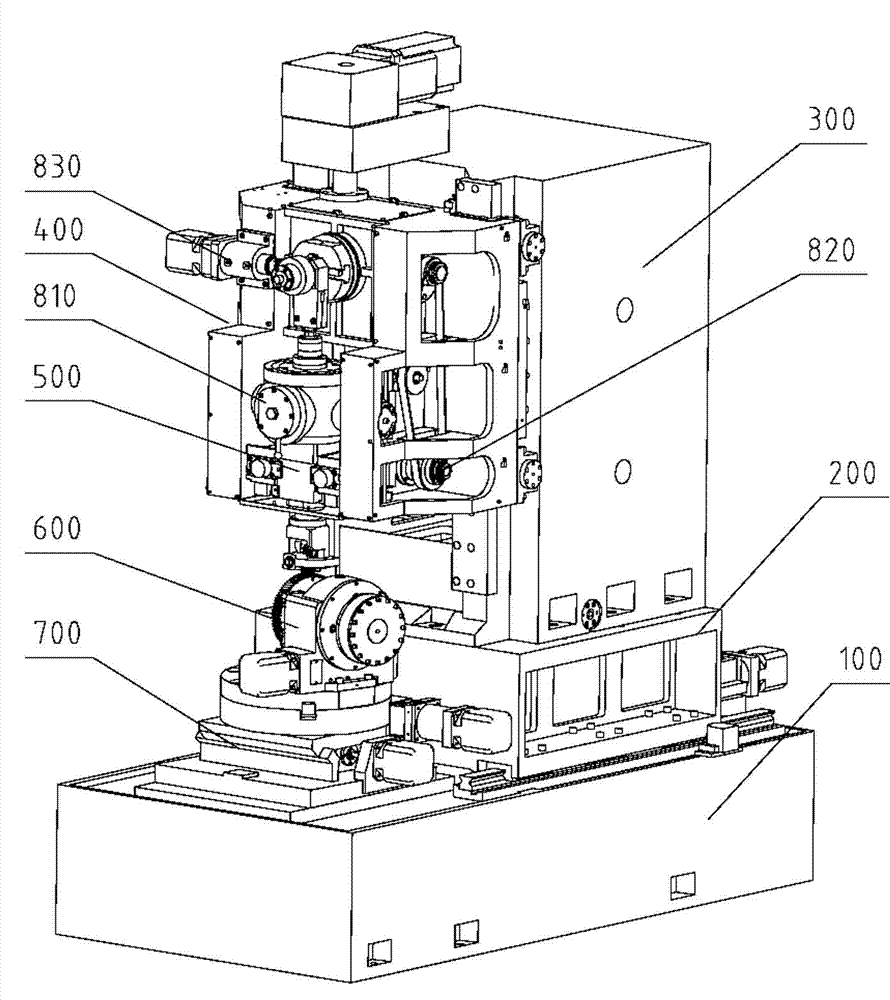

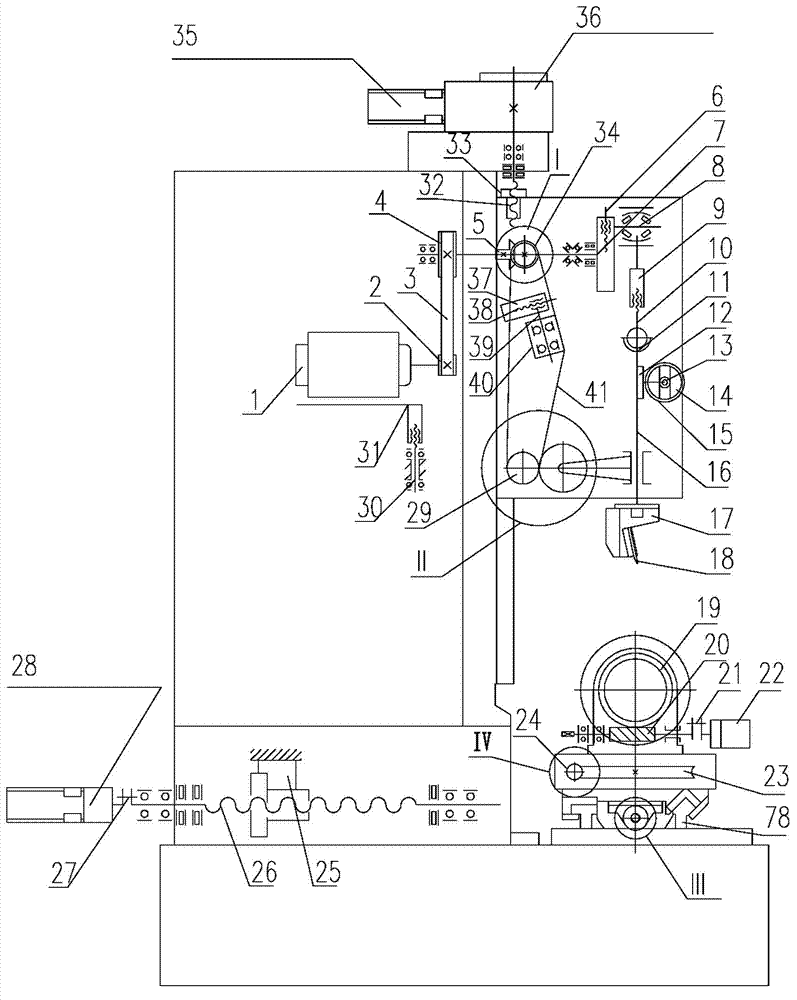

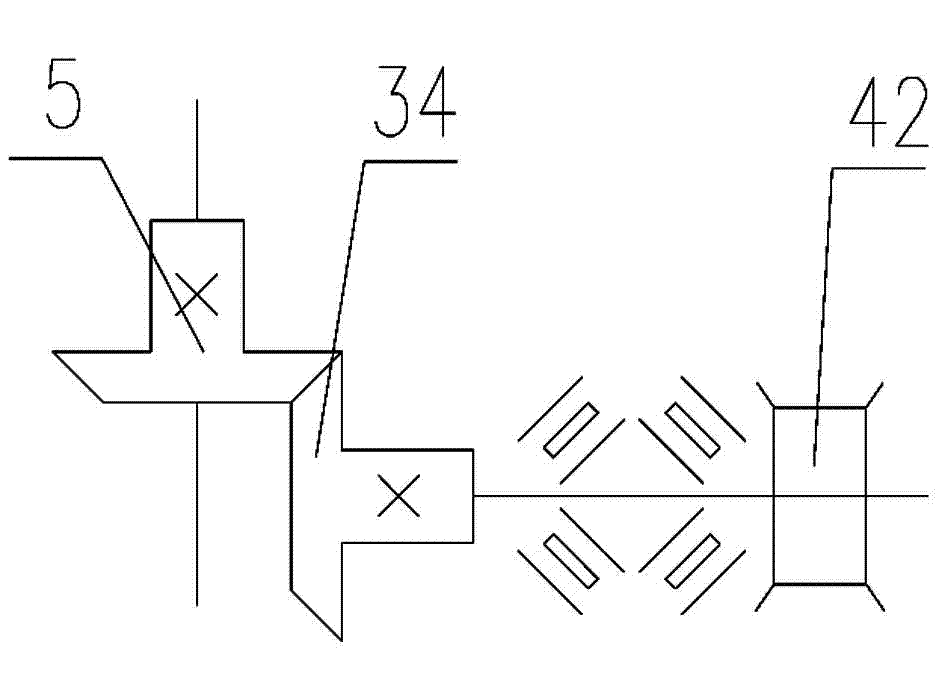

[0031]See attached figure 1 As shown, a machine tool for processing chip pockets of gear shaving cutters, which includes a bed 100, a middle bed 200, a column 300, a slide 400, a tool holder body assembly 500, an indexing head 600, and a transverse slide 700 , and a numerical control system and a hydraulic system, characterized in that: the bed is fixed to the foundation, the middle bed and the transverse sliding table are arranged at both ends of the upper side of the bed, and a middle bed is arranged between the middle bed and the bed Horizontal moving mechanism, with a column on the middle bed, a sliding seat on the side of the column, and a tool holder body assembly on the sliding seat; an indexing head is installed on the horizontal slide table, and the upper and lower positions of the indexing head and the tool holder body assembly correspond ; The sliding seat is provided with a main drive mechanism, an arbitrary helical angle compensation mechanism 810, a micro-knife m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com